Are you ever randomly in the mood for a cheeseburger? I know I am! Oh wait, it’s raining outside, I don’t want to go out there to turn on the barbecue! Lucky for you all out there, we have created the JAM Burgernator to solve all of those problems! This machine is designed to cook your burger, melt some cheese on it, dump on some condiments and toast the bun all while staying indoors! Fascinating! I know right?

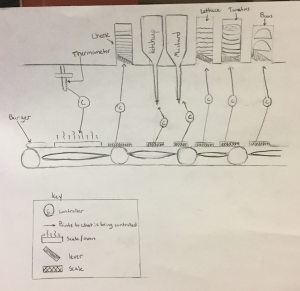

What really happens is that you would put the raw meat on the conveyor belt, where the meat is probably about room temperature or colder. On the machine face you can pick how well you want the burger to be cooked, let’s say you want medium which is about 140 degrees Fahrenheit. You can also choose what type of cheese you want as well as the condiments such as ketchup, mustard, tomatoes, lettuce, relish and barbecue sauce all with ‘small, medium, large’ options to designate how much you want. The meat would slide into the machine where it would travel slowly and then stop at a place where a heated press drops down conveniently with a thermometer inside. Simultaneously, the press will cook the burger as well as ensure that it is the perfect temperature to maximize user satisfaction. Once the burger is cooked, it moves over to where a slice of cheese will land upon it and melt due to the heat of the burger. The next part is where all the condiments will squirt over the cheese, and the lettuce and tomato will gently be placed on top before two perfectly toasted buns complete the wonderful burger.

Normally, to make a perfect burger you would have to shape the raw meat on a plate where blood juice would get everywhere, stain your clothes, and just make a complete mess. Then you would carry the meat plate all outside, rain or shine. It is important to keep track of the time or else the burger will burn and you will also want to go back outside to flip the burger over. Then, later you have to remember to put a slice of cheese on top in enough time so that the burger doesn’t get too well done but also so that the cheese has enough time to melt. Then you would have to time exactly how long the bun needs to be in the toaster, say when the burger has approximately two minutes left, the buns need to go in. To grab the burgers off the grill you would need a clean plate and serving grabbers which means more dishes to clean afterward and then you have to carry all the supplies back inside. This process definitely takes much more time than our machine, and uses many more serving pieces than necessary. On top of all that, you would need to put out on the table all of the condiments and vegetables, but at the right time so that what should be served cold, is still cold and not room temperature. The machine eliminates all of these worries and lets people just sit and relax while the burger is in process.

This machine needs to be controlled to ensure that the meat is cooked properly. It is a safety hazard if a restaurant served uncooked burgers, so it is very important that the temperature is right, although, the temperatures of all types of burgers do fall into a range of 120-160 degrees Fahrenheit. Families would not buy this machine if burgers were not cooked up to their standards and customers would stop going to the restaurants with unsatisfactory burgers as well. As a result, the color of the burger/how well the burger is cooked is the control variable which is based on consumer preference. A person who likes medium rare burgers would be very unhappy if this machine spit out well-done burgers and vice versa. The manipulated variable is therefore the temperature or the heat going in because the temperature of the press manipulates the temperature of the burger but the temperature of the press is determined by the amount going into it. The machine changes the temperature of the burger depending on what the consumer chooses to be their color of meat. As a result, it is designed so that the user puts a slab of meat on the conveyor belt, presses the button for how well they want the burger done, and the machine does the rest. This means that there has to be some communication between the thermometer on the press and the control panel. The thermometer tells the control panel the specific temperature of the meat while the control panel tells the thermometer what temperature the meat should be at. This is a process that goes on and on until the burger is cooked to perfection. This is a feedback loop because the temperature of the meat is measured and then this information travels back to the control panel which is a good set up so that the temperature can change based on the disturbance variables such as if the temperature in the burger is very low going into the machine, the controller makes a decision, and then the amount of heat going into the burger due to the press will increase to compensate.

