The technical context that comes with mapping the life cycle of electronic waste is a grand portrait of the technologies we chose to analyze, bisected by the comparatively brief period of time during which the user interacts with the product. Though often absent from the mind of the consumer, what happens before and after the user’s time with the device is crucial to understanding a product’s life cycle.

For instance, Apple’s iPhone 6s is composed of much more than the handsome aluminum case and glass screen that users interact with. Within that aluminum casing lies the powerhouse of Apple’s smartphone, its lithium cobalt oxide battery which contains aluminum, cobalt, graphite, and lithium . Aluminum can also be found in elements of the smartphone’s screen. The micro-electrical connections within the phone utilize different elements for different applications. For instance, silver is used in areas of the device that require maximum conductivity, though gold connections are in place where longevity is of the highest priority, as gold never tarnishes. Copper and tungsten are utilized as well in electrical applications. Apple’s A9 processing chip is composed mainly of silicon, though it is treated with a variety of other elements to idealize its electrical properties (Desjardins, 2016).

Ethics are part of the conversation when it comes to the composition of micro-capacitors present in the iPhone 6s and various electronics across the market. Tantalum, the element used in manufacturing the micro-capacitors that control energy flow inside modern electronics is extracted from a dull ore called coltan. In 2013, 44% of the world’s tantalum came from coltan mined in the war-torn regions of the Democratic Republic of the Congo and Rwanda (Papp, 2015). The DRC is a perfect example of a country that has suffered from what is known as the resource curse. When a nation rich with resources begins profiting from those resources, those profits have a tendency to provoke and sustain internal conflicts as different groups fight over control of said resource (NGRI, 2015). A series of civil conflicts has made the DRC one of the most violent places in the world. More than five million have been killed in the DRC since 1998, and rape and slavery are far from uncommon (Browning, 2015).

Apple made a claim in 2014 that they had audited all smelters of tantalum in its supply chain, and that none of those smelters used tantalum mined from high-conflict areas of the Democratic Republic of the Congo (Browning, 2015). That being said, given the context in which coltan is mined in that area of the world, it is difficult for Apple or any electronics manufacturer to be sure that none of that material makes it into its products. Because tantalum ore is sold not through easily monitored commodities exchanges but through a network of undocumented dealers, regardless of the confidence with which Apple insists their tantalum is conflict free, it is impossible for them to say for sure.

Once consumers dispose of their electronics, we are faced as a society with a multitude of problems. There is far too much e-waste that is difficult to process, and e-waste presents enormous potential risks, though properly recycling e-waste presents enormous potential benefits when properly taken care of. Therefore, it is crucial that engineers and scientists find out how to treat these e-wastes wisely and efficiently. There are different approaches toward separating the valuable and potentially hazardous materials present in the electronic waste. For metals, methods are fusion, refinement, and electrolysis. For non-metals, methods are landfill, burning, and pneumatolysis.

E-waste is composed mainly of metals, ceramics, glass, resin fiber, plastics, rubber, semiconductors, and composites though the proportion of useful materials is higher than other forms of waste. (Kong, Liu, Zeng, 2012) Raising the percentage of e-waste that gets recycled would greatly reduce the amount of waste avoid additional environmental pollution. Some materials are harmful to the human body, some being extremely toxic. When the material is sent to a landfill or burned, the heavy metals therein penetrate into the soil, rivers, and groundwater, which will cause pollution to local soil and groundwater. Materials post-incineration release harmful gases such as highly toxic dioxins, furans, and polychlorinated biphenyls.

