Technical Context

Introduction

The technical focus of this project examined how to use renewable technologies to take a greenhouse off the grid for Lafarm, while also providing all the necessary energy needed to properly run the greenhouse. Our research builds off of techniques employed by numerous farmers to improve the efficiency of the greenhouse. In this section we analyze some of these techniques in order to find an efficient and successful way to accomplish our goal of an off-the-grid greenhouse.

Layout and design elements

In order to fulfill the needs of Farmer Lisa Miskelly, the greenhouse will need to be twenty-four by fifty-eight feet (Miskelly 2019). These calculations include space not only for LaFarm, but also other community partners. They also assume that LaFarm will eventually produce more than two times its current capacity. what it is already producing. Although these dimensions differ from previous capstone reports, this size allows for enough benches to help our community partners as well as allow LaFarm to expand. The greenhouse is expected to be located next to the Lafarm out at the Metzger complex (see figure 4). This placement will be at the bottom of a hill, which raises concerns about flooding because of downhill drainage. Due to a lack of geotechnical analysis for this location, we are unsure if this location is the most suitable. Before construction begins, it would be beneficial to have civil engineering students do a detailed geotechnical analysis to ensure that this plot of land is suitable for the greenhouse. The significant benefit of this location is that it is very accessible for Lafarm workers. They can easily get the seedlings from the greenhouse and transport them to the main farm in spring.