How often do you go to a restaurant or fast food place and get too much of a given condiment or they put something on your burger that you don’t want? With the JAM Burgernator customer’s preferences of what and how much of a given condiment will be placed onto the burger will be controlled for maximum customer pleasure. On the JAM Burger there will be a button on the machine where you can choose which condiments you want as well as how much you want such as small, medium, large. The machine will be able to tell relative to the size of the burger and how much is really a ‘large’ versus a ‘small’ amount. The control panel will tell the compartment of condiments how much of everything needs to be applied and they will communicate to produce a burger with the correct amount of stuff piled on top. It is important that the ratio is correct so that the burger isn’t too soggy or too dry. The size of the burger also needs to determine the correct portion of condiments that need to go on top. If the burger if very small and a lot of ketchup falls on top, you’re going to have a big mess! It will allow customers to put on extra of certain condiments, and eliminate others. This will also allow industries selling these burgers to save money by not putting on extra condiments that will go to waste, and to be able to control the exact amount that goes onto each burger. In this instance the manipulated variable will vary depending on what condiments are to be placed onto the burger. For solid condiments such as lettuce or tomatoes there is not much control to be done. It will be controlled through a motion sensor that detects where the burger is and that would trigger a lever that would allow a certain number of that specific topping to be placed on top of the burger. The hardest part would be to control liquid condiments such as ketchup or mustard. In order to control this the manipulated variable would have to be the rate at which ketchup or mustard shoots out onto the burger. This would work best with a feedforward loop with a sensor measuring how much of the condiment is coming out. A feedforward loop would work best in this given scenario because it would be very difficult to measure the amount of ketchup that goes onto a burger after the process takes place with a feedback loop. Therefore, in order for this to work the measurement of the flow rate of the liquid condiments coming out has to be carefully measured because the end result is too difficult to measure.

A possible source of disturbance could be the type of meat itself. Some meat may be more dense or need to be cooked different ways in order to be cooked thoroughly such as a turkey burger versus beef. Another source of disturbance could be the size of the meat. If you just throw in a slab of meat the press will still come down and cook the burger, but different sizes could affect the cook time or the meat may spread out past the heat press. It is important that all parts of the burger get cooked the same amount so it needs to be heated evenly. Other sources of disturbance could be if there is a problem with the thermometer. If the thermometer is malfunctioning the entire system will fall apart because the burger would not be cooked well enough, the cheese would not be melted, and the bun probably would not be toasted. Another possible source of disturbance could be the condiments. The size of the burger also needs to determine the correct portion of condiments that need to go on top. Based on these variables, possible problems could be that the machine needs to be refilled with the cheese and condiments and buns. One way to store all of these items in the machine could be having their compartments more like a refrigerator so that everything is cold and fresh. The difficulty with this is that the machine will be very hot because it needs to cook the burger so the compartments will need to be located as far from the heat source as possible to ensure that they are dispensed properly and fresh.

Based on all of these aspects of our fancy burger machine, everyone should want one of these! Have no fear of uncooked meat! Buy the JAM Burgernator!

Personally, I do not think that I would buy this product. That being said, people who often eat burgers or maybe restaurants would be more likely to use your application. I think you did a good job describing how and why one would want to use this product. However, I have trouble seeing how this product makes it easier to make a burger. Checking the temperature to make sure the burger is cooked to perfection is a good idea, but I do not think the other applications (such as adding the condiments, lettuce, and tomato) would be necessary. To apply these by hand is quick and easy, and then the person can put the exact amount they want on the burger. Also, how would the lettuce and tomatoes be stacked on the burger? Would the consumer need to stock the machine beforehand (as this seems like it would only take more time)? Would there be a refrigeration aspect to the machine in order to keep the condiments cold? The need for this product in the market does not seem very prevalent. I think the only way that this product could be feasible would be to feed larger crowds, as it seems like more work to stock the machine and everything in order to feed a family than to cook the burgers on the grill or the stove.

The proposed control scheme made sense. The manipulated variable was the temperature or heat going in, because this would vary based off the customer’s preference for how they want their burger cooked. This process works as a feedback loop, and more heat will be supplied if the desired temperature is lower than it should be. I don’t think the feedforward control for the condiments is necessary. Would it take into account the size of the burger? How does it know what flow rate is necessary to create the perfect ratio of condiment to burger? I think you did a great job describing some of the disturbances, such as the type of meat, the size of the burger, and thermometer malfunctions. How would you address these disturbances? I would suggest maybe putting in the raw meat and having the machine shape the burger, so that they are exactly the same size and thickness, which would be easier to control.

