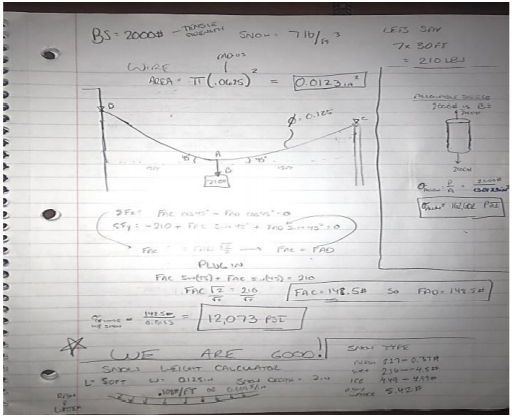

Calculations for Wires

Jordan provided basic calculations. To further analyze professional structural information of the product refer to US cargo control.

Calculations have been provided to further the analysis of the wire

NOTICE: Calculation is an unrealistic representation of project design. Calculations are done this way just to provide evidence of sound structure requirements.

Assumptions:

210 lbs weight directly in the middle of the structured wire.

Assumed 45-degree angle exit point for wires

Knowns:

Area of wire= 0.0123sqin

Break Strength (BS)= 2000 lbs

Normal allowable stress:

Normal allowable stress= BS/A= 2000 lbs/0.0123sqin

Normal allowable stress= 162,602 PSI

Wire on each side of 210 lbs weight holds 148.5 lbs

Normal Stress on Wire= 148.5 lbs/0.0123sqin

Normal Stress on Wire= 12,073PSI

12,073 PSI < 162,602 PSI So wire is safe and will not break

Snow weight calculator- Done to provide realistic evidence on our wire

Wire width= 0.125in

Snow depth= 2 in

L= 50 ft max length of wire distance

Weights below are calculated based on

Fresh snow 0.27-0.37 lbs

Wet snow 2.16-4.5 lbs

Ice 4.49-4.99 lbs

rain/water 5.42 lbs

* No rain, snow, or water will be able to sit on ⅛ in diameter wire at 2 in

Taking the max weight of 5.42 lbs calculate the max load upon the wire as a whole for 50ft

Load=5.42 lbs/50ft

Load=.108 lbs/ft or .0009 lbs/in

Loads must be extremely heavy in one given point to cause failure of break strength. Due to the design of the project, the wire will not encounter any super heavy loads. Realistically the only loads it may experience are snow, rain, or a small animal, which will not provide enough stress to cause failure to wire rope.

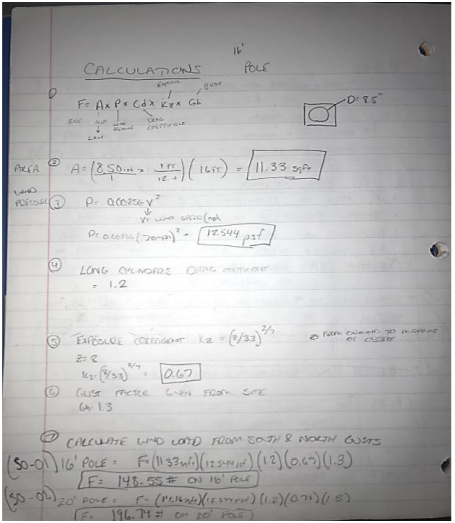

Calculations for Spires

Jordan provided basic calculations. To further analyze professional structural information of the product refer to Valmont Structures.

Calculations provided further the evidence for this spire being the top choice. The calculations were completed using the estimated projected area calculations along with simple shear stress calculations. Based upon the equation engineers use to understand force from wind and the stress it places on the spire, the spire shows no results of failure.

Equation

F=A x P x Cd x Kz x Gh

A= area wind hits (Varied upon height of spire)

P=Wind pressure

Cd= Drag Coefficient

Kz= Exposure

Gh= gust factor

Wind pressure equation

P=0.00256(V)^2 where V is wind speed

V=70 mph based on American Association of State Highway and Transportation Officials

Cd Long cylinders standard coefficient

Cd=1.2

Kz equation

Kz=(z/33)^(2/7)

z= from ground to midpoint of structure

Gust factor

Gh=1.3 given from Valmont Structure website (load and dimensional data)

Wind Gusts from North and South will provide force

S0-01 16’ spire= 148.55 lbs

S0-02 20’ spire= 196.74 lbs

S0-03 25’6” spire= 268.6 lbs

S0-04 28’6” spire= 312.12 lbs

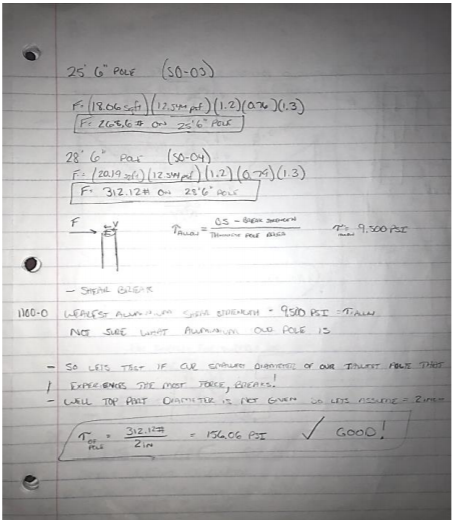

Shear strength

1100-0 is the weakest aluminum metal

Known shear strength (T) = 9,500psi

Test our structures greatest force applied to it to see if it fails

T= F/A

A= is smallest diameter of spire, most likely near top of spire

T=312.12 lbs/2in

T=156.06 PSI

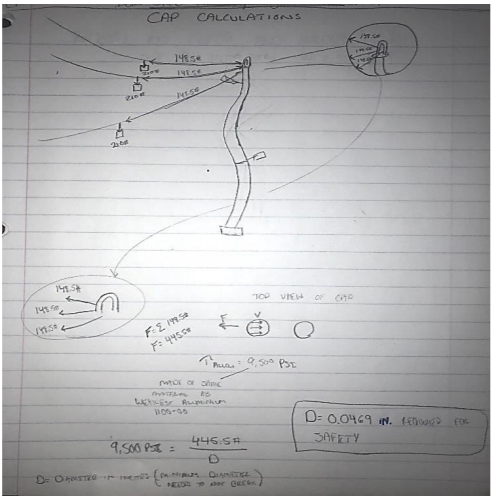

Calculations for Cap of Spire with 3 wires

Jordan provided basic calculations. To further analyze professional structural information of the product refer to Valmont Structures and US Cargo Control.

Note* Structural integrity will most likely be determined by the furnishing of spire caps.

For the spires with three wires connecting to it, they will have the highest load and force applied to the spire cap. The calculations below determine the minimum diameter of the cap connector to ensure the wires do not cause failure to the connector.

1 Wire = 148.5 lbs refer to Calculation for Wire for more information.

Cap with 3 wires

F=445.5 lbs

Shear stress allowed (T)= 9,500psi from 1100-0 Weakest Aluminum Metal

Stress Equation

9,500psi= 445.5 lbs/D

D= minimum diameter needed for safe structure

D=0.0469 inches

Structure will be structurally safe as long as cap is furnished with aluminum and has a diameter equal to or greater than 0.0469 in.

All structures should be feasible for use.