Challenge:

Due to the nature and the bylaws of LaFarm, it can be difficult to classify the return on investment of adding chickens. There will be many different costs and benefits associated with the addition of chickens to Lafarm. Our economic analysis aims to provide the necessary information to make a recommendation for the financial plan related to the chickens.

Introduction:

Implementing a chicken tractor system is not as simple as buying a few chickens and putting them in a moveable coop. The breed of chicken must be chosen in regard to the problem that is to be solved, and the tractor must be able to properly house this breed. Additionally, the system needs to be structured to match the goals and objectives that Lafarm wishes to promote. When all of this is considered, even if every criterion for the perfect system is met, it still can only happen if the system is economically feasible. An in depth economic analysis provides an array of possible solutions, so that the best solution can be tailored to the particular user.

Initial Costs:

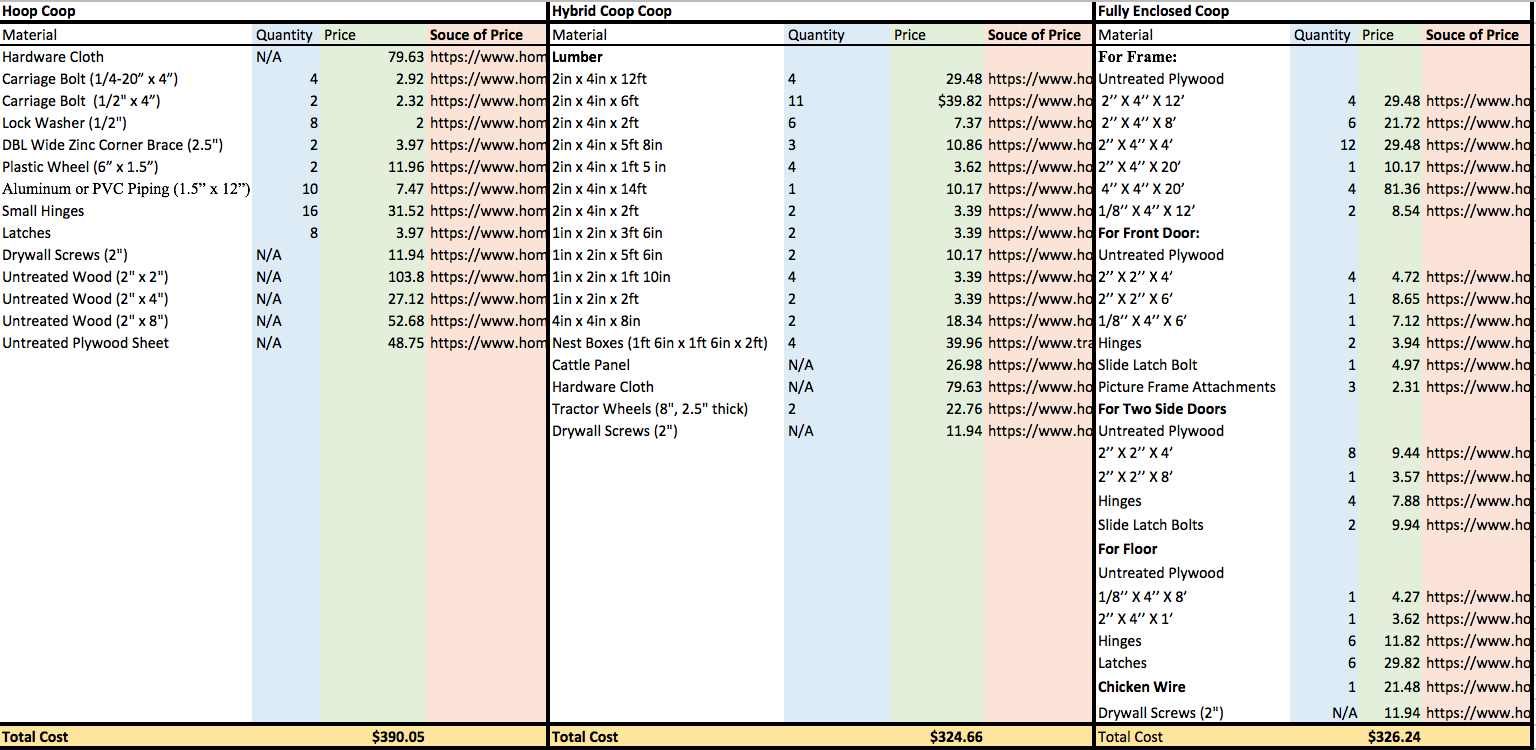

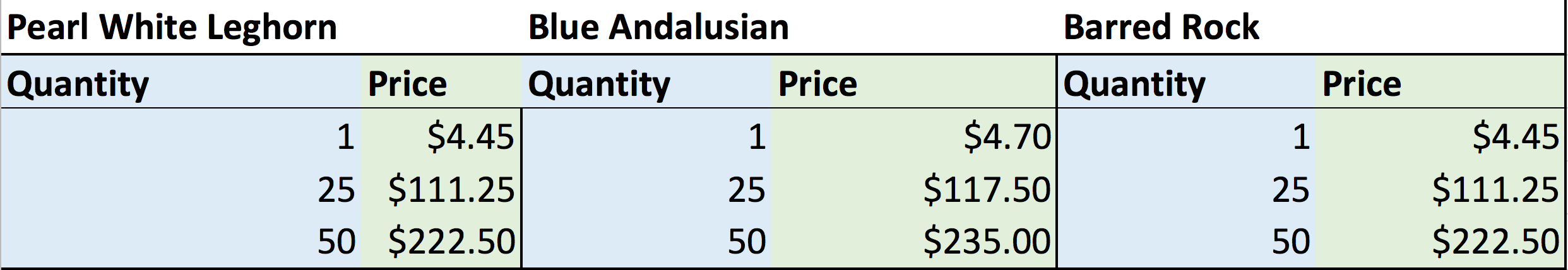

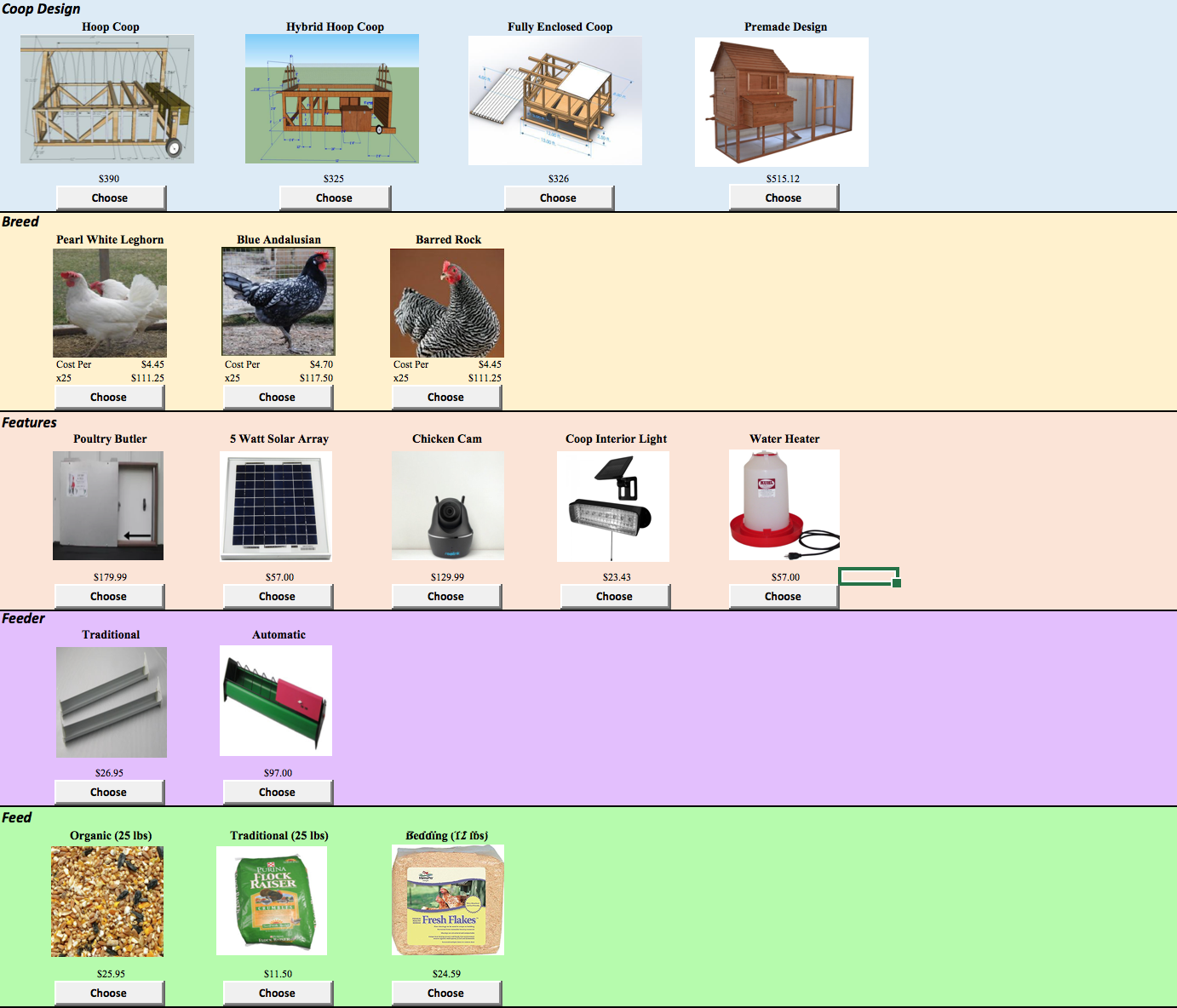

Four structural designs for the chicken tractor were considered for this system. The first design is a premade coop which requires no assembly at a base cost of $484.99 (houzz, 2017). The only modifications which would need to be made to make this a mobile coop are the addition of two retractable tractor wheels and a handle for which to pull it. With these additions, the cost totals at $515.12 (Home Depot, 2017). The remaining three designs were developed as a project at Worcester Polytechnic Institute. The first design, the Hoop Coop, was estimated to cost about $240 by the project team, but after analyzing their cost breakdown there was much ambiguity amongst the quantities of materials (Cole, DeLuca, Zielinski, 2015). After reviewing and reassessing the costs, our team estimated the actual cost to be $390.05 (Home Depot, 2017). The second design, the Hybrid Hoop Coop, replaces the larger chicken wire fence with an increased amount of lumber. Though the cost was estimated to be higher than the Hoop Coop, by manually cutting larger pieces of wood the cost decreases to a total of $324.66 (Home Depot, 2017). The last coop design, the Fully Enclosed Coop offered the greatest protection out of the four, and was also estimated to cost above $400 (Cole, DeLuca, Zielinski, 2015). After pricing out the necessary materials, the estimated cost came to a total of $326.24, less than two dollars more than the Hybrid Hoop Coop (Home Depot, 2017). All three systems were estimated using the costs of materials from homedepot.com. These costs can potentially be further decreased by purchasing the lumber in a bulk order of one size and then cut to the necessary dimensions.

The aforementioned costs are solely for the structure of the chicken tractor, there are many other features necessary for the system to operate successfully. To keep predators from entering the mobile coop, a Poultry Butler door is to be installed, which will open and close based on a light sensor, at the cost of $179.99 (Poultry Butler, 2017). Additionally, to the predators, the chickens are also at risk to the harsh winter climate. While the chickens are able to survive in temperatures as cold as -10 degrees Fahrenheit, the water dispenser within the coop will freeze. To prevent this from happening a water dispenser with a built-in heater will be installed to assure constant water availability costing $57 (Strombergs, 2017). Having these features in place can give the community some peace of mind that the chickens will live comfortably, but if there are any doubt community members can view the chicken