Do you often find yourself wondering just how much detergent you should put in that washing machine? And, with average hours of sleep dwindling and the working day increasing, sitting down and calculating just the right amount of detergent to use is implausible, or in the words of the Internet Sensation “Sweet Brown” Wilkins, “Ain’t nobody got time fo’ that”. And, sometimes, the result is ugly. I’d have a pair of shoes washed with the washing machine filled with bubbles. Hmmm… However, now we have the new option of using an automatic washing machine which not only does that calculation for us, but also determines the optimal mode itself so that water, detergent and electricity are saved. The way an automatic washing machine does it? Fuzzy control! And we are all about that fuzz here.

Conventionally, our manipulated variables, such as washing time, quantity of detergent, water level, washing temperature, and spinning speed have been determined by people through trial-and-error. It had been difficult to develop automatic washing machines, as the relationships between inputs to the controller, such as volume of clothing, quality of fabric, quantity of dirt, and type of dirt, and outputs from the controller, which are our manipulated variables, are not clear. However, Lofti Zadeh, a mathematician and computer scientist developed the concept of fuzzy logic, as he realized that while a lot of decisions have to be made based on imprecise or non-numerical information, our computers are digital devices that operate in the two states of zero and one, or in other words, operate on “hard logic”. Using a fuzzy controller, automatic washing machine can make sound decisions even when a precise input-output model is not available.

To explain how fuzzy controller works in an automatic washing machine, we use a simplified model where only quantity of dirt and type of dirt are considered as inputs to the controller. An optical sensor is used to measure the transparency of the water, by which the quantity of dirt is then determined. The type of dirt is determined by the different saturation points, as some dirt, such as grease, is less soluble in water and therefore takes longer time to saturate water (water is saturated when the water transparency is almost zero). Each of these two inputs “quantity_of_dirt” and “type_of_dirt” are presented on a scale from 0% to 100%. The decision which the fuzzy controller makes is derived from the rules which are stored in the database as if-then statements as follow:

- If quantity_of_dirt is Large and type_of_dirt is Greasy then wash_time is VeryLong;

- If quantity_of_dirt is Medium and type_of_dirt is Greasy then wash_time is Long;

- If quantity_of_dirt is Small and type_of_dirt is Greasy then wash_time is Long;

- If quantity_of_dirt is Large and type_of_dirt is Medium then wash_time is Long;

- If quantity_of_dirt is Medium and type_of_dirt is Medium then wash_time is Medium;

- If quantity_of_dirt is Small and type_of_dirt is Medium then wash_time is Medium;

- If quantity_of_dirt is Large and type_of_dirt is NotGreasy then wash_time is Medium;

- If quantity_of_dirt is Medium and type_of_dirt is NotGreasy then wash_time is Short;

- If quantity_of_dirt is Small and type_of_dirt is NotGreasy then wash_time is VeryShort

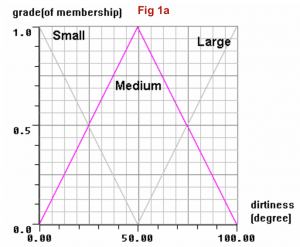

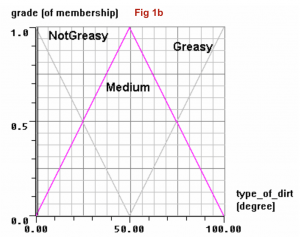

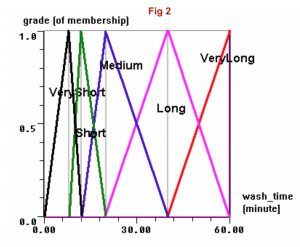

These rules can be shown as Gaussian membership functions with inputs shown in Fig. 1a and 1b and outputs shown in Fig 2:

Degrees of membership (DOM) are calculated for each inputs. The sum of Output Component (which equals “Input DOM x Output Set Value” for each component ) is the value for our Crisp Output “wash_time”. A signal is then sent so that the correct washing time will be implemented.

The process for an automatic washing machine is a batch process. A feedback control strategy is used, as the controller takes into consideration the degree of cleanliness (our controlled variable) that we desire in order to make the decision and take action on the manipulated variables. Even though a simple model is used in our case to demonstrate the determination of washing time, we know that this model could be expanded to other manipulated variables such as quantity of detergent, water level, washing temperature, and spinning speed by adding other sensors. For example, by using neuro fuzzy control, fabric type of clothing can be detected by the sensor and the correct spinning speed can be determined to avoid extra creasing of the clothing. The fuzzy controller has also been introduced to the drier to avoid overheating of the clothing by inadvertent human error.

In future, a reiterated process may be used to improve the performance of fuzzy control. The optical sensor could be used to measure the cleanliness of the clothing after the first wash. In this way, should disturbances such as too little detergent added occur and the washing result be less than satisfactory, another wash with corrected action would be implemented using the same process.

Bibliography

Agarwal, M. (n.d.). Retrieved from Tripod: http://softcomputing.tripod.com/sample_termpaper.pdf

Cole, G. (1995, 12 1). Fuzzy Logic, Fabulous Performance. Accountancy.