Lastly, based off all of your limitations discussed in the final paragraph, I do not think this application would be usable in actual practice. Maybe you could go more into the logistics, including how the burger is cooked and how it will move along the conveyor belt. Would this just be one singular machine that someone could buy for their home? The cost of this seems like it would be quite high due to the heating and technology. Would people be willing to spend a lot on a product that has only one specific application, making burgers? Manufacturing of this application could become very complicated. I think that you could offer this to a different audience like schools or restaurants. Therefore, the cost would not be as significant, and this technology could be used to more quickly make burgers in bulk when there is high demand.

This application is great! I know when it’s raining, my family has to bring our grill all the way to the front of our house so that we can put it in the garage. Without the JAM Burgernator, it’s too much of a hassle to cook a burger on the stove when a grill just won’t do.

As I understand it, the control scheme is that the controlled variable is the color of the burger and how well the burger is cooked. Because the machine is doing the controlling, I think it would be hard for the machine to determine if the color of the burger is just right, or if the burger is cooked to the specifications. I think a more specific way of defining a controlled variable would be to control the temperature of the burger itself. There could be a setting within the machine in which the user could choose somewhere on the scale of rare to well done, and the machine would know to which temperature that this setting corresponds.

The manipulated variable here is defined as the temperature/heat on the inlet of the machine. I think these are both valid manipulated variables because the temperature/heat going into the machine will directly impact the degree to which the burger is cooked. Another potential manipulated variable could be the cooking time under the heated press because this will directly impact how the burger is cooked.

The disturbance variable that is reported in the article is the temperature of the meat on the conveyer. I think this could be a disturbance in the process, but if the manipulated variables are the temperature/heat and cooking time, the process would easily account for such a disturbance. For these reasons, I’m not sure that the initial temperature of the meat would significantly disturb the process. Another potential disturbance variable that was briefly discussed is the size of the meat being put into the machine. If the meat is too large, then it may not fit under the press where the burger is cooked. If this is the case, then the temperature reading could say that the burger is done cooking, but the edges that were not completely under the press may not be cooked, which is a health hazard. Though this may not be a disturbance variable per say, if the thermometer is only measuring one spot on the burger, say the middle, the entire burger may not be exactly at that temperature. Some of the burger may not be cooked properly if only one temperature measurement is taken, though the process is showing that the burger is fully cooked.

I think this application is quite practical for in-home use, especially on rainy or cold days when you just really want a burger. The question that I have is how large would this machine be? In my kitchen, we have very limited counter and storage space, so I would question the compactness of the system. I think this may be an applicable machine for use in the food industry, but I’m not sure how many burgers could be cooked at a time. A grill can simultaneously cook as many burgers as can fit on the grill, so I think this machine would need to be cheap, cost efficient, and space efficient to really be applicable in the restaurant and fast food industry.

This is a pretty cool application. Everyone loves burgers and having barbecues on rainy days is quite impossible, but with your application, it can be made possible. However, from a practical standpoint, it seems more like a fantasy than a reality to me. I’ll start with the points that I liked and seemed potentially usable to me. I like how you made it pretty easy to envision the machine–at least the outside of it by specifying some of the design specifications like: the conveyor belt, heated press with a thermometer,..etc. It makes sense that you want to control how cooked the burger is, because people like their burgers in different ways. For me personally, I would be bummed if my burger is anything less or more than well cooked. However, I think it’s better if you define your controlled variable as the temperature of the burger. You want to control the temperature that cooks the meat, which in turn affects how well it’s cooked. The manipulative variable is the temperature of the heater or the amount of heat going in, which makes sense, because you play around with the amount of heat transferred to ensure that your burger is cooked as desired. The proposed scheme of a feedback loop sounds logical because you measure the temperature of the raw meat first, and accordingly you decide how much heat you need to provide. I’m not sure if your disturbance variable should be the type of meat. The way I understand disturbance is that it’s a variable that causes noise and can’t be adjusted by the control system. However, different types of meat will require different specifications but won’t cause deviation from a set point, because there isn’t really a set point. Maybe a disturbance variable would be something related to the heater, the motion of the conveyor belt or the duration of response, because no one wants their burger to burn because it is taking the machine forever to squirt out the mustard.

