This economic analysis details the potential costs of incorporating various artistic components as well as the fundamental construction costs needed to refurbish the existing bridge. This refurbish/artistic rendering stage only pertains to the scope of the physical bridge itself and the area of land within the dimensions of the bridge. Acknowledging that the entirety of the addition’s cost will need to be further elaborated in the future, this report will only discuss the known labor costs of refurbishing the bridge, the costs of materials for each potential conceptual design, and the cost of zoning and design inspection applications. Values of each task are either provided by CE473 – Senior Capstone Design II 2016 Report, the Department of Agriculture, or calculated based on the average unit costs of desired materials. Calculated values were made using the known linear dimensions of the bridge: 160 feet long by 12 feet; the linearity skews the actual area value because there is a slight curve in the bridge, but that is not included. Therefore, the bridge surface area value used in all calculations is 1,920 square feet. The analysis will also address the benefits and disbenefits of each design alternative in four unique bridge components: preconstruction (including debris removal and bridge reconstruction), flooring, railing, and roofing.

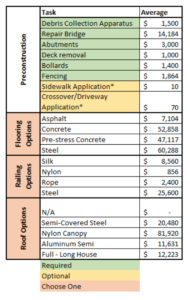

Figure 21: Pricing menu for possible construction components (Krackow, 2019)

Pre-construction, as detailed in Figure 21, is composed of various tasks and materials that are deemed critical for any advancement of the bridge that would allow for pedestrian access aside from implementing a sidewalk on the roadside and a crosswalk area. Those two tasks are optional and are at the discretion of the Karl Stirner Arts Trail Board. The values detailed below were provided by the technical report and are considered fixed in price or non-negotiable (Reeves et al., 2016). Within preconstruction, the tasks include basic tree removal and debris collection as well as refurbishing components of the existing bridge that are critical to have any additional weight built upon it. These technical values are validated by the structural analysis provided by the past Civil Engineering Capstone group. Additional costs for preconstruction that are acknowledged but not detailed in Figure 21 include renting and transporting trailers to the site for temporary construction offices, storage box rental, fencing, ribbons, grade stakes, and silt fences. Due to the lack of an established project schedule for the bridge addition, we are unable to make valid estimates for rental costs of these items. Based on the determined values, preconstruction will cost a minimum of roughly $23,000 with an additional $80 of applications and approvals.

Flooring

Keeping in mind the possibility of commissioning an artwork for the floor of the bridge, material options should be conducive as an artistic medium. Typically, a simple pedestrian bridge will have one of four materials as the main terrain of the bridge: asphalt, concrete, prestressed concrete, or steel. It is acknowledged that the refurbished wood decking could be a potential flooring option, however, it would not be the most viable medium for the anticipated mural design due to its short life span. The most cost effective material for the size of the bridge would be asphalt at roughly $4 per square foot (Forest Products, 2001). Asphalt would be a good material to use for paving the pathway because it can “be built more quickly and cost-effectively than other pavements” (“Benefits of Asphalt”, n.d.). It is also “the most recycled product in America” which makes it an environmentally friendly option (“Benefits of Asphalt”, n.d.). While there are some forms of asphalt that are not as environmentally conscious, as they release hydrocarbons that turn into pollution, warm asphalt mix would be a good choice for our project (Krow, n.d.). This type of mix should be considered in the future phases of our project as it does not need as many fossil fuels to make and emits less fumes (“Asphalt As A Paving Choice: The Pros And The Cons”, 2012). In general however, more maintenance needs to be done on asphalt compared to concrete since it requires resealing every few years to prevent cracking (Krow, n.d.). So, although the initial unit cost of asphalt is cheap, maintaining this material, or fixing it if it is not laid properly, could end up costing a lot of money and time.

Beyond asphalt, the values of other materials jump drastically with the second most cost effective option of prestressed concrete at roughly $25 per square foot (Forest Products, 2001). Prestressed concrete is concrete that is “compressed in areas that will be subjected to external loads or stresses” as to avoid using reinforced steel bars to provide that tensile strength (“Prestressed Concrete”, 2019). The main benefit of implementing prestressed concrete “is that it combines the high strength compressive properties of concrete with the high tensile strength of steel” and is more resistant to shocks and vibrations than normal” concrete (“Prestressed Concrete”, 2019). Using prestressed concrete to carry out the advancement of the bridge would also reduce further corrosion of the steel components that are part of the existing structure. However, “a high degree of workmanship and control” is necessary for using prestressed concrete and it is also expensive to prepare “the equipment required for producing” it (“Prestressed Concrete”, 2019). Following prestressed concrete, as a third alternative is standard concrete at about $28 per square foot (Forest Products, 2001). The main drawback from using standard concrete is its lack of tensile strength because it requires that reinforced steel bars be put in as well to provide that. However, some advantages of using concrete include high durability, negligible maintenance cost, its ability to withstand high temperatures and resist water and wind, and freedom from defects and flaws (“Advantages and Disadvantages of Concrete”, n.d.).

Lastly, the least cost effective option is steel at about $30 per square foot (Forest Products, 2001). It would be a great homage to the industrial history of the Lehigh Valley and the rusticated options locally make the chosen steel to be the cheapest of the steel derivatives. However, as stated in the technical report created by Professor McGuire, steel is prone to corrosion when outdoors. It is also a heavy material and can be hard to work with. But, steel is tough and strong (Snyder, 2013). Additionally, steel is an aesthetically pleasing material. “Architects praise the natural beauty of steel… and exposing it in the design of their structures to emphasize grace, slenderness, strength and transparency of frame” (“Advantages of Steel”, n.d.). In line with KSAT’s mission to keep sustainability as a priority, steel is “made of 88% recycled product, is fully recyclable in the future and can be reused without further processing” (“Advantages of Steel”, n.d.). Considering the variety of durability in these materials, flooring can cost between $7,000 and $61,000 excluding the commissioned timeline design.

Railings

Once the base is selected, the focus should shift to the safety railings that are currently nonexistent. Railing styles can range from intricate artistic sculptures rife with social motifs of the history of the Lehigh Valley industries to standard railings. Both will span the length of the bridge. The materials, however, are refined to four options based on those potential styles: silk, nylon, rope, and steel. These alternatives can be used cohesively or individually depending on the railing design selected. Silk, serving as a nod to the neighboring Silk Mill, runs rather costly due to its luxurious status at an average of $40 per yard or $13 per foot. Silk is a viable alternative for the exterior railings due to its heat resistant and drying properties (Industrial Catalogs, 2019). However, it is far too costly to use in this industrial setting. If the railing design preferred by the KSAT Board of Directors involves the silk elements, a more cost effective imitation is nylon. At roughly $8 per yard, nylon or rayon is the most cost effective of the four options (Industrial Catalogs, 2019). This artificial material has similar resilience to extreme weather, however, the tactile qualities are much harsher compared to silk, which would change the interactive experience of the materials tactility. A moderately cost efficient option is 3” manila rope at $15 per foot (Industrial Catalogs, 2019). This material is very frequently used for industrial architecture and has weather-proofing qualities, but it is far more rough in both touch and style compared to the other alternatives. Fraying is a definite concern if it will be frequently grabbed, implying a potential need to have more frequent maintenance and replacement. The last railing material option is 316-grade stainless steel at $80 per foot. This grade is ideal for exterior handrails due to its sleek shine and exceptional corrosion resistance promising a long life span with virtually no maintenance (Feeny, 2019). However, it can tarnish overtime and is incredibly expensive. Taking all styles and materials into account, railing costs can range from $850 to $26,000.

Roofing

Lastly, roof alternatives should be considered. Each style has a determined material associated with it, making the cost of each style fixed within the confines of this proposal. Potential roof options include a semi-enclosed steel barrier, a nylon canopy, aluminum awning, a full Lenni-Lenape inspired wooden longhouse, or no roof entirely. As logic would suggest, the least expensive option is to have no roof, but the lack of a defined, internal space eliminates a sense of monumentality within the structure and its possible functionality as an exhibition space for non weatherproofed works. Also, there is simply no protection for visitors in case of unfavorable weather or precipitation. The second most cost effective design is the aluminum awning, which evokes a rustic structure that is both purposeful and inviting. Only having the roof, creek viewing would not be inhibited while still providing protection from the sun and precipitation. With the average cost of aluminum running $4.50 per square foot, this design will cost roughly $11,600 to cover the expanse of the bridge. However, aluminum has a lighter density so more would need to be used to take on more stress (Snyder, 2013). The aluminum intended for this alternative will be of low grade and high malleability can be seen in Figure 22 and is similar to the flooring option.

Figure 22: Aluminum awning (Best of House, n.d.)

Used sparingly, this design could create a defined interior space, while also allowing a 360-degree viewing platform of the Bushkill Creek and surrounding landscape. It would cost roughly $20,500. Another semi-enclosed option is a nylon canopy that would offer more of a dynamic and airy space than the other options. Offering both protection and full viewing, this option provides a very artistic dimension to an otherwise traditional structure. However, it will be the most expensive due to the cost of nylon in mass quantities. This option would run about $82,000. The last option is a full longhouse to evoke the history of the tribe that once actively resided in the Bushkill watershed. In accordance with traditional building practices, the design will be composed of 2,640 feet of cedar wood creating a fully enclosed space along the KSAT costing roughly $12,300 (NYS, 2019). This design pays direct homage to the legacy of the Lenni-Lenape while promoting a sense of protection for both visitors and potential art installations on the bridge.

Exceeding the scope of this report, we also acknowledge post-construction costs that are included in the connection of the bridge addition to the existing trail. Post-construction values may include fence removal, debris collector removal, trailer removal, storage unit removal, and silt fence removal (Reeves et al., 2016). Unlike the aforementioned pre-construction cost, the action of these items is a one-time cost, however, we are unable to determine these values due to the unknown time and companies needed to acquire these rental items.

In summary, the total range of potential combinations of flooring, railing, and roof options ranges from $10,150 to $89,462, excluding labor costs. This figure may seem high, however, in total including labor costs, a simple pedestrian bridge will probably cost around $250,000 according to projected costs for the pedestrian bridge that crosses the Lehigh River in Bethlehem (Satullo, 2019).

Funding

Easton was recently awarded $1.3 million in federal grants for its Bushkill Corridor Safety Enhancements Project (Lehigh Valley, 2019). The project includes:

- “Developing alternative transportation links throughout the Bushkill Drive corridor.

- Constructing 610 feet of asphalt trail from the Karl Stirner Arts Trail north to Bushkill Drive.

- Rehabilitating a historic railroad trestle from Bushkill Drive to the arts trail, to be used as a pedestrian bridge.

- Adding 1,000 feet of 8-foot wide asphalt path.

- Adding 920 feet of concrete sidewalks and curbing.

- Repairing 300 feet of concrete sidewalk.

- Installing ADA ramps, streetlights, and landscaping.”

While the city was granted $1.3 million in federal grants, the total project cost is estimated to be around $1.57 million (Bresswein, 2019). The city is requesting waivers to lower this cost. Other ways in which this $270,000 gap can be closed is by raising donations or making a call to the community for capable volunteers, like they have done with other projects such as the musical playground. However, the article’s repetition of the rehabilitation of the historical railroad trestle leads us to believe that this is a condition, if not a priority, of the grant. Additionally, we acknowledge the required funding for the commissioned floor mural, but we do not know the exact cost because the value of the piece is indicated by the artist at the completion of the mural. Under these circumstances, funding will probably be acquired through KSAT’s channels of grants and private donors as a final economic installment prior to the integration of the bridge into the existing trail.

When it comes to the economic analysis of this project, many of the exact costs associated with the various components of our designs are unknown. Because this project is in its early stages and its focus is broader, our team has compiled ranges of costs for several features that we hope to see implemented if this project is well received by the Karl Stirner Arts Trail Board of Directors and Public Works.

To read the conclusive points of our project, click here.