Technological Problem

At first glance, there is a straightforward technical problem: to fertilize The ~1.5 acres behind the Newlins Farmhouse in part of the proposed LaFarm expansion area (LaFarm 2015). In order to convert this land from conventional soy and corn farmland, we need to infuse it with nutrients. Technologically speaking, there are many different methods that can be implemented to meet this basic goal of re-fertilizing the LaFarm expansion area. However, as Engineering Studies Students we aim to develop a plan that meets the goal technologically while keeping with the ideals of LaFarm.

Beginning with conventional and moving to alternative methods, we will start by looking at fertilization methods. Although the conventional practices do not fit within the ideals of LaFarm it is still important for us to look at the technical benefits, if any, these offer. After analyzing the technical aspects of conventional methods we have built upon the research done by the 2016 EVST Capstone, on chickens being used as an alternative fertilization method. Following the fertilization method analysis we will analyze the technological aspect associated with the chicken tractor. Using research done by Worcester Polytechnic Institute and information from Sarah Edmonds, the LaFam manager, we go into detail about the different coop possibilities for LaFarm. We also touch upon the additional technology that can be implemented to improve the life of the chickens and lessen the labor burden on Sarah Edmonds. Finally, we have developed a Chicken Tractor Design Program for future groups to use to best determine a coop that will be suitable for LaFarm to implement. This program takes into account all technical factors associated with the coop and also provides the group with an economic analysis based on the select technology.

Conventional Fertilization

One solution for LaFarm’s nutrient deficient soil is to buy and add fertilizers from an outside source to the soil. LaFarm is nitrogen deficient due to the nature of the previous farming of corn and soy. Nutrient deficient soil isn’t a problem that is unique to LaFarm, many farmers deal with similar issues every year. In order to regain the nitrogen levels in the soil, nitrogen rich fertilizers must be introduced. Conventional fertilization methods require the spreading of nutrient rich materials to enhance the soil. The Haber-Bosch is the method used to produce this type of fertilizer. This process is energy intensive and relies on the use of fossil fuels.

We are confident that conventional fertilizers will be able to fertilize the LaFarm Expansion. However, conventional fertilization methods are not consistent with the ideals of LaFarm.

Alternative Fertilization Method

In an attempt to uphold the values of LaFarm and to continue to expand upon the work done be the EVST 400 Capstone, we are proposing the introduction of a chicken tractor to act as a natural and sustainable fertilization method as LaFarm expands.

Chicken manure is the most nutrient rich manure of all farm animals, making this an optimal choice for LaFarm’s fertilization needs. Chicken manure in particular is very high in nitrogen, phosphorus and potassium. Nitrogen is an essential element for photosynthesis and other plant functions. Using manure compost for chickens can cut daily operating costs by replacing organic fertilizers.

A study conducted by Dikinya and Mufwanzala in 2010 found that chicken fertilize had the ability to increase soil fertility and productivity. Adding chicken manure to soil increased nitrogen levels by 50% and phosphorus levels by up to 80%. The chicken manure also increased the yield of spinach that was being grown in the study, proving its fertilizing capabilities (Dikinya & Mufwanzala, 2010). On average, one hen will produce 1 cubic foot of manure every 6 months, providing more than enough manure with 25+ chickens (Dikinya & Mufwanzala, 2010).

Chicken waste can help keep LaFarm sustainable and affordable while assisting an ecologically sound expansion into the Nutrient Enhancement Area.

We propose a Nutrient Center concept where the chicken coop and operations will reside behind the Newlins Farmhouse. According to the most recent plans, the new compost facility will be to the south (left on picture) of the Newlins Farmhouse.

The Tractor

Originally we had planned to design a solar-powered chicken tractor, however, Sarah Edmonds, suggested it may not be necessary to have a solar-powered engine pull the tractor. Nonetheless, solar energy may be better utilized in powering the peripheral energy needs of the chicken tractor (such as a heating pad, an automatic door, or an automated feeding system). In this section, we do not want to establish a set ready to build design, Rather we aim to explore various types of designs and amenities; the ultimate selection will depend on interest from LaFarm volunteers and the College itself. In keeping with the study done in 2016 by members of the EVST 400 class, we are looking at options for a flock that is made up of around twenty five chickens.

Through our research, we have identified three designs for mobile chicken coops that will best suit the needs of LaFarm, each with their own benefits and drawbacks.