You mentioned a lot that the “machine will tell…” and this was how most of the process was portrayed, but maybe something to look into would be how the machine actually operates. The mode of operation was glossed over by assuming that the machine will just tell this or do that, but we don’t know how exactly. I really like how you made the distinction that when applying condiments like: ketchup and mayo, you would want to have a feed forward loop, because you don’t want the burger to be messed up by extra ketchup that you’ll have to wipe off later, it’s nice to know in advance how much you exactly want. However, this was another thing that wasn’t really clear how it would work. Personally, I hate tomatoes and it grosses me out so much to have to remove them from a sandwich and it pisses me off when I say with my order that I don’t want tomatoes, but it would still come with tomatoes, so your feature of controlling solid condiments as well, spoke to me on a personal level. At the end you mentioned having refrigerated compartments, I think this requires looking into how big your machine would be. Given that heat transfers, this feature might be hard to implement with all the heat you’re inputting to cook the burger. You might also want to talk about the materials used to make the machine, the cost of it and more specifications of the machine itself. As much as I appreciate you going above and beyond with your imagination and creativity, I don’t really think that this is a practical application, because there is quite a few logistics that weren’t touched upon.

I do appreciate the idea of having a machine that can generate a burger based on users’ preference. However, I do not foresee that this application will be popular and useful to the general public and I personally will not buy this product. The idea is novel but I do not understand why this application will make it easier to make a burger.

For the burger-cooking part, the feedback control scheme makes sense and is straightforward. The controlled variable in this case is the temperature of the meat; the manipulated variable is the amount and the temperature of the heat going in. The explaining of possible disturbances, such as type of meat, temperature of the meat going in, the size the meat, etc, makes sense. Also, I think you guys did a good job of explaining the results of possible situations that will happen to the system, such as malfunction of thermometer. However, I have some confusions I want to address. When I was reading the article, I noticed in the article it says ‘The thermometer tells the control panel the specific temperature of the meat while the control panel tells the thermometer what temperature the meat should be at. This is a process that goes on and on until the burger is cooked to perfection’. Since this is a feedback control loop and the temperature of the meat should be compared with a set-point temperature determined by how well the users want their meat to be, shouldn’t the control panel control the heat valve and change the amount of heat going in after being notified of the meat temperature? If the control panel simply just tells the thermometer what the meat temperature is but does not compare it to the set-point temperature and does not control the heat valve, then what is the point of having a feedback control loop? Also, for the thermometer measuring the meat temperature, do you actually have a temperature probe that will stick into the meat or do you just have a thermometer inside the machine? A diagram explaining the temperature control scheme inside the machine would be much helpful.

For condiment-adding part, before expressing my personal thoughts, I have a question I want to bring up. In the article, it says that “The machine will be able to tell relative to the size of the burger and how much is really a ‘large’ versus a ‘small’ amount.” How is the system going to tell the size the burger? Is there a detector-like device installed at the entry of condiment-adding system to give an approximation of the burger size? For the system itself, I personally do not think this application is necessary. For the machine to add condiments and generate a satisfying burger, it has to know the type of and how much condiment the user wants on the burger and size of the burger and it has to control the rate of liquid condiments being shoot out. Indeed, the idea of having an automated condiment-adding system is great but wouldn’t it be much easier to just let the user to add the condiments him/herself? Building a system that has a motion sensor to detect where the burger is and levers to add condiments onto the burger would require a lot of money. This condiment-adding system will not bring ease and convenience but it will require substantial amount of work and large number of parts to build due to its complexity and, thus, large amount of money.

Personally, I do not foresee this application being useful in actual practice. One of the most important limitations is cost. Building a such complicated system would require lots of money to build. Another limitation is the space. If we were to implement a condiment-adding system onto the machine, it will take a substantial amount of space. I do not think that it will be practical to buy such an expensive and large machine for just in-house usage. The machine is more suitable for food industry. Also, it would be a waste if we let this complicated machine to generate just burgers. Since the machine has an infrastructure that can monitor the food temperature and cook the food based on what the user desire, we can use the machine to barbeque some other foods.

The idea to create a machine that makes the perfect burger is very unique and interesting, however, I do not think that it is very practical. While I understand that people may not want to grill in the rain or clean lots of dishes after a barbeque, I think that the JAM Burgernator complicates the process of making a burger and would not be cost effective. From what I can tell, the machine also only makes one burger at a time. If being used for a party or family dinner, would everyone have to wait for their burger one by one? In my opinion, it is not that difficult to cook a burger on the stove in the event of rain and it is not a hassle to put your own condiments on the burger. Therefore, I do not foresee a machine such as the JAM Burgernator having a big market and I do not think that I would use this type of machine.

