Technical Analysis (GH)

ABSTRACT:

While heat and electricity are not necessary for the functioning of a productive greenhouse, technologies that require both variables can provide distinct increases in greenhouse value. The purpose of our technical analysis is offer and analyze heat and electric technology-systems for use at LaFarm’s hypothetical greenhouse. We ultimately contribute an analysis that recommends technologies and technology-systems that can most feasibly and appropriately be implemented to a theoretical greenhouse at LaFarm. First, we investigate how variable physical parameters influence the feasibility of our technology-system. Then, we identify technologies capable of delivering specified environmental modifications to understand how they can be integrated in a system. Fundamental to our technical analysis is an understanding and communication of why a LaFarm greenhouse has specific environmental needs.

Specifically, we investigate why we are providing heat to a 30’ x 96’ gothic greenhouse in Easton, PA and consider how temperature, location of temperature application, and planting schedule can be adjusted to maximize greenhouse production capabilities. We consult greenhouse designers and examine existing greenhouses to develop an understanding of the available technology and strategies used for heating and electric systems. We conduct a theoretical complete heat loss analysis for the specified LaFarm greenhouse in order to understand the energy loadings that our technology-system will require for adjustable forcings in environmental conditions. We integrate individual technologies, strategies and modifications to construct viable systems of technology for heat and electricity supply at LaFarm. Finally, we evaluate the various energy-systems using evaluative criteria in order to provide recommendations for specific heating systems for LaFarm’s Greenhouse.

Background, Thought Process, and Conclusions: Framing the problem by considering greenhouse intended use in a heating and electrical context

Season-extension technologies range from basic soil modifications and plastic row covers to greenhouses with complete environmental control systems. Resetting the Table in the Lehigh Valley seems to cast an image that all full-sized greenhouses are technologies that sit in the upper extrema of environmental modification in farming. This is an idea that has been substantiated in our research by various industry experts including Eliot Coleman, Chris Callahan, the Rodale Institute among others.

A defining part of our our project is that the communication with stakeholders whose vision our project is intended to supplement was somewhat minimal. For this reason, we want to be diligent not to overstep our boundaries, and to understand the limits in which our project can be useful. In particular, this means that we have to make many critically important assumptions, but in addition, we must be very clear to acknowledge when an assumption is being made.

The gothic greenhouse that the previous capstone group recommended would be categorized as a middle-tier greenhouse and would thus fall into a category of being just short of the most complex of technology being implemented on the commercial level of organic farming. The general purpose of a gothic greenhouse is to create an artificial environment that supports highly efficient crop growth. Typical of a gothic greenhouse is fully regulated temperature and lighting control throughout the greenhouse which is provided to gain year-round access to seed-starting, experiments and to house substantial year-round growing capacity. From our contact with both the manager of LaFarm, and the previous capstone, we learned that while a gothic greenhouse is desired, there is not an intent to immediately utilize the maximum technological capabilities of the gothic greenhouse. Our impression is that the greenhouse would be primarily used as an unheated shelter against harsh winds, rain and snow, with additional heat applied specifically for seed-starting at various times of the year.

For our project, we were tasked to investigate creative and resourceful methods of providing heat to seedlings in an efficient manner. Our advisor urged us to develop solutions that were on a scale that could be implemented off grid. The farming manager communicated that there was not an expectation for artificial light to be necessary. We were asked to build from the idea that in order to effectively grow seedlings, we might only heat the soil, and not necessarily the air. Naturally, we wanted to know how this could be, and why this was instructed before devising solutions that could satisfy these constraints. Thus, a major concept that we want to understand is whether or not technical boundaries actually limit heating the entire greenhouse. After all, if it were possible to be both off-grid and carbon neutral while heating the entire greenhouse, the potential usages and value of the greenhouse would skyrocket.

So with that, the technical analysis began in a decidedly big-picture way in order to get back to the original question from a more informed standpoint. We started by using a thermodynamic approach to attempt to define the energy loss of the entire system: a 30’ x 96’ gothic greenhouse. We tried to find experimental data based on greenhouses of the same approximate size that are scattered around the region. We found that farms are not particularly concerned with the amount of heat required for their greenhouses so much as their general heating bills, and that they utilized greenhouse heating experts for this type of thinking. We connected with one particular expert who provided a plethora of experimental data on heat usages for greenhouses.