cam to check in on the coop. By installing a wireless Reolink camera, at a cost of $129.99, anyone can pull up a webpage and view the stream of the coop (Reolink, 2017). All of these features will require a power source, and to parallel the ideas of Lafarm, a five-watt solar panel will power the door, water heater, and whichever other features are chosen to be installed costing only $57 (BatteryStuff.com, 2017). The one feature which will not be reliant on the five-watt panel is the solar powered light which will be inside the coop, as this has its own panel to power itself, costing only $23.43 (Walmart, 2017).

The 2017 EVST Capstone researched into a few particular breeds of chickens which could be introduced to Lafarm when conducting their analysis, and also determined the appropriate quantity of chickens to implement a coop would be 25. The three breeds were chosen due to their low-cost replacement, widespread availability, and egg production. The Pearl White Leghorn costs $4.45 per chick, being the best white egg layer out of the three, and 25 totals to a cost of $111 (Strombergs, 2017). The Barred Rock, being able to produce brown eggs, costs $4.70 per chick and would total to $118 (Strombergs, 2017). The Blue Andalusian costs $4.70 per chick, being the most expensive of the three options, and totals to $118 (Strombergs, 2017). The cost difference between all three chicks is minimal, so implementing any of these with the tractor system would be feasible. It is important to note that the chicks are cheaper than their adult counterparts. To raise a chick requires them to be kept inside for a few weeks (inside being a barn, shed, or inside a house). The cost of raising the chick is factored into the price of an adult chicken, but given the design of our potential tractor system, it is feasible to house the chicks as the coop will have the proper insulation.

