Introduction

Season extension technologies refer to anything that allows a crop to be grown and harvested beyond its normal outdoor growing season and harvesting window. These technologies have been utilized for hundreds of years and provide significant benefit when properly implemented; greenhouses, in particular gothic greenhouses, are one such technology. Resetting the Table in the Lehigh Valley addresses the technical constraint at hand in saying:

“A major limit to the amount of food produced in the Lehigh Valley is the temperate climate. This climate only allows farmers to produce food for around 4 to 6 month (half of spring, summer, and half of fall) of the year and is dependent on the weather from year to year” (EGRS/EVST 373, 2014).

A greenhouse, as the name implies, is a technology which takes advantage of the greenhouse effect as a means of effectively heating a growing space. In order to maximize efficiency while at the same time minimizing costs, we must consider the multitude of possible design alternatives that factor into the final structure. These considerations range from broader contexts of greenhouse orientation and location to some of the more minute details including material considerations and climate control.

Beyond the information provided by the previous two greenhouse capstone reports, we have also obtained a considerable amount of insight on the design from Sarah Edmonds, the manager at LaFarm. In this section, we take a look at 3 possible alternatives for greenhouse construction.

Technical Analysis:

Structure:

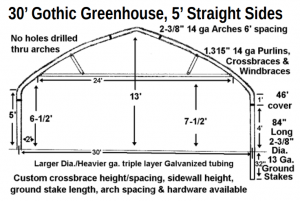

At this stage in the LaFarm Greenhouse Initiative, our focus closes in on the specifics of greenhouse implementation. Upon recommendation from the 2015 & 2016 Capstone reports, we are pursuing a 30’x96’ gothic style greenhouse with 5′ walls, to be purchased from locally sourced greenhouse vendor (EGRS Capstone Report, 2015).

Heating:

We support the prior capstone reports in recommending to leverage twice-tempered climate control technology for installation at LaFarm. This technology creates two distinct climate zones by reducing the volume of air being heated to support plant growth. Zone 1 can be considered the open air space of the greenhouse. Zone 2 is considered the smaller volume of air that surrounds the seedlings beneath the climate covering.Since we are able to reduce the required volume of air to be heated, we can heat the soil beneath the crops as an effective alternative to maintaining optimal growing conditions. This method of climate control is more effective and efficient than heating the entire volume of the greenhouse space. Additionally, twice-tempered climate technology reduces the minimum required zone 1 temperature necessary for crop growth, reducing the energy required to heat the greenhouse space. A simplified version of this heating technique is demonstrated in the image to the right.

Location/Orientation:

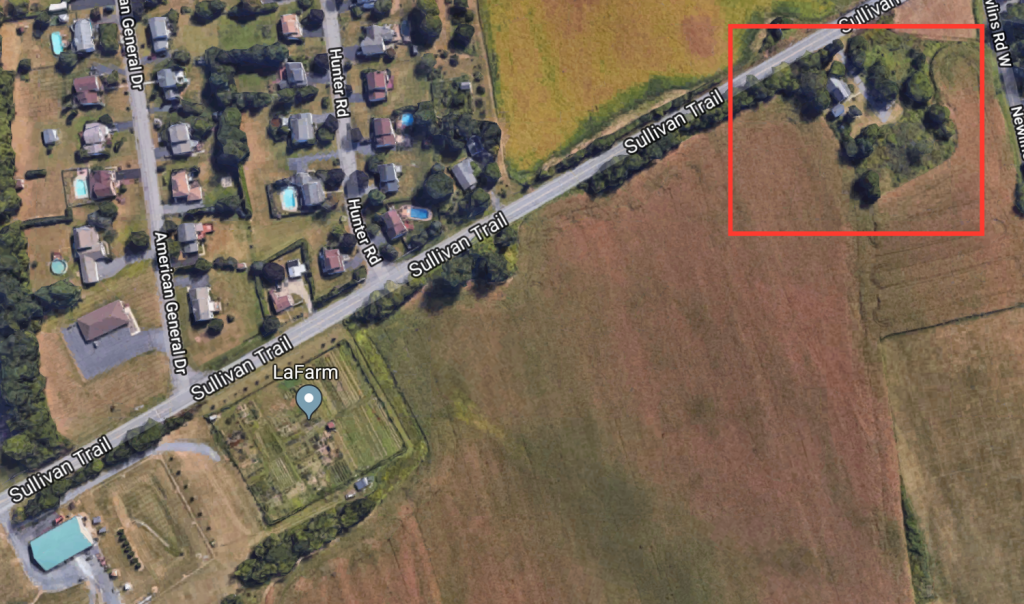

The first alternative considers an on-grid greenhouse structure located on the plot adjacent to the facilities building, just south of Rapport Field. This location is highlighted in the yellow region below:

Source: Google Maps

Currently, this land serves no purpose, other than storing mulch for Facilities Operations. We envision the greenhouse oriented lengthwise east-west, leaving the south roof exposed to the sun for maximum thermal efficiency. This orientation also lends itself well to the utilization of roll-up sides on the north & south walls, which take advantage of the prevailing northerly wind to aid in air circulation. Refer to the photo collage below for a variety of angles of this location:

Various iPhone images of LaFarm

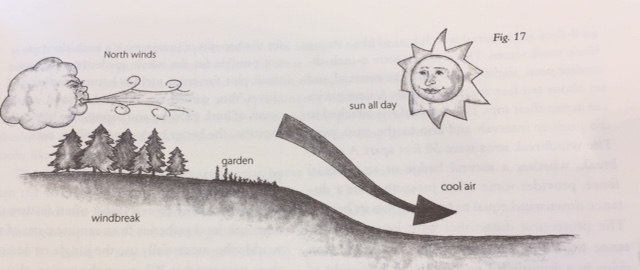

Due to its situation atop a small hill, this location would be able to leverage a geographical phenomenon that is outlined in Elliot Coleman’s Four Season Harvest. As seen in an illustration of his below, a greenhouse situated atop a hill would be able to effortlessly utilize prevailing winds generated from this elevation difference.

(Coleman, 1999)

This technique would be paramount in effective pest management, ultimately minimizing crop loss due and infestation from the proper amount of ventilation. In addition, since the site is at the top of a hill, the land is relatively flat and thus requires little to no landscaping/grading prior to construction. Also, this site takes advantage of its proximity to the facilities building, leaving the possibility for the greenhouse to be on the grid and lending access 4 season, city water. Lastly, this location is in close proximity to the LaFarm access road, as well as is directly adjacent to LaFarm allowing for easy access year round.

Source: Google Maps

Our second alternative follows the same direction as the first in terms of proposed location, however, looks into the possibility of utilizing solar power (and other renewable energy sources) to supplement electricity to the greenhouse. As a part of the environmental campus next to the Facilities building, Lafayette College owns two solar panels which feed energy to Grossman House on-campus. We see this as an opportunity to expand the solar capacity of this facility to supplement the energy demands of the greenhouse and its operation. The addition of solar panels is in alignment with the vision of Lafayette & LaFarm in terms of sustainability, which would further incentivize greenhouse construction. This aspect, however, complicates the implementation of the greenhouse in the short term, detracting from our group’s immediate goal.

Our final alternative suggests an on-grid greenhouse adjacent to the Newlins farmhouse plot, as seen in the image below. This alternative aligns with the visions of the 2017 Environmental Studies Capstone report, which map out the future expansion of LaFarm in the long run.

Source: Google Maps

This site is nearly ¼ mile from the actual farm itself. This farmhouse would be an on-the-grid option, utilizing 3 season well water on site. While this location aligns with the vision set for phase III of LaFarm expansion, it offers challenges associated with its feasibility and implementation. While this location does allow for easy access via Newlins Rd W, the site requires preparation, particularly intensive excavation and gradation in order to begin construction. While this does not discount this alternative from consideration, it is important to understand how this affects the overall feasibility of the project. An additional downside to this location results from its distance from the grow site at LaFarm. This distance complicates the process of transplanting seeds from greenhouse to grow site in the early spring, requiring driving multiple trips in order to bring the seedlings outside. While this is not a deal breaker, it is important to consider how this factors into the overall sustainability of the greenhouse, as well as its carbon footprint.

