|

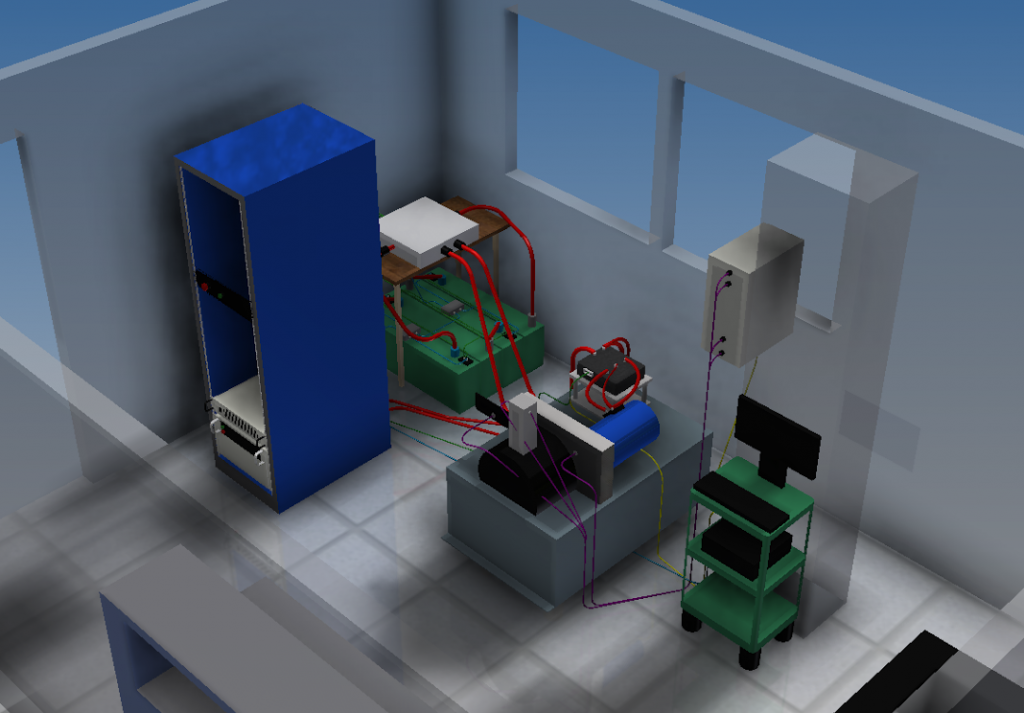

| A computer generated image of the Dynamometer room, AEC 401 |

This page documents the design efforts accomplished during the Spring 2015 semester. The system was successfully delivered, consisting of an: electric motor, high voltage power supply, cooling system, and data acquisition software.

Project Documentation

Listed below is documentation for all of the systems designed by the DYNO group.

- LFEV Dynamometer Final System Design

- LFEV Dynamometer Maintenance Manual

- LFEV Dynamometer Software/CAN Interface

Huff Documentation

Listed below is the documentation provided with the Huff Dynamometer Box.

- Huff Oil Valve (CAT HY14-3200)

- Huff Box Layout (1/2) (ISO-RACK08)

- Huff Box Layout (2/2) (SSR-RACK08)

- Load Cell (LCCE)

- Strain Gauge Acquisition Card (SCM5B38N)

- Tachometer Acquisition Card (SCM5B45)

- Throttle Voltage Output Card (SCM5B49)

- MCDAQ USB-7000 Series Datasheet

- MCDAQ USB-7204 User Manual

Project Deliverables

PDR Deliverables

D000 – Preliminary Design Report

D004 – Acceptance Test Plan – Outline

PDR Presentation

D004 – Acceptance Test Plan – Draft

Updated Work Breakdown Schedule

D002 – Dyno User Manual

QA Tests

QA Test- 4/23

QA Test 1 – 4/30

QA Test 2 – 4/30

QA Test 3 – 4/30

QA Test 4 – 4/30

QA Test – 5/8 – 10 HP Temp Rise Test

Inspection Report

Inspection Report

ATP Tests

PDF | CSV

10 HP Test | 10 HP Test

50 sweep | 50 sweep

60 – 0 sweep | 60 – 0 sweep

100 sweep | 100 sweep

sweep | sweep

Test 1 | Test 1

Test 2 | Test 2

Test 3 | Test 3

Calibration

RPM Calibration Data

Torque Calibration Data

T001-2 Analysis

D011 – Dyno Calibration and Accuracy

Acceptance Test Report

D004 – Acceptance Test Plan

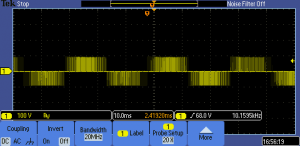

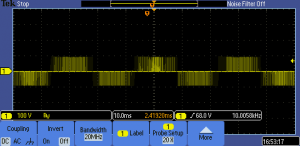

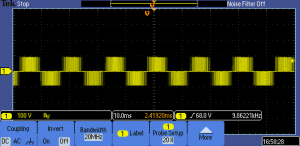

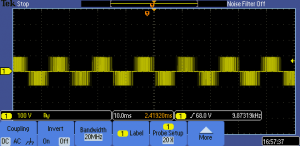

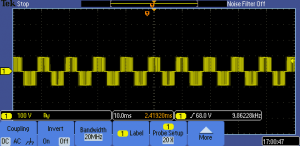

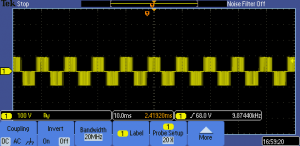

| Motor Scope Shots | |

| 2000 RPM High Load | 2000 RPM Low Load |

|

|

| 2000 RPM High Load | 2000 RPM Low Load |

|

|

| 3000 RPM High Load | 3000 RPM Low Load |

|

|