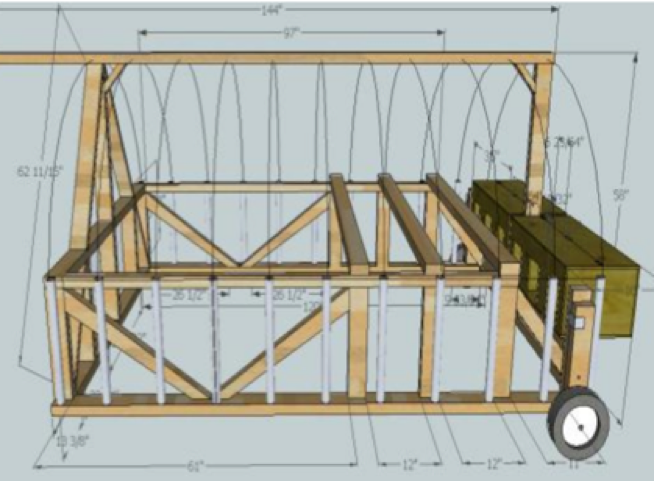

The first type is called a hoop coop as seen below in Figure 1. It consists of a wooden bases and aluminum poles to make the arched roof (i.e., the hoop). The specific design that we found is for a 10’ x 6’ x 4.5’ mobile coop with six 1’ x 1’ x 16” egg boxes, two retractable plastic wheels, a handle for maneuvering the coop, three roosts, and two doors. The benefits include the height of the coop (which is more comfortable for the chickens, the retractable wheels (allowing the coop to lay flush to the ground), and the scalability of the design. However, the height could make it difficult to maneuver and the weight could cause too much stress on the two wheels and cause mobility problems.

Figure 1: Hoop Coop

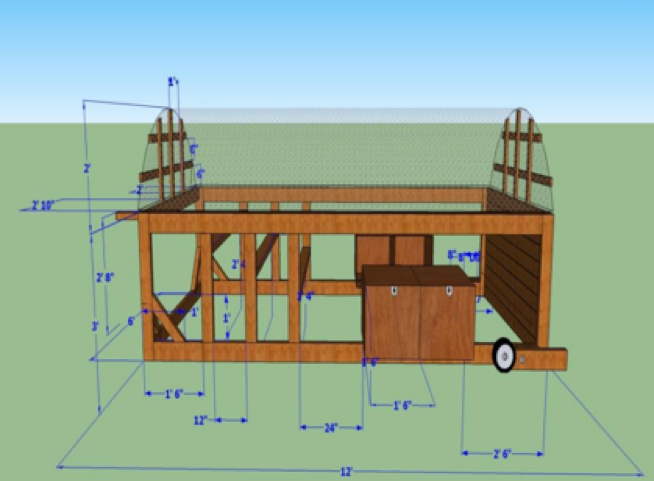

The second type of mobile chicken coop that has been identified is the Salatin-hoop hybrid. This design offers the benefits of a hoop coop with the added stability and structure of a standard coop. It is 12’ x 6’ x 5’ with four 1’6” x 1’6” x 2’ egg boxes. It also feature retractable wheels, a front handle, three roosts, one door, and and a hoop, as seen below in figure 2,. The benefits of this design are its staggered roosts, one fully enclosed side (which protects from strong wind gusts), and the retractable wheels. The drawbacks are the open hoop design (a tarp would have to be utilized in case of rain, if not covered the chickens could drown), the small door, and the added weight of the fully enclosed side.