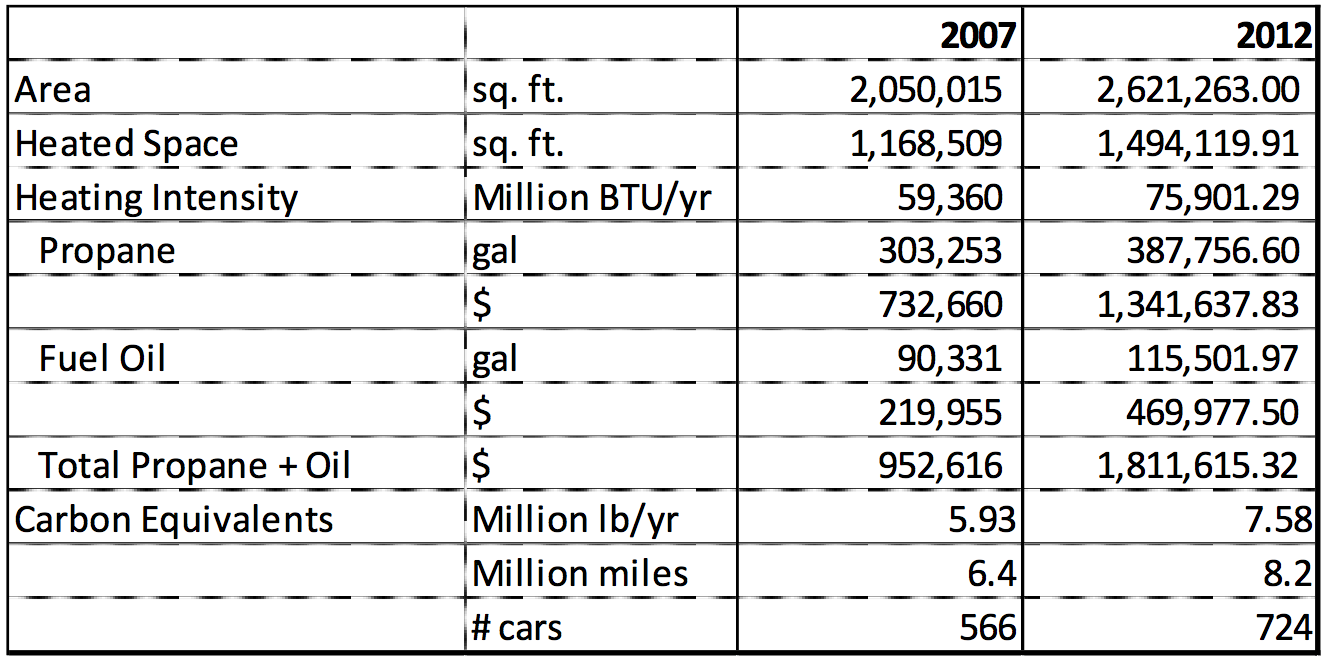

Figure 1: Compiled Vermont Greenhouse Heating Data from Biomass Heating Study

Chris Callahan, went on to send us in the direction of undertaking the creation of a theoretical analysis of the complete heat loss associated with a greenhouse of our specifications. We utilized the Complete Heat Loss Analysis method outlined by Alrich and Bartok in Greenhouse Engineering. We used dry bulb temperatures from Typical Meteorological Year (TMY3) data provided by the National Renewable Energy Lab and based our calculations off of the coldest hour, coldest 1% of hours, coldest 2% of hours, and coldest 5% of hours recorded from ~8500 data points. While tabulating data, we observe that if we were to avoid seed-starting in January and February, we could cut heating costs by around 40%. Ultimately, back-of-the-envelop calculations following the complete heat loss analysis revealed that it would take an infeasible magnitude of carbon-neutral energy harvesters (wind turbines, photo-voltaic cells etc.) to provide heat for the entire greenhouse throughout the year in an off-grid manner. More significantly, the heat loss analysis confronted us with a slew of undefined but important variables that we had not previously recognized.