Figure 4. Proposed Location of Greenhouse. Google Maps

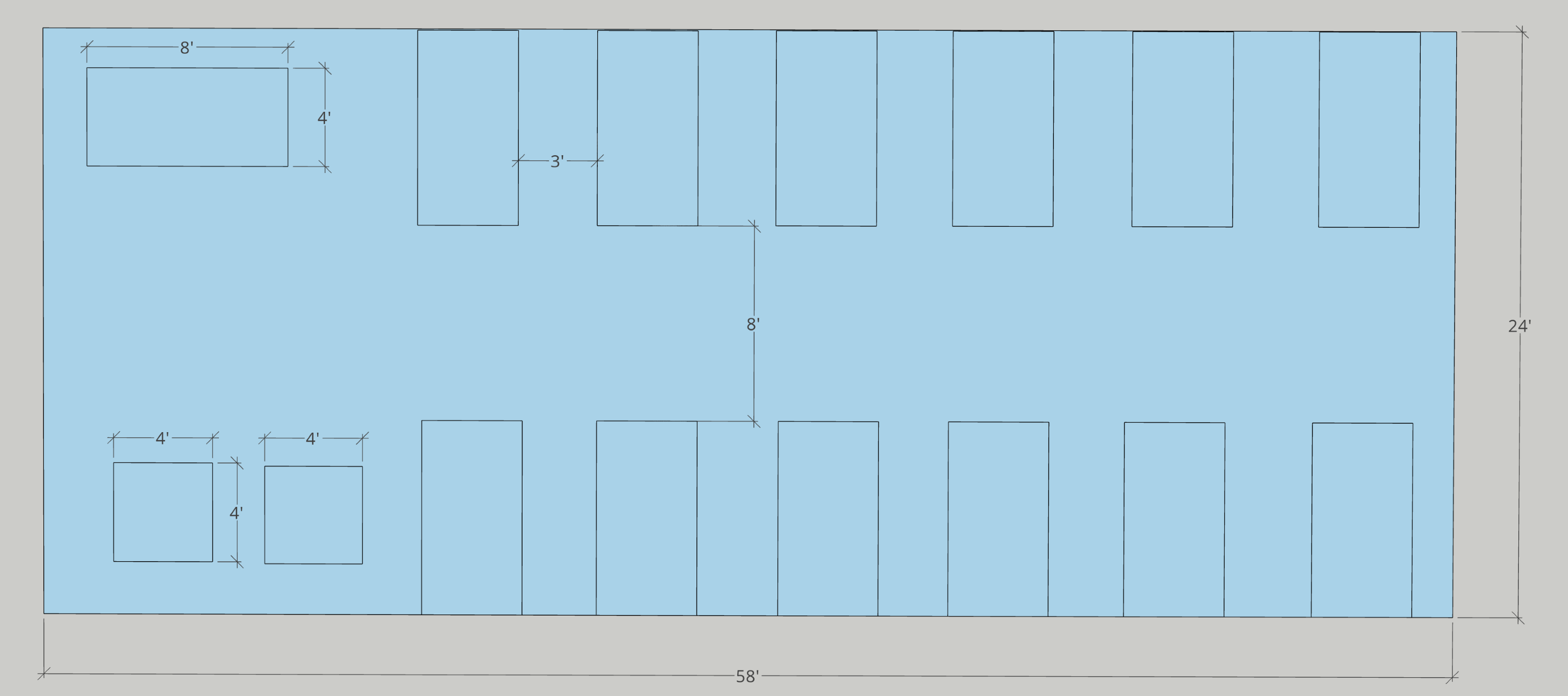

The proposed floor plan of the greenhouse not only allows space for plants, but is also a work space for students and Farmer Miskelly to prepare and maintain the trays of seedlings (figure 4). At the entrance, there is a space that will include a 4 by 4-foot bin for potting soil and a 4 by 4-foot area for preparing seedling flats. On the other side of this space there will be a 4 by 8-foot table work bench meant to provide a general space to complete tasks such as simple repairs and maintenance or data collection. The rest of the greenhouse will be filled with twelve benches. Each bench will be 4 by 8 feet and can hold 22 seedling trays. With this consideration, Lafayette will have 6 tables, 3 for current needs and 3 for expansion. Crayola will need one table for their small community farm. Easton Urban farmers will require two tables and Easton community gardens will require 2 tables as well to fulfill their goals. There will be a three-foot walkway between the benches, which will accommodate for inexperienced volunteers because it gives them plenty of space to maneuver with equipment between the benches . These benches will also be on wheels, which will help Ms. Miskelly be able to efficiently move the plants around the greenhouse.

Figure 5. Floor Plan. Created by Authors.

Our greenhouse plans incorperate a couple design elements that are modeled after Liberty Farms greenhouses in Coopersburg, PA owned by Jeffery Frank. We plan to install a root heating system that uses a water heater and water pump to pump hot water through hoses that will be placed under the seedling flats, as shown in figure 5.

Figure 6. Heated water hoses under trays. Photo by authors.

This system works because seedlings only need their root system to be at the proper germination temperature. The air temperature could be much cooler, but as long as the root systems stays warm, then the seedlings will still grow (Frank 2019). The temperature of the water will heat the roots up to a range of 70 to 90 degrees Fahrenheit because this is the optimal range of germination as seen in figure 6 (Joseph Kemble 2019) The system’s efficiency eliminates the need for heating matts and space heaters, which are both somewhat inefficient (Frank 2019). This system is not only very efficient, but it is also quite simplistic. With only a pump, hoses and water heater, the system is rather easy to care for, which is very beneficial to Farmer Miskelly.

Figure 7. Soil Temperature Conditions for Vegetable Seed Germination. Joseph Kemble (Alabama A&M and Auburn Universities).

In order to ensure the efficiency of the root heating system, we also recommend seeking assistance from mechanical engineers to do a heat transfer and fluids study on the system. This study will yield data about energy consumption changes as temperature changes. The colder the temperature gets, the more quickly the water leaving the hot water heater gets cold (Frank 2019). If the system does not adjust, then the root systems could get too cold and the seedlings would be negatively impacted.

In greenhouses, air mass is an important barrier that helps keep the plants from experiencing cold winter temperatures (Frank 2019). One way to add to the air barrier is to form the wall of the greenhouse with two sheets of plastic (Frank 2019). Then using spacers, a gap between the two sheets is created which adds this barrier. This is a simple way to further protect the seedlings, without having to expend energy. This air acts as a buffer between the cold outside and the temperature of the plants (Frank 2019). This barrier also adds to the durability of the greenhouse in general. By having two layers, a tear or puncture in the outer layer would not compromise the seedlings inside. In both cases this barrier helps protect the seedlings from the cold and inclement weather outside the greenhouse.

Ventilation is critical to pest control and temperature regulation. In spring and summer, the temperature in the greenhouse can become nearly unbearable. To account for this, our design would include outer layers have the capability to roll up. This will allow the greenhouse to breath if necessary and will help move air through the space and keep the space from being too uncomfortable to work in (Miskelly 2019).

Geothermal Analysis

After reviewing the previous three capstones, two brought up the potential of a geothermal heating system, but neither of them analyzed geothermal in depth. There are two geothermal techniques that are most prominent in residential and greenhouse construction; sinking the greenhouse and a geothermal heat pump. Both options take advantage of the constant temperature that exists just four to six feet below the surface of the earth (DOE). The geothermal component would provide a stable base temperature. One of the huge advantages to geothermal is the consistency of the heat because it is not dependent on weather. For example, while a solar panel relies on sunlight and a wind turbine relies on wind, geothermal has its constant source of heat.