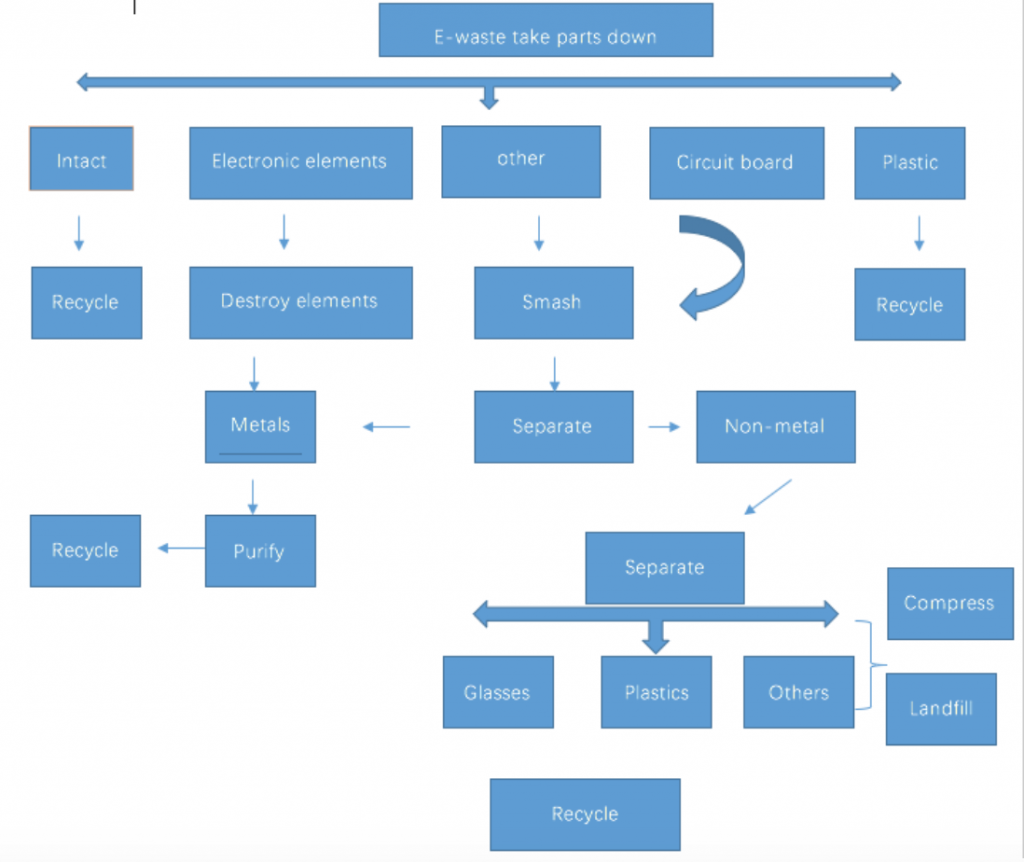

Below are charts showing the data relating to the E-waste recycle. Chart 1 shows the percentage of different components in several typical electronic devices. It provides a few examples from a computer to a dishwasher. The second chart shows the elemental breakdown of a wasted circuit board. The data reports the composition of a circuit board regarding different metals, oxides, and plastics. Chart 3 shows the process of the way in which society deals with electronic waste today. From the chart, we can see that we could be recycling the electronic elements, purified metals, plastics, and glasses. Following are the charts for the e-waste treatment-related information. The chart is cited from a Chinese version of paper by Chen and the following chart is a translated version) (Chen, 2013)

Chart 1: several typical electronic devices’ components (%) (Recycle model)

| type | Black metals | Non-ferrous metals | plastics | glass | circuit |

| computer | 32 | 3 | 22 | 15 | 23 |

| telephone | <1 | 4 | 69 | NA | 11 |

| tv | 10 | 4 | 10 | 41 | 7 |

| dishwasher | 51 | 4 | 15 | NA | <1 |

Chart 2: Wasted Circuit board’s typical component(%)

| component | % | component | % |

| Cn | 20 | Si | 15 |

| Zn | 1 | Al2O3 | 6 |

| Al | 2 | Alkane earth metal oxides | 6 |

| Pb | 2 | Other oxide total | 3 |

| Fe | 2 | Nitrogen containing polymers | 30 |

| Sn | 4 | C H O | 1 |

| Other | 1 | Halogen | 25 |

| Total | 40 | Plastic total | 30 |

Chart 3: Process

Even though there are sources of e-waste, there are commonalities in their materials. E-wastes are typically split into the printed circuit board, cable, wires, picture tubes, and other common components. How to recycle these materials has been a problem for a long time because if its complexity. During the 1970s, e-waste recycling was focused on the recovery of precious metals. But as the technology developed, we could also recover ferromagnetic material, non-ferrous metals, and organic substances. Many countries have performed research on the “disposal study” and developed ways to recover useful components, stabilize or remove harmful components, and reduce the impact on the environment. The current methods of disposal of electronic waste are chemical treatment methods, heat methods, mechanical treatment methods and electrochemical methods, or a combination of several methods.

Mechanical Treatment

Even though there are sources of e-waste, there are commonalities in their materials. E-wastes are typically split into the printed circuit board, cable, wires, picture tubes, and other common components. How to recycle these materials has been a problem for a long time because if its complexity. During the 1970s, e-waste recycling was focused on the recovery of precious metals. But as the technology developed, we could also recover ferromagnetic material, non-ferrous metals, and organic substances. Many countries have performed research on the “disposal study” and developed ways to recover useful components, stabilize or remove harmful components, and reduce the impact on the environment. The current methods of disposal of electronic waste are chemical treatment methods, heat methods, mechanical treatment methods and electrochemical methods, or a combination of several methods.

Disassembly of electronic waste is usually handled manually for recycling so useful electronic components can be collected. But due to a large number of components and the complexity of the devices hand-processing efficiency is very low. Japanese companies developed a set of automatic disassembly device that can separate these components. These devices mainly use infrared heating and in a two-stage (using vertical and horizontal impact force respectively), to perforate surface elements off. As a result, they will not cause any damage to the electronic elements. German companies use the automatic assembly of the circuit board which is the opposite principle of disassembly. They first put the wasted circuit board into the heated liquid and then melt it, then use a mechanical device to sort out available components based on their shape.

Breaking or crushing is a more efficient way to achieve the separation of electronic waste monomers. The key to making a device “Broken” is the choice of degree of fragmentation because it not only affects the energy consumption of crushing equipment but also affects the subsequent sorting efficiency. A device can be “Broken” through some methods, such as impact crushing, cutting, and crushing. Also, there is wet crushing and low-temperature crushing. The typical equipment involved in crushing includes hammers, choppers, rotary crushers, and many others. To improve e-waste crushing effects and reduce energy consumption for different materials we must choose the right way to crush, which depends on varying characteristics of materials.

The mechanical separation of electronic waste mainly draws on the physical differences between substances, such as density, electricity, magnetism, shape and surface characteristics, etc. Selecting the appropriate sorting method will greatly improve the efficiency of sorting, and reduce the difficulty of subsequent processing and improve recovery efficiency.

Mechanical treatment is currently the most widely used method of recovering precious metals from electronic waste. The snow treatment method is based on the physical characteristics of the material, such as density, conductivity, magnetism, and toughness. Mechanical treatment methods include manual or mechanical disassembly, crushing and sorting techniques.

E-waste can be rich in many types of precious metals. Among the existing methods for leaching metals such as gold, the cyanide leaching process is often applied. However, the toxicity of cyanide is extremely harmful to the environment and human health, greatly limiting the usage and net benefit of this method (Samantha Boh, 2016)

Thermo-metallurgy

By definition, “Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their intermetallic compounds, and their mixtures, which are called alloys.” Thus, thermo-metallurgy means using the heat and fire to study the chemical and physical properties of metals. The basic principle of pyrometallurgical metallurgy furnace is the use of high-temperature heat stripping of non-metallic materials, precious metals fused to other metal smelting materials or molten salt, and then be separated. Non-metallic substances are mainly organic materials on the printed circuit board, generally separated and removed from the scum, while precious metals and other metals were out of the state of gold, in the refining or electrolytic treatment. Metallurgical pyrometallurgical extraction of precious metals is simple, easy to operate and high recovery rate, but due to the presence of organic pollutants in the incineration process produces secondary pollution caused by harmful gases, a low recovery rate of other metals and processing equipment, and other shortcomings, the current method has been Gradually eliminated. (Thermal, Metallurgical and Mechanical Phenomena in the Heat Affected Zone)

Hydrometallurgy

The fundamental principle of hydrometallurgy technology is to utilize the chemical properties that allow precious metals to be dissolved in nitric acid or other reagents, separating precious metals from other substances and to recover them from the solution. The most commonly used in hydrometallurgy is nitric acid.

Hydrometallurgy takes place in three steps: pretreatment, leaching of the element, and precipitation. Select electronic waste containing precious metals is broken with a crusher to a certain particle size and then heated to 400 degrees Celsius to remove organic matter. The pretreated parts are immersed in a certain molar concentration of a nitric acid solution and heated. The precious metal, base metals, and metal oxides are dissolved in hot nitric acid and filtered to obtain a nitric acid solution containing the precious metal and other non-ferrous metals. Continue to soak plate with aqua regia, gold, palladium, and platinum dissolved in aqua regia solution, filtered, the filtrate after evaporation concentrated sodium sulfite or oxalic acid, formic acid, ferrous sulfate and other reducing agent precipitated gold in the filtrate, and then extract or ammonia precipitation Palladium and platinum in solution.

Compared with pyrometallurgical hydrometallurgy, hydrometallurgy has the advantages of less exhaust gas emission, easy extraction of precious metal residues, and significant economic benefits. The main disadvantage of hydrometallurgical technology is the expensive chemical reagents, complicated process and a large amount of waste water, which is hard to handle. At present, hydrometallurgy technology is still improving and developing. (Hydrometallurgy). The following equations show the chemical process of hydrometallurgy. (Progress of Electronic Waste Treatment) (Wu, Guo, 2006)

Hydrometallurgy Chemical Process

Ag+2HNO3= AgNO3+NO2↑+H2O

Au+4HCl+HNO3=HAuCl4+NO↑+2H2O

3Pt+18HCl+4HNO3=3HPtCl6+8H20+4NO↑

3Pd+18HCl+4HNO3=3HPtCl6+8H20+4NO↑

2HAuCl4+3Na2SO3+3H2O=2AU↓+3Na2SO4+2HCl

H2PtCl6+Na2SO3+H2O=H3PtCl4+Na2SO4+2HCl

Microorganisms

The use of microorganisms is a new technology. The use of microbial activity makes gold and other precious metal alloys and other non-precious metals oxidized into the solution and making metals to uncover themselves to collect easily. Biotechnology to extract gold has the advantages of simple process, low cost, and simple operation, however, the time for leaching is long. (NUS study)

Visuals

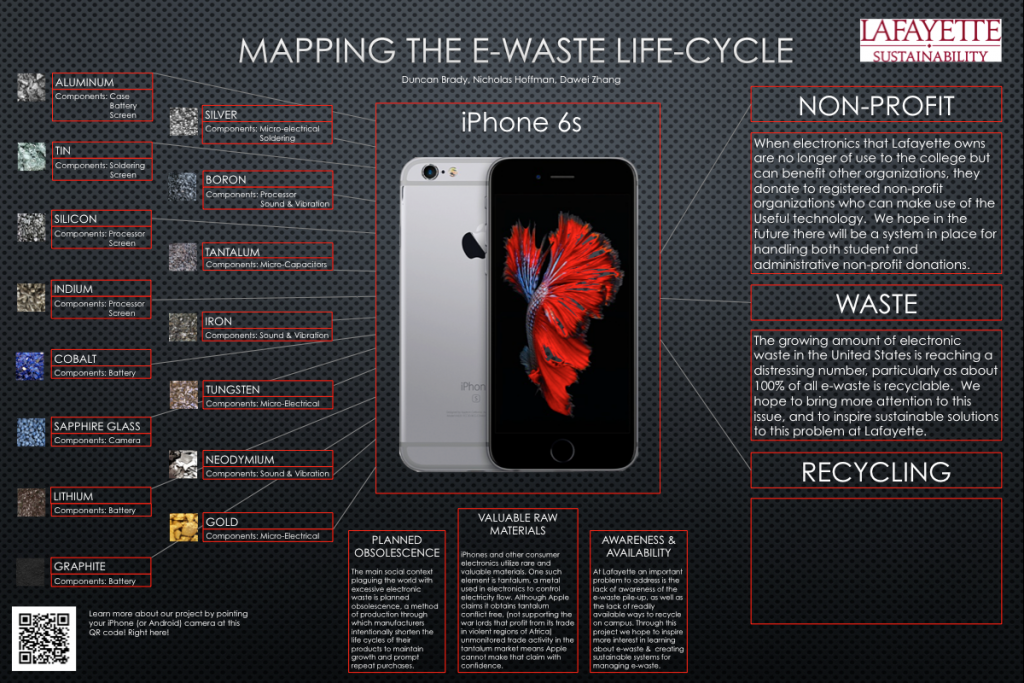

Our representation of the e-waste lifecycle at Lafayette will focus specifically on that of the iPhone 6s, released in September of 2015. Of students surveyed at Lafayette College, 85% owned a cell phone in Apple’s line of iPhones (Mapping the E-Waste Lifecycle, 2017). We feel that in order to have the most effective visual representation of the life cycle of electronic waste, it is necessary to focus in on a device that students are familiar with. Additionally, in researching the elemental breakdowns of smartphones, laptop computers, and high-definition televisions, we found that from an e-waste perspective these devices are largely the same. Therefore, an image of a 2015 model iPhone 6s will be the centerpiece of our diagram.

Information will be presented left-to-right, with the elemental breakdown of the phone on the left representing life before student ownership, and short paragraphs describing different potential paths for life after student ownership. We decided to present the information for before ownership based on the elements that make up components in the phone, rather than structuring based on the components themselves. Presenting the elements as the most important aspect of the pre-ownership life cycle emphasizes that these are the potentially valuable but also potentially harmful materials inside an iPhone that are so important to recycle or dispose of properly.

The structure of our design came from research regarding how members of the community respond to data being presented in different ways as well as how we anticipate students interacting with the design. Based on studies to examine how patients make decisions given health care information presented in different ways, people are more likely to make informed decisions when presented with visual cues rather than just a graphical data representation (Peters, 2007). Therefore, we added light gray lines connecting each element to the iPhone they would eventually amass and the same light gray lines connecting the iPhone to the different paths representing the end of its life cycle. This illustrates continuity across the figure, reminding the viewer that the elements on the left-hand side of the figure are the same materials being donated, recycled, or thrown away on the right-hand side. We also consciously avoided filling the poster with numbers and statistics, as information presented numerically can be less effective than information presented in prose. According to the National Adult Literacy Survey, almost 50% of American citizens lack the numerical literacy and mathematical skill necessary to process the numbers embedded in printed material (Kirsch, 2002). Although the level of numerical literacy is likely higher at a well regarded academic institution such as Lafayette, it is important that the visual representation of the life cycle be as accessible to the viewer as possible.

For those viewers who are interested in learning more about the details of our project, a QR code will be provided in the bottom left corner of the poster. Upon aiming the camera of an iPhone or similarly capable Android device, software within the device will extract a link from the QR code, prompting the user to visit the web page at that address. The code will link to the Electronic Lifecycle page at the Engineering Studies Fall 2017 Capstone website. There the reader will be presented with well-organized links to the different sections of our report, exploring the different contexts surrounding the issue. This resource will ensure that more information is available to those who seek it out, though it does not guarantee that the information will be current.

In order to maximize the longevity of our project, one section of our poster will remain blank by design. One of the three pathways we chose to highlight for post-ownership electronics is to recycle them as electronic waste. As we found that only 15% of students surveyed could confidently report that they knew how to recycle their e-waste, we thought it necessary to include a dynamic section of the poster to accurately report where students can recycle e-waste even as those locations change throughout the years (Mapping the E-Waste Lifecycle, 2017). The Office of Sustainability will be responsible for regularly updating the posters around campus to display up-to-date information on recycling locations.