Once installed and fully operational, the chicken tractor will continue to have alternative monthly costs. Bedding and feed will be the two main recurring costs, however these materials, if stored correctly, can be bought in bulk in order to cut costs. In addition to its daily grazing consumption, a chicken on average requires 1/4 pound of feed per day (Hoskins). Assuming an initial flock size of 25 chickens, and a price of $11.50 per 25 pounds for traditional and $25.95 per 25 pounds for organic feed we can predict an average yearly cost of $1050 or $2368, respectively (Amazon, 2017). Along with food, chickens require new bedding. Bedding serves many different purposes; drying the chicken manure as well as keeping the chickens occupied. Holding the same assumptions, and a cost of $24.59 we predict an average yearly cost of $295 per year for the coop bedding.

Non-Monetary Costs and Benefits:

Although it is important to identify all the monetary costs in the system, there are other costs and benefits. Deciding to choose chicks over adult chickens saves money, but at the same time will require more hours of labor to monitor and care for them. Resources from other Lafarm activities will have to be transferred to the chickens until they are at an appropriate age. Even though this will require resources to be reallocated, Lafarm now expands to a whole new level of production with the addition of livestock. The chickens being used to self-fertilize the soil also shows the progressiveness of the farm, and bolsters Lafayette College’s green initiative. There is also the potential for a greater connection between the community and the chickens when they are bought as chicks. Through raising an animal into its adult age, students may become more connected with the chickens and consequently more devoted to Lafarm.

When looking at the chicken tractor system as a timeline, the first step after the feasibility report would be the design and construction of a coop with only the necessary factors. These factors would include the coop itself, along with the poultry butler door and the five-watt solar panel. By implementing only the necessary factors, the price can be minimized while still being operational to the maximum level of efficiency. The materials for each system are accessible, but will require construction to compile. Mechanical Engineers or Engineering Studies majors, or even both together, can take part in constructing the coop and implementing it into Lafarm. A course could be offered for the design and construction of the system, where the students go pick up the materials from Home Depot and assemble the tractor on site at Lafarm. Once the specific design is chosen, the construction could be completed in a matter of days.

Conclusion

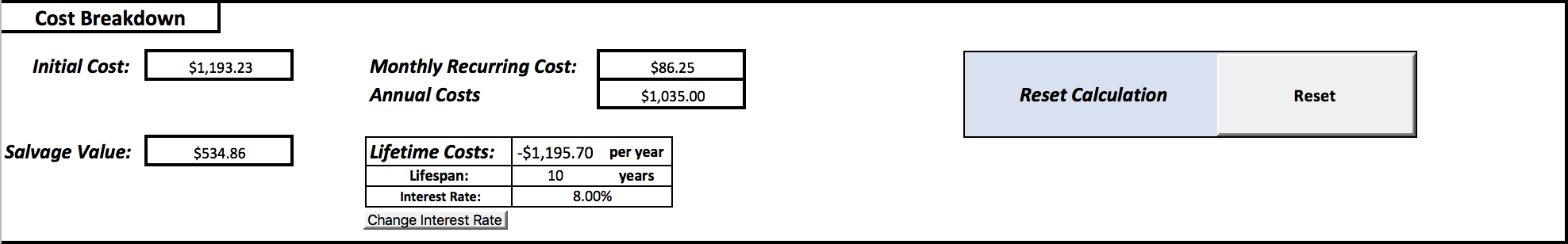

Going forward, our team wanted to be sure that the next group to continue this project had all the resources for this economic analysis readily available. To compile all of the data for this section into one place, an excel spreadsheet was created which stores all economic data and the sources containing the prices and location which they can be ordered. To not force the hand of the next group on which direction the chicken tractor system should go, each part of the system can be chosen from a variety of options, to allow a customizable experience. The three varying coop designs, the three breeds of chickens, each feature, feeder, and feed, can all be decided to allow the user to design the tractor to meet whichever goals they prioritize. Additionally, the cost breakdown of the tractors can be found in this document, where each material and the necessary quantity is listed alongside the hyperlink for purchasing. The costs will include a an initial cost, a recurring cost, and salvage value; all of this will also be annualized along the predicted lifetime of the system. We believe having these calculations programmed through excel macros will provide future groups with predetermined and justified initial and annualized costs, which may accelerate the schedule for implementation on Lafarm.

Sample System Design:

Sample Cost Breakdown:

To View Chicken Tractor Economics Calculator: