Do you often find yourself wondering just how much detergent you should put in that washing machine? And, with average hours of sleep dwindling and the working day increasing, sitting down and calculating just the right amount of detergent to use is implausible, or in the words of the Internet Sensation “Sweet Brown” Wilkins, “Ain’t nobody got time fo’ that”. And, sometimes, the result is ugly. I’d have a pair of shoes washed with the washing machine filled with bubbles. Hmmm… However, now we have the new option of using an automatic washing machine which not only does that calculation for us, but also determines the optimal mode itself so that water, detergent and electricity are saved. The way an automatic washing machine does it? Fuzzy control! And we are all about that fuzz here.

Conventionally, our manipulated variables, such as washing time, quantity of detergent, water level, washing temperature, and spinning speed have been determined by people through trial-and-error. It had been difficult to develop automatic washing machines, as the relationships between inputs to the controller, such as volume of clothing, quality of fabric, quantity of dirt, and type of dirt, and outputs from the controller, which are our manipulated variables, are not clear. However, Lofti Zadeh, a mathematician and computer scientist developed the concept of fuzzy logic, as he realized that while a lot of decisions have to be made based on imprecise or non-numerical information, our computers are digital devices that operate in the two states of zero and one, or in other words, operate on “hard logic”. Using a fuzzy controller, automatic washing machine can make sound decisions even when a precise input-output model is not available.

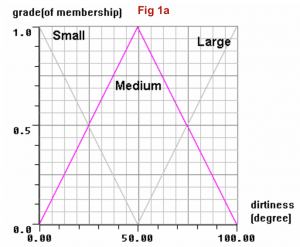

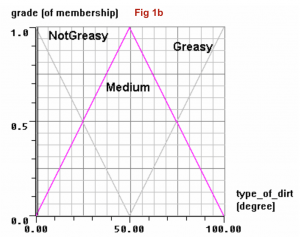

To explain how fuzzy controller works in an automatic washing machine, we use a simplified model where only quantity of dirt and type of dirt are considered as inputs to the controller. An optical sensor is used to measure the transparency of the water, by which the quantity of dirt is then determined. The type of dirt is determined by the different saturation points, as some dirt, such as grease, is less soluble in water and therefore takes longer time to saturate water (water is saturated when the water transparency is almost zero). Each of these two inputs “quantity_of_dirt” and “type_of_dirt” are presented on a scale from 0% to 100%. The decision which the fuzzy controller makes is derived from the rules which are stored in the database as if-then statements as follow:

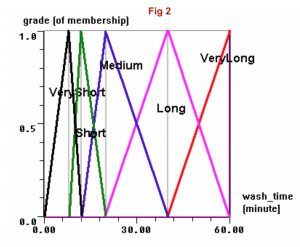

- If quantity_of_dirt is Large and type_of_dirt is Greasy then wash_time is VeryLong;

- If quantity_of_dirt is Medium and type_of_dirt is Greasy then wash_time is Long;

- If quantity_of_dirt is Small and type_of_dirt is Greasy then wash_time is Long;

- If quantity_of_dirt is Large and type_of_dirt is Medium then wash_time is Long;

- If quantity_of_dirt is Medium and type_of_dirt is Medium then wash_time is Medium;

- If quantity_of_dirt is Small and type_of_dirt is Medium then wash_time is Medium;

- If quantity_of_dirt is Large and type_of_dirt is NotGreasy then wash_time is Medium;

- If quantity_of_dirt is Medium and type_of_dirt is NotGreasy then wash_time is Short;

- If quantity_of_dirt is Small and type_of_dirt is NotGreasy then wash_time is VeryShort

These rules can be shown as Gaussian membership functions with inputs shown in Fig. 1a and 1b and outputs shown in Fig 2:

Degrees of membership (DOM) are calculated for each inputs. The sum of Output Component (which equals “Input DOM x Output Set Value” for each component ) is the value for our Crisp Output “wash_time”. A signal is then sent so that the correct washing time will be implemented.

The process for an automatic washing machine is a batch process. A feedback control strategy is used, as the controller takes into consideration the degree of cleanliness (our controlled variable) that we desire in order to make the decision and take action on the manipulated variables. Even though a simple model is used in our case to demonstrate the determination of washing time, we know that this model could be expanded to other manipulated variables such as quantity of detergent, water level, washing temperature, and spinning speed by adding other sensors. For example, by using neuro fuzzy control, fabric type of clothing can be detected by the sensor and the correct spinning speed can be determined to avoid extra creasing of the clothing. The fuzzy controller has also been introduced to the drier to avoid overheating of the clothing by inadvertent human error.

In future, a reiterated process may be used to improve the performance of fuzzy control. The optical sensor could be used to measure the cleanliness of the clothing after the first wash. In this way, should disturbances such as too little detergent added occur and the washing result be less than satisfactory, another wash with corrected action would be implemented using the same process.

Bibliography

Agarwal, M. (n.d.). Retrieved from Tripod: http://softcomputing.tripod.com/sample_termpaper.pdf

Cole, G. (1995, 12 1). Fuzzy Logic, Fabulous Performance. Accountancy.

Fuzzy Control of Washing Machines. (n.d.). Retrieved April 1, 2016, from Concernergy: http://www.concernergy.com/index.php/residential_appliances_fuzzy-control-of-washing-machines_197#more

Fuzzy Logic. (n.d.). Retrieved April 1, 2016, from http://mathematica.ludibunda.ch/fuzzy-logic6.html

Neha Virkhare, R. J. (2014, 1). Neuro-Fuzzy Controller Based Washing Machine. International Journal of Engineering Science Invention, 48-51.