Irrigation:

The existence of a 4-season water source located near at the Facilities Operations building provides a convenient way to consistently hydrate crops in the proposed greenhouse. The two primary methods of irrigation are broken down into manual and automatic systems. Many greenhouses leverage a sprinkler system to deliver water to a large number of plants in a short amount of time. From a manual perspective, some farmers use a traditional hose and spigot technique. When interfacing with Sarah Edmonds, she expressed her preference of a manual system for simplicity sake. This technique can be seen in the image below, and our conclusion is elaborated upon in the recommendation portion of this section.

Ventilation:

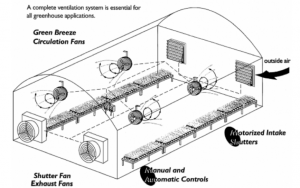

As discussed earlier in this technical analysis, ventilation plays an imperative role in pest management and climate control. After careful deliberation with Sarah Edmonds, it was established that one of the best ways to sustainably manage air movement in a greenhouse would be to leverage as much natural breeze as possible. This tactic would minimize the necessity for electric-powered ventilation systems. For this reason, our capstone group and Sarah believe that encompassing roll-up sides in conjunction with positioning the greenhouse atop a hill (As described above in “location”) would be the most efficient and sustainable strategy for ventilation. That being said, this technique is only viable in mild months when the air is warm enough for plants to tolerate. Consequently, Ms. Edmonds said the best way to overcome this ventilation challenge would be to have supplemental fans within the greenhouse. She suggested integrating eight 12” fans (four on each side), two exhaust fans on one end, and two air vents on the opposite end in order to properly circulated the air (Sarah Edmonds, personal communication, October 18, 2017). This model was presented in the Nolt’s Greenhouse Supply catalog, as depicted in the image below.

Nolt’s Greenhouse Supply

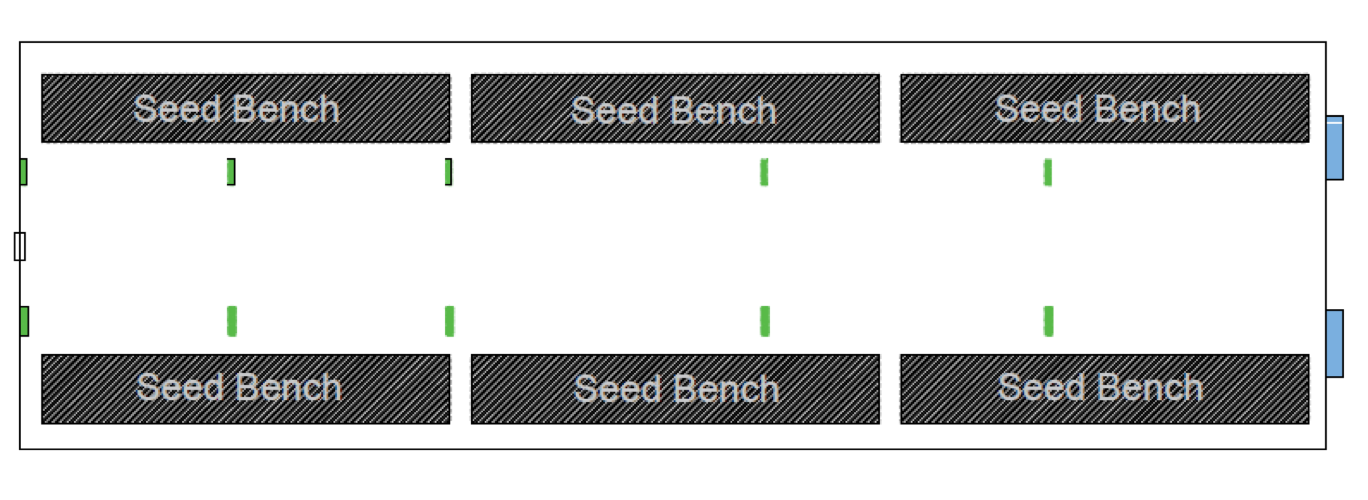

Furthermore, our group has generated a preliminary footprint of the footprint for consideration. This graphic is to-scale and encompasses the eight circulation fans, two exhaust fans, and two air vents. Additionally, it includes six 5’x30′ seed benches, as per the recommendation of Sarah Edmonds. This ventilation system would sufficiently circulate the air within the greenhouse when the weather does not permit the usage of roll-up sides.