Figure 2: Hybrid Coop

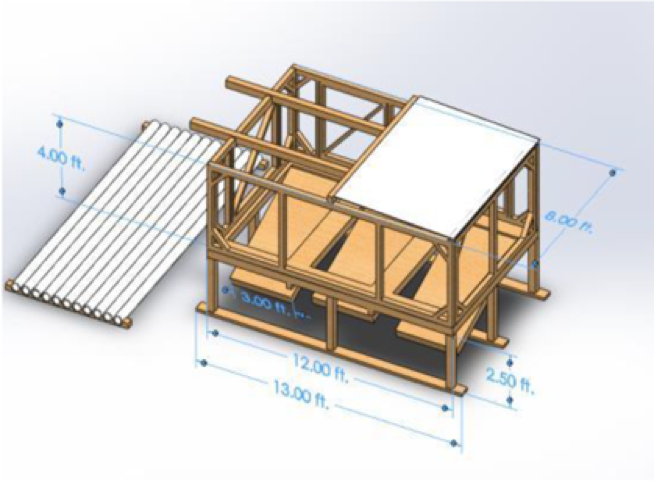

The third design is a fully enclosed coop that is designed to be contained within a second movable pen. As seen below in figure 3, the pen protects the chickens during the day, and the enclosed coop (12’ x 8’ x 4’ with five 1’ x 1’ x 15” egg boxes)protects them during the night. Benefits include the solid flooring of the coop, as well as a smaller size requirement due to the wide range of the outer pen. Drawbacks include the weight and cost of the solid flooring and the increased oversight (chicken owners need to be available to close the doors at night). Sarah Edmonds has worked with a similar design before, and experienced an issue with a predator who pulled the chickens’ heads through the outer pen. This was solved by adding another layer of outer fencing which prevents the chickens from exposing their heads to the world outside of their pen.

Figure 3: Fully Enclosed Coop

Lastly, we also looked into a premade coop. This off-the-shelf model, meets much of the criteria technically. It is safe, has a solid floor, and chicken tested and approved. However, this method is harder to customize with some of our proposed additional technologies. It also does not entirely stick to the ideals of LaFarm. It is still important for the next group to consider this option because of the ease of installation, but be cognizant of the LaFarm ideals.

Figure 4: Premade Coop

Additional Technology

While these designs do not include considerations for solar power, they are good starting points for future groups. Based off of several factors, we believe the third design may be the most feasible for LaFarm. Sarah Edmonds has experience with this design, and the extra layer of protection will help to keep chickens (some of whom may be named by “sponsors,” see Social Context section) safe. The need for a larger amount of oversight than the other options can be rectified through the installation of an automatic door; one brand that manufactures these doors is Poultry Butler (which Edmonds also has experience using). Chickens naturally move into the coop at night; the Poultry Butler operates on a light sensor and provides a timer as well. The website also provides basic instructions on installing a five-watt solar panel, which they claim is sufficient to power the door. Alternatively, an automatic chicken door could be an excellent mechanical engineering project; realistically, however, the purchase and installation of a Poultry Butler (Figure 5) and solar panel array (Figure 6) is the best choice to have the tractor ready in a timely manner.

Figure 5: Poultry Butler Figure 6: Solar Array

Initially, there were strong concerns about the safety of the chickens; Sarah Edmonds assured us that losing a few chickens is just part of the experience, and while important, should not be the main focus of the project. Nonetheless, the chickens should be kept as safe as possible. One of the suggestions that Edmonds offered, in addition to the Poultry Butler, is the option of having a LaFarm dog. This dog could live at LaFarm and would require a fairly low amount of oversight, and could potentially become a sort of mascot. However, if the outer pen/enclosed coop option is the final choice, the dog may not be necessary to protecting the chickens.

Chickens also lay based on daylight; a well-designed chicken tractor should have a light installed inside the coop to account for short winter days. There are many solar powered hanging lamps on the market for rather low prices and they would be quite easy to install in any coop.

There are additional technical elements that must be taken under consideration if LaFarm raises chick, however we recommend foregoing chicks and buying pullets (adolescent chickens) to avoid the unnecessary hassle of raising baby chickens.

Chicken Tractor Design Program

To compile all of our technical factors for the next group, we used an Excel sheet loaded with macros to allow maximum customization of the users preferred tractor system. This program allows the user to choose from any of the four coop designs and add whichever features they believe to be necessary. Additionally, when the user finishes their design, it will produce an image of the tractor which was designed in AutoCad, and will populate the tractor with the chosen features. The AutoCad drawings in figures 1, 2, and 3 were designed to scale, using the dimensions from the dissertation (Cole, DeLuca, and Zielinski, 2014) and the website from which the pre-made coop can be ordered from(Houzz.com). Additionally, the materials needed to construct each of the coops is listed on a separate materials page on the Excel file.

Conclusion

The technical analysis looked into the fertilization potential of both conventional and alternative methods. After confirming chickens as a viable solution, we analyzed different coops for their many different benefits and some of the drawbacks. After assessing each of the coop models, we moved on and analyzed some of the potential additional technologies available. Looking back to the identity and needs of LaFarm, we are recommending that the next group implement, at the minimum, the poultry butler powered by the solar array to alleviate some of the burden on both farmer Sarah and any of the LaFarm volunteers. Finally, we have provided a method for the next group to design and build the best chicken tractor for LaFarm to install. Using our Chicken Tractor Designer Program, the next group will be able to see all of the necessary economic costs, materials, and dimensions in order to fully implement the chicken tractor at LaFarm.