This being said, I think that the proposed control scheme for the machine makes sense. The controlled variable was determined to be the color of the burger/how well the burger is cooked. I think this is a difficult way to define the controlled variable and an easier way to measure how well the burger is cooked is through the measure of internal temperature. The feedback loop is set up through the use of the temperature of the burger so while the blog article articulates that the color is the controlled variable, I believe the intended controlled variable is the temperature inside of the meat. The manipulated variable is defined as the heat going in to the burger, which makes sense for this control scheme. If the burger is not cooked enough and the internal temperature is not at the desired level, the feedback loop would add more heat to cook the burger. The disturbance variables considered are all viable concerns for this machine however, there were not many solutions presented. For example, if the controlled variable is the internal temperature, a setting could be incorporated to inform the machine on the type of meat. Therefore the set point could be adjusted to the correct temperature for that specific type of meat to be considered thoroughly cooked. One solution to the size of the meat would be to have the machine shape all of the burgers to ensure even cooking. The control scheme for the condiments also makes sense. For the liquid condiments, I like the use of the feedforward control system because once the ketchup or mustard is on the burger, it might be too late to adjust the amount.

In order to make the machine a more realistic application, I would eliminate some of the features. While I do not see a market for the entire machine, I believe that the control scheme to cook the burger could have a very real application in the kitchen and would be very useful. My mom constantly worries about cooking meat thoroughly enough so that we do not get sick from eating uncooked food. In this situation, the first half of the machine could have a major role. If there was a system measuring the internal temperature and relaying the information back to ensure the burger was cooked to perfection, it would eliminate the worries of eating uncooked meat. The portion of the machine that adds condiments seems like an expensive and unnecessary addition. Small, medium, and large are general terms and would not be as accurate as the user adding how much of a condiment they want. Therefore, in order to make this product more viable, I would suggest removing the condiment portion and focusing on cooking the burger.

Personally, I doubt that I would purchase this product. While I do enjoy the occasional burger, especially with a large amount of bacon, I don’t think this would be a regularly used appliance in my home kitchen. That said, I could see this being a popular specialty item for your local burger fanatic. I believe that some restaurants would also purchase this product and benefit from its consistency and efficiency.

The proposed control variable in this application is the color and doneness of the burger being made. As someone who enjoys cooking, I take slight issue with this proposal. Firstly, the color of meat will be different depending on several variables. The fat content of the meat used, as well as where on the animal the meat came from will affect the color of the burger as it cooks. Additional considerations when it comes to color should be that burgers can be made from many different foods, including beef, turkey, chicken, bison, and even vegetables. By controlling based on color sensing, the consumer is limited to beef burgers from one cut, of only one fat content. My second issue with the proposed control system is the temperature measurement. If the burger’s temperature is measured using only a sensor on the press, then only the outside of the burger will be temperature controlled. Since the temperature of the outside of the burger will, obviously, be higher than the temperature of the inside, there cannot be control of the actual doneness of the burger without temperature measurements of the inside. I would suggest the incorporation of a probe thermometer, rather than just a thermometer on the cooking press.

The manipulated variable makes good sense. Changing the amount of heat entering the meat according to its current temperature and the amount there is allows for good control over how well done the burger becomes. Another variable to be considered would be the cooking time of the burger, dictated by the speed of the conveyer belt it is travelling on.

The proposed disturbance variables in this application are the amount and temperature of meat being put into the burgernator. I think that these both make sense. However, I would personally like to see the amount put into the machine regulated as well. To me, the product is all about consistency and quality. If you are able to put in as much meat as you want, it will prevent consistency of burger size. I’m not sure how you would want to go about this, but I think control over the amount of meat input would be a good addition.

I could see this machine being used by fast food establishments, as well as some lower-level chain restaurants. Think along the lines of McDonalds and Burger King as well as Applebee’s and Fridays. However, I doubt that higher end restaurants would want this product, since it would strip them of creativity and individuality. The individual consumer may also appreciate the product, depending on just how much they love burgers.