Fuzzy Control of Washing Machines. (n.d.). Retrieved April 1, 2016, from Concernergy: http://www.concernergy.com/index.php/residential_appliances_fuzzy-control-of-washing-machines_197#more

Fuzzy Logic. (n.d.). Retrieved April 1, 2016, from http://mathematica.ludibunda.ch/fuzzy-logic6.html

Neha Virkhare, R. J. (2014, 1). Neuro-Fuzzy Controller Based Washing Machine. International Journal of Engineering Science Invention, 48-51.

The idea of a washing machine that can optimize the amount of water and detergent needed to wash a particular load is a great idea that I could see myself and the majority of the population using. Even though washing machines have become more efficient over the last few years with respect to their water and electricity usage, they still have plenty of room for improvement. One of the biggest problems with washing machines is that the cheaper models have very limited settings which do not cover all the various types of loads being washed and that the more expensive models have too many settings which causes the average user to become confused with the correct settings to use. The fuzzy controller can fix all these issues by calculating the optimal conditions automatically.

The controlled variable for this process is the cleanliness of the clothes after they are washed. I agree with many of the suggested manipulated variables that the article suggests such as the amount of detergent used, the amount of water in the machine at one time, the water temperature, the washing time, the and spin speed. Since some newer washing machines have “spherical” drums that allow for more directions of rotation, spin direction could also be considered as a manipulated variable. Other possible manipulated variables are the rate of draining of the dirty water and the rate of refilling of the clean water. All of these variables can be manipulated rather easily since they only require the washer to make a few valve adjustments. Some of the disturbance variable for the process are related the properties and the quantity of the dirt on the clothing. The controller will have to continuously correct for the dirt being removed from the clothes and added to the water. The article suggests that an optical sensor should be used to determine the amount of dirt currently in the water. However, this may not be an effective method since different types of dirt absorb light in different ways. For example, a small amount of black dye will have a huge effect on the water transparency while dirt such as gasoline or clean motor oil will have little impact on the transparency of the water. Including a concentration sensor along with the optical sensor may be a good way to overcome this challenge.

This process would be most benefited by a feedback control scheme. This is because it is relatively easy to determine the current conditions in the washer and react to them by adjusting the manipulated variables. A P controller or a PI controller should be used to control the process. Derivative action is unnecessary since a quick response is not needed and since there will be a large amount of random noise do to imperfect mixing leading to concentration gradients in the water. It would probably be best to tune the controller via an open loop method since it will be difficult to determine the ultimate gain and ultimate period for the closed loop method.

This application is quite clever. I definitely envision the process of combining fuzzy logic with washing machines being implemented in both personal and commercial settings. Specifically, in commercial settings, a completely automated washing system could allow businesses to open up that wash your laundry for you. Imagine a place you could go where you just put your clothes in and the rest is taken care of. I also imagine this being used in athletic settings. Imagine how efficiently athletic uniforms for professional and varsity teams could be washed if you combine fuzzy logic with washing machines. Lastly, I can envision this being further developed where the system could automatically shift the clothes into a dryer, which would automatically dry them (without having to remember to switch the clothes over yourself).

It definitely makes sense to control the cleanliness of the clothes. More specifically, we want to control the amount of dirt/grease/grime that is extracted from the clothes. This requires the manipulations of water level, detergent amount, and cycle time (both wash and spin cycles). I think it is easiest to manipulate detergent and water amounts. However, cycle time could be adjusted instantaneously as the cycle proceeds, in response to when the clothes are deemed “clean enough.” Potential disturbances seem to be volume of clothing, fabric quality of clothing, type of dirt/grease/grime, and amount of dirt/grease/grime. The controlled, manipulated and disturbance variables you chose are absolutely appropriate for the purposes of this class. I am just so excited about the incredible complexity this system could handle when designed by a team of professional process engineers.

It seems this process will be noisy in terms of both mechanical functions and disturbance variables. The dirt/filth/grime in the system, will change as the cycle proceeds. In addition, no two cycles will contain the exact same amounts or types of dirt/filth/grime. In addition to your fuzzy logic controller, I think a simple PI controller would work best in order to have the system respond during the cycle.

All in all, this sounds like an awesome process and I hope to see it developed further!

I think the idea of having a fuzzy control is a rather novel one with a myriad of possible applications. The concept of digital which bolsters many of our modern signal controlled systems is robust but behind the time. Fuzzy control’s ability to provide greater control discretion to a user is significant and therefore could lead to improvements in various existing systems.

The system chosen for this project – Washing Machine – is a crucial one. The biggest setback seen in washing machines is the excessive time taken to go through a cycle, which is often a deterrent to time strapped young individuals (students and professionals). Lack of responses to load size, and levels of dirt often lead to thee excessive time taken for the system. Utilizing a process control would be innovative by lowering the time taken for a cycle, which would be extremely beneficial.

The variables used, seem about alright. I was curious if you could have a minimum time period for clothes which aren’t visibly dirty as is often the case. Most people don’t wait for their clothes to get rather dirty to wash them. The sensors used appear efficient enough in doing the job. My only concern here would be the way clothes are tumbled and put in a washing machine, how would that hinder the efficacy of a sensor if say the stains were hidden the pile of fabric.

The simulink idea put in is novel, and unlike ones seen in class. It’s interesting to look at the various functions of Simulink, which can be utilized to solve complex problems such as the ones seen here. I would recommend using a PI controller due to the two variables being considered here. Further, an offshot seen in a PID controller could have a detrimental effect on the fabric of the clothing. Great job guys!