Source: Student CAD Drawing

Recommendations:

Each of the given alternatives provides a unique set of benefits and drawbacks to constructing the LaFarm greenhouse. While alternative 3 offers convenience for the farm keeper (living directly adjacent to the greenhouse gives 24 hr easy access) in monitoring the greenhouse, its location away from the planting area at LaFarm provides challenges come time to transplant the sprouts. The second alternative is a best-case-scenario option, utilizing renewable energy sources to help offset the energy demands of the greenhouse. While this would be ideal, there needs to be a separate, in-depth analysis of the technical and economic feasibility of their implementation, which is beyond the scope of our project. This is not to say that they should not be considered later on, as a separate project in itself. This leads us to recommend the alternative 1 for greenhouse construction. This alternative provides optimal location, both in terms of accessibility and functionality. Additionally, this location lends itself well to the future integration of solar panels and other renewable energy sources for supplemental energy supply.

In order to fully understand the technical requirements of the proposed greenhouse, we must look at the operational systems required for normal use, mainly heating and irrigation. As mentioned before, there are ways to increase the thermal efficiency of a greenhouse structure through strategic placement and orientation however it is impossible to completely offset the need for supplemental climate control systems. Especially in the cold of late winter/early spring, it is necessary to provide supplemental heat to the structure. A simple solution to this would be to incorporate electric/gas powered heating units into the greenhouse design, however this method is inefficient, costly, and conflicts with LaFarm’s vision of sustainability. Through extensive research, our group has concluded that utilization of twice tempered climate control technology allows for more efficient climate control while utilizing less energy.

Another crucial component to consider for successful greenhouse operation is irrigation and water supply systems. As mentioned earlier in this analysis, one of the main factors in determining optimal location was the existence of 4 season water at the site. Bringing this water into the greenhouse for functional use provides another challenge. At first, we considered the possibility of installing an automated irrigation system for installation. While this would automate the growing process to some extent, we determined that such a system would be beyond the scope of our project and could possibly detract from the mission of the greenhouse. We have concluded that, for our purposes, the ideal irrigation system would consist of a winterized, frost proof hydrant, coupled with watering fixtures and hoses for use in watering crops. We see this as a benefit over an automated irrigation system in two ways. The automatic irrigation system, while convenient, retains a certain level of complexity which leaves the opportunity for technical issues down the road. We feel that in this specific case, simplicity should be prioritized over convenience in an attempt to mitigate future problems that might affect the overall success of the project. Additionally, we feel that the implementation of an automated irrigation system takes away from the role the student plays at LaFarm and, in a sense, detracts from LaFarm’s mission as a student-run agricultural organization. We feel that as such, LaFarm & its facilities should foster as many learning opportunities as possible and are proposing the consideration of further engagement opportunities.

Part of the vision for the LaFarm greenhouse envisions it as an educational space for students, faculty, and community members. We, therefore, recommend that a secondary educational structure be considered alongside the construction of the greenhouse. This classroom structure does not have to be permanent and can be as simple as a modular, temporary space adjacent to the greenhouse structure. Additionally, the greenhouse itself can be utilized as a learning space and can be set to emulate a lab setting for educational use. For this aspect of the greenhouse project, we are recommending that a temporary, mobile structure be situated along the north wall of the greenhouse. We considered the possibility of constructing a permanent structure on-site to serve as an educational space, but concluded that a temporary structure better fits the short-term goals of LaFarm while still supporting its long-term vision.

Next Section: Economic Context