With spring break right around the corner, we and our classmates will be boarding planes, crossing state lines, and traversing the globe in order to have the best #SB2K16 we so desperately need. Some of us will be traveling to other continents, going home or seeing friends abroad, while others will be traveling to a tropical place to catch some rays. What we all have in common though, is that we will all be kicking off our spring breaks by going through security, getting side-eyed by the TSA, boarding a plane and taking our seats (probably a middle seat lets be honest). Once we take off we’ll probably take out our phones and put some music on and try to go to sleep since our flight boarded so early. What we won’t think about though is how our plane is going to stay safe throughout our flight and allow us to breathe as we soar thousands of feet above land and sea.

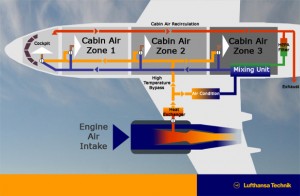

All planes are equipped with an environmental control system (ECS) that provides air supply, thermal control and cabin pressurization for the crew and passengers. The ECS is operated through a feedback system, therefore cabin pressurization and airflow is monitored and the air intake from the outside is adjusted accordingly. On aircrafts, air is supplied to the environmental control system by being “bled” from the compressor stage of a gas turbine engine. The temperature and pressure of the “bled” air varies depending on which stage of the compressor it is coming from, and the power setting that the engine is operating.  To control cabin pressure, air conditioned air from the ECS is pumped into the cabin of a plane to create a safe and comfortable environment for passengers and crew flying at high altitudes. The air supplied to the fuselage is cooled, humidified, and mixed with recirculated air before it is distributed to the cabin. Pressurization is necessary at altitudes above 12,500 to 14,000 feet above sea level to protect passengers and crew from health problems caused by the low outside air pressure above those altitudes but is a requirement for cruising altitudes above 8,000 feet.

To control cabin pressure, air conditioned air from the ECS is pumped into the cabin of a plane to create a safe and comfortable environment for passengers and crew flying at high altitudes. The air supplied to the fuselage is cooled, humidified, and mixed with recirculated air before it is distributed to the cabin. Pressurization is necessary at altitudes above 12,500 to 14,000 feet above sea level to protect passengers and crew from health problems caused by the low outside air pressure above those altitudes but is a requirement for cruising altitudes above 8,000 feet.

On the ground, the airplane is unpressurized and the outflow valve is wide open. During preflight, the pilot sets the cruise altitude on a cabin pressure controller. As soon as the weight is off the main wheels at takeoff, the outflow valve begins to close and the cabin starts to pressurize. The airplane may be climbing at thousands of feet per minute, but inside the cabin, the rate of “climb: is approximately what you might experience driving up a hill. It might take an average airliner about 20 minutes to reach a cruise altitude of approximately 35,000 feet, at which point the pressurization system maintains the cabin at the pressure you’d experience at 7,000 feet: about 11 pounds per square inch. Of course our ears may pop, however, the effect is mild because the rate of the climb is only about 350 feet per minute. When the airplane descends, the pilot sets the system controller to the altitude of the destination airport, and the process works in reverse.

The structural strength of the airplane determines how much differential pressure the cabin can tolerate—a typical figure is eight pounds per square inch—and the fuselages of new airplane designs are pressurized and depressurized many thousands of times during testing to ensure their integrity.  The higher the maximum differential pressure, the closer to sea level the system can maintain the cabin. Federal Aviation Regulations say that without pressurization, pilots begin to need oxygen when they fly above 12,500 feet for more than 30 minutes, and passengers have to use it continuously above 15,000.

The higher the maximum differential pressure, the closer to sea level the system can maintain the cabin. Federal Aviation Regulations say that without pressurization, pilots begin to need oxygen when they fly above 12,500 feet for more than 30 minutes, and passengers have to use it continuously above 15,000.

The structural strength of the airplane determines how much pressure the cabin can tolerate, a typical amount is about eight pounds per square inch, and the fuselages of new airplane designs are pressurized and depressurized many thousands of times during testing in order to ensure their integrity. Planes are designed so that occupants will not be exposed to altitudes over 25,000 feet for more than 2 minutes or at an altitude of 40,000 feet at any time. These regulations are in place in case of sudden decompression.

Pressurization is achieved by the design of an airtight fuselage engineered to be pressurized with a source of compressed air and controlled by an ecs. Air enters the system as bleed air which is extracted from the compressor stage of a gas turbine engine at a low stage and from an additional high stage. By the time the cold outside air has reached the bleed air valves, it is at a very high pressure and has been heated to about 200C. The control and selection of high or low bleed air sources is automatic and is governed by the requirements of various stages of flight. The part of the bleed air that is directed to the ecs is expanded and cooled to a suitable temperature by passing it though a heat exchanger and an air cycle machine called the packs system. At least 2 different engines provide the compressed bleed air for the plane’s ecs. Exhaust air is pumped into the atmosphere is an outflow valve, usually at the rear of the fuselage. This valve controls the cabin pressure and also acts as a safety relief valve. Is the automatic pressure controllers fail, the pilot can manually control the cabin pressure valve and the plane can still fly smoothly. The automatic controller normally maintains the proper cabin altitude by constantly adjusting the outflow valve position such that the cabin altitude pressure remains as low as possible without exceeding the limits of the fuselage.

Unplanned loss of cabin pressure at altitude is rare but has resulted in a number of fatal accidents. Failures range from sudden, catastrophic loss of airframe integrity, known as explosive decompression, to slow leaks or equipment malfunctions, that allow cabin pressure to drop undetected to levels that can lead to unconsciousness or severe performance degradation of the aircrew.

Any failure of cabin pressurization above 10,000 feet requires an emergency descent to approximately 8,000 feet or the closest to that while maintaining the Minimum Safe Altitude (MSA), and the deployment of an oxygen mask for each seat. The oxygen systems have sufficient oxygen for all on board and give the pilots adequate time to descend to below 8,000 ft. Without emergency oxygen, hypoxia may lead to loss of consciousness and a subsequent loss of control of the aircraft, since the time of useful consciousness varies according to altitude. As the pressure falls, the cabin air temperature may also plummet to the ambient outside temperature with a danger of hypothermia or frostbite. In jet fighter aircraft, the small size of the cockpit means that any decompression will be very rapid and would not allow the pilot time to put on an oxygen mask. Therefore, fighter jet pilots and aircrew are required to wear oxygen masks at all times.

So, the next time you’re on a flight and you’re thinking, “How the heck am I breathing right now?”, just refer to “The Mile High Club”, for everything you need to know about cabin pressure during air travel.  Once you read it you’ll start to realize that it’s a very complicated process you may never fully understand, nor do you really want to because who wants to be paranoid about cabin pressure for a whole flight? As long as your pilot shows up sober, you should be fine!

Once you read it you’ll start to realize that it’s a very complicated process you may never fully understand, nor do you really want to because who wants to be paranoid about cabin pressure for a whole flight? As long as your pilot shows up sober, you should be fine!