Harvesting & Cultivation:

Cultivation is the first step in the process for production of algae to usable biofuels. There are two main types of algae, macroalgae and microalgae. Macroalgae are bigger organisms (e.g. seaweed) and have less potential for cultivation, although some studies have looked into open ocean or on-shore cultivation processes. Cultivation is more widely associated with microalgae. There are two ways to grow microalgae: autotrophic, and heterotrophic (Algae Basics).

- Autotrophic microalgae: require inorganic compounds & a light energy source for growing along if CO2. The propriety that autotrophic microalgae require CO2 is very advantageous due to the fact that CO2 is a greenhouse gas and recycling CO2 emissions for growing algae is clearly a win-win way in an attempt to reduce greenhouse gas emissions.

- Heterotrophic: often grown in large fermenters; non photo-synthetic and require external source (e.g. sugar or starch).

Autotrophic microalgae is the more researched of the two methods for algae cultivation concerning biofuels mostly due to the fact that it consumes CO2 and does not require an external source like sugar or starch. There are two primary ways to grow autotrophic microalgae for biofuels: open pond cultivation and within a photobioreactor. Both operations have key benefits and drawbacks. The following is a general analysis of these benefits and drawbacks:

- Open Pond

- Pros: Low capital cost

- Cons: Potential for eutrophication making it difficult for fish to grow, ability for algae deeper in the pond to recieve light needed for cell division (growth), water use: open ponds utilize water that may be used for other areas.

- Photobioreactor

- Pros: Little to no land/water use, can potentially allow for easier and better control of the algae growth (Slade)

- Cons: High capital cost

Cultivation Costs (autotrophic):

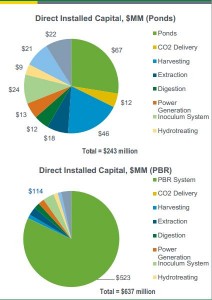

Energy input associated with cultivation corresponds to 20-30% of total algae production costs. Figure 1 shows the breakdown of costs for different sources of algae generation. The figure shows that Photobioreactors (PBR) have a much greater direct installed capital cost than cultivating algae using open pond (OP) techniques.

There are various methods for cultivating algae for biofuels and essentially all are utilized. The challenge now is to determine a best practice system for harvesting algae for biofuels. Some have even began to try to implement hybrid systems for autotrophic algae growth that attempt to utilize the benifits of both PBR and open pond algae cultivation (Algae Basics).

(Composed by Eli Karp, edited by Robert King)

References:

Algae Basics. (n.d.). Retrieved May 3, 2015, from http://allaboutalgae.com/

Behera et al., S. (2015). Scopres of algae as third generation biofuels. Bioengineering and Biotechnology, 2(90). Retrieved April 15, 2015, from Frontiers in.

Davis et al., R. (2011). Techno-economic analysis of autrophic microalgae for fuel production. Applied Energy, 88, 3524-3531. Retrieved April 19, 2015, from Elsevier.

Slade, R., & Bauen, A. (2013). Micro-algae cultivation for biofuels: Cost, energy balance, environmental impacts and future prospects. Biomass and Bioenergy, 53, 29-38. Retrieved May 4, 2015.