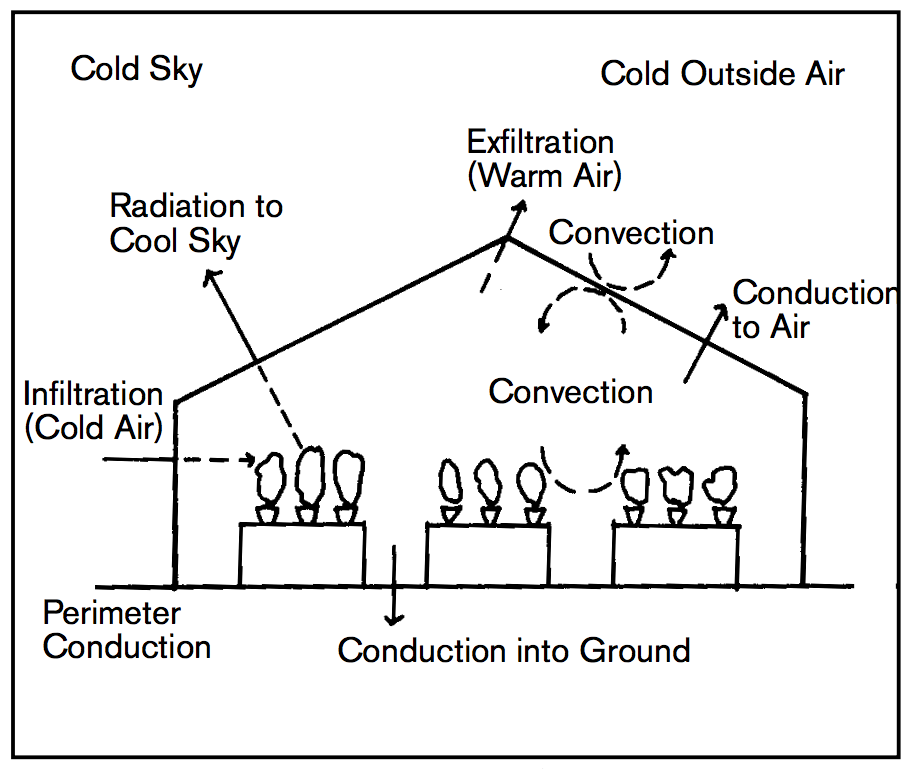

Figure 2: Greenhouse Heat Losses Diagram from Greenhouse Engineering Book

Firstly, in order to quantify the amount of heat and appropriate methods for heating the seedlings, we had to define not only the location that the heat would be applied, but also the temperature that that needed to be maintained. Second, we need to consider how large of an area will require heating; it is a tall task to give any useful educated recommendations for heating technologies without understanding the amount of space the seedlings will require at any given time. In order to maximize the efficiency of heating, we should ideally consider maximum area being heated, as well as average area being heated in order to decide how we should plan a heat system. Finally, we needed to consider how much additional heating should be implemented in order to plan for heat losses due to inefficiencies.

Through adjusting various heat loss variables associated with heating the entire greenhouse, it became very clear that modeling thermodynamic losses from heating soil rather than air would be very complex to undertake and unreasonable given the time constraints and academic backgrounds of the team. We did not have confidence that we could make safe assumptions, or ultimately provide helpful information on this front. Concurrent, we received skepticism from seedling growing experts at the Rodale Institute towards the idea of only heating soil for seedling development. Additionally information gathered from Eliot Coleman’s Four Season Harvest and the 2012 Greenhouse Tunnel Conference show the significant losses in productivity during cold temperature gardening and seed-starting. Coupled with this information, we had enough reason to pursue engineering solutions to heating the entire volume surrounding seedlings, by applying heat not to the soil, but to the air.

With the complete heat loss analysis model back on board, we were able to identify variables that were most influential on heat losses for an air-heated greenhouse. We found that the variables that affect heat requirements are associated with the flux of energy across the film of the greenhouse, the volumetric flow rate of air associated with refreshing greenhouse temperature, and the heat losses along the perimeter of the greenhouse. The flux across the film was the most significant contributor to heat losses and contained within this variable are three more variables: the conductivity of the film, the difference in temperature across the film (that is the constantly held internal temperature and the environmental conditions outside of the greenhouse) and the surface area of the film itself. Initially, the size and therefore surface area of the greenhouse was predetermined, but within our newfound scenario, we began to question whether the heated portion the greenhouse needed to be 30 feet x 96 feet.

Twice Tempered Climate Technology

Additional communications with Chris Callahan, the Rodale Institute and from Eliot Coleman’s book illustrated that an unheated hoophouse could effectively grow crops in Pennsylvania year round. The local Rodale Institute asserts that certain vegetables can grow year round without protection whatsoever.  So we devised an effective solution motivated by Eliot Coleman’s concept of twice tempered climate, in which season extension technologies are utilized within an unheated hoophouse. This way, we could better apply heat only as needed. This idea is contingent upon Eliot Coleman’s findings that a hoophouse will add 15˚F above environmental conditions. He suggests utilizing cold frames inside of hoophouses in order to increase temperatures. By utilizing a smaller sealed structure completely within the elevated temperature environment of a hoophouse, a multitude of heat losses are curbed. Firstly, the flux goes down thanks to smaller surface area, and decreased temperature difference across the film. Second, the volume flow rate of fresh air circulation decreases. Thirdly, the perimeter will be smaller. We ran tests using an 18’ x 18’ x 6’ structure inside of the 30’ x 96’ greenhouse and found heat losses decreased by 7-8 times that of maintaining the temperature of the entire 30’ x 96’ greenhouse. We acknowledge that a variety of other options could further reduce this heat load such as perhaps a number of 1-meter cubes of completely controlled environments, somewhat resembling cold frames. In any case, we think that the usage of the twice tempered climate would be worth considering for LaFarm given the opportunities for flexible climate controls, and low heat costs.

So we devised an effective solution motivated by Eliot Coleman’s concept of twice tempered climate, in which season extension technologies are utilized within an unheated hoophouse. This way, we could better apply heat only as needed. This idea is contingent upon Eliot Coleman’s findings that a hoophouse will add 15˚F above environmental conditions. He suggests utilizing cold frames inside of hoophouses in order to increase temperatures. By utilizing a smaller sealed structure completely within the elevated temperature environment of a hoophouse, a multitude of heat losses are curbed. Firstly, the flux goes down thanks to smaller surface area, and decreased temperature difference across the film. Second, the volume flow rate of fresh air circulation decreases. Thirdly, the perimeter will be smaller. We ran tests using an 18’ x 18’ x 6’ structure inside of the 30’ x 96’ greenhouse and found heat losses decreased by 7-8 times that of maintaining the temperature of the entire 30’ x 96’ greenhouse. We acknowledge that a variety of other options could further reduce this heat load such as perhaps a number of 1-meter cubes of completely controlled environments, somewhat resembling cold frames. In any case, we think that the usage of the twice tempered climate would be worth considering for LaFarm given the opportunities for flexible climate controls, and low heat costs.

Off-Grid Heating

Initially, the idea of creating an off-grid greenhouse was held with somewhat high regard at LaFarm, so it was included as an evaluative criterion. As our research developed, it became clear that an off-grid greenhouse is not so a requirement from a practical, technical, or social perspective. Professor Brandes interjected that the main reason for being off-grid at the farm location was because of the practicality of supplying energy to the LaFarm’s semi-remote location. There are no power lines within close proximity to the field so it was sensible to be off-grid. In contrast, the greenhouse is located in an area closeby to the electric grid, and will soon be closer after a rerouting of a road near the greenhouse site. As he pointed out, the farmhouse adjacent to the greenhouse site is on-grid, so LaFarm in its entirety is not off grid in the first place. From a technical standpoint, off-grid energy supply must be designed around short-term energy usage whereas on-grid energy supply is based on annual energy use. Short-term energy usage must be designed around dramatic spikes thanks to periods of low energy production and high energy use. Our models used worst case scenario conditions in which a greenhouse must be heated for a long cold snap during the coldest time of the year coupled with low photovoltaic and wind production. Overall, we found that due to the unpredictable nature of the supply and demand of off grid energy, an order of magnitude higher number of heat would end up being produced to reliably find heating. In comparison to being tied to the electrical grid, where we can utilize net-metering methods, off-grid heating using intermittent alternative energies is not an attractive option.

Other Methods:

Through investigating specific heat loss scenarios, we came across a variety of other methods for providing heat and electricity to LaFarm.

The traditional technique is to buy electricity from the electrical grid, and to create heat using a natural gas furnace. This technique would be very feasible for heating a large gothic greenhouse, but would be far from carbon-neutral, and would likely be beyond the scope of the needs for the LaFarm greenhouse. An alternative to this option is to use wood burners for heat supply as recommended by Chris Callahan and Vern Grubinger’s research. They feel that while burning wood is not necessarily carbon neutral, it does reduce dependence on fossil fuels. Monica Wentz pointed out that setting up a net metering system can be a significant headache in Pennsylvania, but that tying to the electrical grid, purchasing clean electricity, and utilizing an electric heat pump, a carbon neutral option could be developed. This would need to undergo social, political, and economic considerations as well. The previous greenhouse capstone drew attention to the idea of geothermal heating. Our initial reaction is that geothermal could be a viable option, but due to time constraints, we did not have time to investigate the effectiveness of geothermal heating in the context of our greenhouse specifically.

Some less popular and unproven methods exist for heating that could be both off-grid and carbon neutral. There have been some attempts to utilize heat exchangers from both the heat given off from the chemical reaction in compost piles and from the heat absorbed from sunlight that could be stored in water barrels along the north wall of the greenhouse. Both concepts are widely recognized, but there is little concrete research to validate the reliability of these systems, which are primarily useful based on skilled installation techniques and a strong familiarity with understanding the behavior of composting bacteria and water heat absorption. In order to be implemented, it would make sense to first install a temporary system with cheap and reliable qualities before testing these solutions as part of engineering projects in the future.

Conclusion:

Although we did not specifically analyze technologies that apply heat directly to the soil, we were able to lay out a framework for understanding where LaFarm should go in the future. The most important step for understanding the type of heating and electricity technology at LaFarm will be to define internal temperature based on plants expected to be grown, external temperature based on time of year plants are to be grown, and area for plants that requires heating. After these variables are decided, the type of technology can be chosen. Regardless, we feel that the end result will likely be a stepped solution of implementing technologies over time, including twice-tempered climate technology utilization in all designs. Our calculations support the conclusions of the previous capstone showing that around 25 solar panels could potentially be used to supply the entirety of the power to LaFarm if grid-tied energy solutions are utilized. Nevertheless, we feel that there are a number of other options available that would be equally or more feasible to implement.