Sinking the greenhouse is a geothermal technique in which the greenhouse plot is excavated by about five to six feet to get below the frost line. The seedling are then grown below ground level. In our case we would be excavating the 24 by 58 plot and then the benches would sit below the surface of the ground. In order to add to the stability of this structure, we would need to line the excavated section with concrete bricks in order to keep the walls of soil in place for a long period of time. Once the excavation is complete, we would then proceed to build the greenhouse above the excavated plot (Figure 7). The entrance to the greenhouse would have to be a set of stairs leading down in the space five feet below the ground. In the end, this technique lowers the entire greenhouse into the ground.

Figure 8. Sinking the Greenhouse. Insteading.com.

This geothermal technique thankfully does not rely on technology that could be prone to breaking, unlike more complex geothermal systems. Complex geothermal heat pumps are very difficult and expensive to repair, so this technique has a benefit over more complicated systems. The lack of technology not only simplifies the design, but also decreases the amount of electricity needed to run the greenhouse. The simplicity of this design will significantly limit any extra maintenance other than what is normally required for a greenhouse.

While there are some positives to this simplistic design, there are some immediate concerns. The most important concern is flooding of the greenhouse. In the last year, the Lehigh Valley has seen record breaking rains this year (Sigafoos 2019). With this design being below ground, we run the risk of having destructive flooding. This would require our design to include a waterproof liner that will line the entire floor and subterranean walls so that in the case of heavy rains, flooding will not affect the plants or the structure. One option would be to place a strong plastic liner that would cover the plot (Stock 2014). Given the size of the greenhouse though, it would make more sense to apply a polyurethane sealant onto the concrete bricks that would harden to create an impervious membrane between the soil and the concrete wall (Stock, 2014). The structure would also require the addition of a drain tile (see figure 8). This will divert the water away from the structure. While sinking the greenhouse certainly will end up with a more simplistic design, subterranean construction is very complicated, particularly when it comes to flooding prevention. Also sinking the greenhouse will only provide a constant temperature of 50 to 60 degrees Fahrenheit. These temperatures are not in the optimum temperature range for germination, which means that we would have to supplement temperature control with heat mats to bring the temperature up to that optimal range. So, the final project will end up being much more complicated than initially anticipated. Thus, we don’t recommend the option of ‘sinking the greenhouse’ for the carbon neutral greenhouse.

Figure 9. Drain Tile. Zablocki Waterproofing.

The second geothermal technique we considered was a geothermal heat pump. A geothermal heat pump also takes advantage of the stable temperatures under the frost line and is made up of pipes or tubes put into the ground about six to seven feet deep (Department of Energy 2019). These pumps have water with antifreeze inside of them that gets pumped through a heat exchanger to transfer the stable temperature into an air duct system (figure 9). Once the temperature is transferred through the heat exchanger, then the air ducts will deliver the stable temperature to the greenhouse. Due to the technical aspects of this work, this solution would require us to contract out the work with a special contractor who is familiar with this work. This would require additional research on contractors in order to select one that is experienced but also of value so that the system will last a longtime while not being overly expensive.

Figure 10. Geothermal Heat Pump. Sinton Heating and Cooling.

There are some positives to having a geothermal heat pump. First, the main benefit of having geothermal is that the heat would be coming from the constant temperature below the frost line, so there isn’t a very significant reliance on electricity to power this system. Compared to sinking of the greenhouse, we would not have to be so concerned with any flooding because our greenhouse would still be above the ground.

While this system could be effective in heating the greenhouse, there are some negative aspects to this system. The most significant drawback is the reliance on some energy source to keep the system running and pumping fluid. To pump the fluid, the heat pump would use about 24 kWh per day. While this is a small amount of energy, it is still a demand for electricity. The heat pump will be connected to either a solar or wind system and this will add to energy demands made on the source of electricity. Another concern about this system will be the potential for breaks or leaks in the piping. While it is unlikely that the system will break (DOE 2019), when it does, it is hard to find the source of the problem and usually the entire system has to be excavated, which would not only be incredibly expensive, but it would also put the greenhouse out of commission for a significant amount of time.

While geothermal is compelling and is very efficient in stabilizing the temperature, we would have to heat the greenhouse further in order to reach a temperature of 70 to 90 degrees to optimize germination and seedling growth. By adopting Mr. Frank’s technique of heating the root system we can heat the plants efficiently by expending as little energy as possible. Only heating the root system makes a solar energy system potentially possible because of the small area that needs heat.

Solar

The most common way to harness solar energy is through the use of photovoltaic panels. These panels capture the sunlight and convert it to electricity. This conversion happens at the atomic level when the photons are absorbed onto a photoelectric material that then takes the free electrons to form an electrical current (NASA 2008). In the case of the greenhouse this electrical current would power vents, fans, water heater, and run the irrigation, as well as power the thermostat. The benefit of these solar cells is that they are very simple and rather straightforward to use.

In order to understand how many solar panels would need to be installed, we first estimated the energy usage of all the systems in the greenhouse that will require electricity. This is reflected in the following table.

| System | Watt | Hours/Day | Days/ Year | Energy/Day (kWh) | Energy/Month (kWH) | Energy/Year (kWh) |

| Fans | 115 x 2 | 22 | 160 | 5.06 | 152 | 810 |

| Vents | 621 x 4 | 12 | 90 | 29.8 | 894 | 4768

|

| Irrigation | 11 x 24 | 3 | 160 | 0.792 | 24 | 127 |

| Water Heater | 4500 | 24 | 90 | 108 | 3240 | 9720 |

| Water Pump | 725 | 24 | 90 | 17.4

|

720

|

1566 |

| Total | 8203 | 161.05 | 5,030 | 16,991 |

Figure 10. Energy Estimations. Created by Authors. Data from DOE.

Based our these energy estimates, we calculated the solar array would need to be approximately 656 square feet, which is the equivalent of about 37 solar panels. This calculation was based on the factor that a 5kw system translates approximately to a 400 square feet (EnergySage 2019). Then based on the average size of a solar panel, 5.45 feet by 3.25 feet, we were able to approximate that 37 panels would be needed (EnergySage 2019).

Though there are concerns about a solar based electrical system, we have considered potential solutions. The most prominent concern is whether or not there will consistently be enough sun to power the greenhouse. Based on data from the national climatic data center, there are about 4.5 hours of peak sunlight per day, however during the winter the cloudy weather may bring that average down making solar production sub optimal (EnergySage 2019).

One option would be to include solar power batteries that can store energy from days when sunlight is plentiful. We want to install a solar storage battery that had a high capacity as well as moderate power rating. The capacity refers to exactly how much energy can be stored, while power rating dictates how much energy can flow when the system taps into the reserves in the battery (EnergySage 2019). There are two types of batteries; lead acid battery or lithium ion. The lithium battery lasts longer but is more expensive than the lead acid battery. However, the lithium battery tends to have a higher depth of discharge, which means that you can run the battery down further before it needs to be recharged (EnergySage 2019). While both are good options our group decided to choose a lithium ion battery as the back-up because it has a longer useful life and more energy can be extracted from the battery before it requires a recharge. This will allow the greenhouse to run on renewable energy even if there is no sun during the day.

Second, we recommend that the greenhouse have a backup connection to the grid. In case the solar system fails for some reason or if there is not enough solar production to power the greenhouse, the grid will kick in. In the beginning, there may be some kinks in the solar system, but regardless of this system and the weather, we still want to have a functioning greenhouse.

Technical Analysis Moving Forward

With the all the groundwork laid by our capstone and as well as the previous capstones, we believe that the project needs to focus on the specifics of construction. We have laid out the basic design elements that farmer Lisa desires as well as design tips we have come across in both research and in talking to professional farmers. We have also given a preliminary estimation of the feasibility of taking the greenhouse off the grid. Ideally, the next group would perform a detailed analysis of energy and heat transfer or a study of the electrical system. Given the resources that Lafayette has from the engineering department, it may be helpful to solicit the aid of engineering students and professors to analyze the fine technical details of the different systems. For example, electrical engineering students could tackle the automation of the greenhouses systems when the farmer is away from the farm. We also recommend that mechanical engineers do a heat transfer analysis on the hose-heating system so that specific calculations can provide more support for the feasibility of a solar system. This will not only engage these different communities but will make the greenhouse technically more successful. Hopefully, it can be a model for what small-scale agricultural college farms can have in terms of greenhouses.

In our next section, we go into our economic context.