What are the Major Advantages and Disadvantages associated with Hybrid Electric Vehicles?

Switching to a HEV can provide the consumer with a multitude of benefits and advantages. The most useful benefit, however, is simple: hybrids are more economical. This is true for a number of reasons. HEVs achieve better fuel economy and have lower fuel costs than similar conventional vehicles. For example, the 2012 Honda Civic Hybrid has an EPA combined city-and-highway fuel economy estimate of 44 miles per gallon, while the estimate for the conventional 2012 Civic (four cylinder, automatic) is 32 miles per gallon. Want to check if a specific hybrid can save you money? Click here and allow the U.S. Department of Energy to tell you themselves. For a side by side comparison of different hybrids, click here.

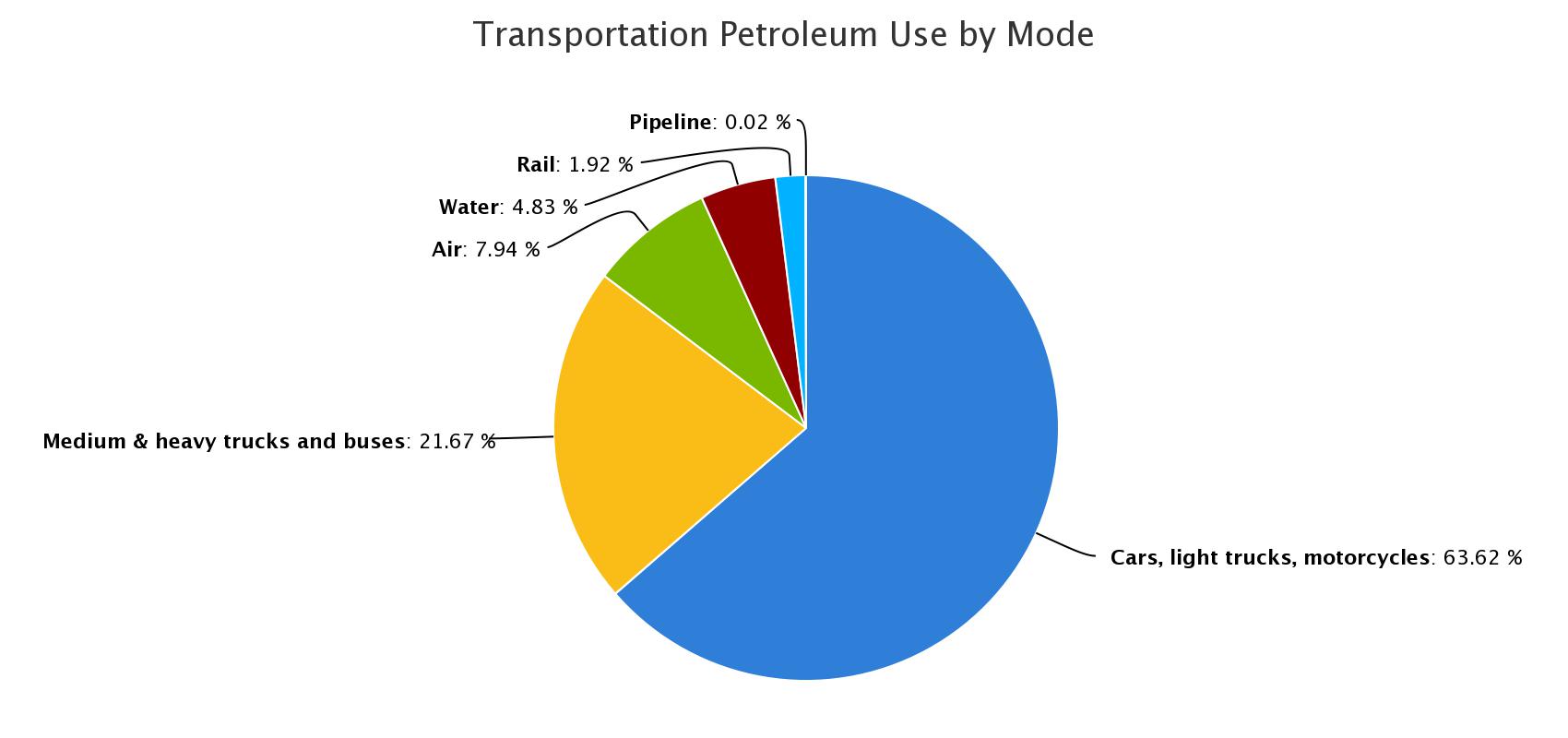

As mentioned on the Alternative fuel vehicles page, transportation accounts for 28% of total U.S. energy consumption. Shown below is a chart showing the breakdown of this consumption, within the transportation industry (alternative fuels data center).

Additionally, in 2013, the United States imported about 33% of the petroleum it consumed, a dependence that cost the U.S. economy $200 billion that year. Based on these numbers transportation was responsible for nearly three-quarters of total U.S. petroleum consumption. With much of the world’s petroleum reserves located in politically volatile countries, the United States is vulnerable to price spikes and supply disruptions.Using hybrid electric vehicles instead of conventional vehicles can help reduce U.S. reliance on imported petroleum and increase energy security. Hybrid electric vehicles (HEVs) use less fuel than similar conventional vehicles, because they employ electric-drive technologies to boost efficiency. Plug-in hybrid electric vehicles (PHEVs) and all-electric vehicles (EVs) are both capable of using off-board sources of electricity, and almost all U.S. electricity is produced from domestic coal, nuclear energy, natural gas, and renewable resources.

Although fuel costs for HEVs will be lower than for similar conventional vehicles, purchase prices can be significantly higher. However, higher capital costs are most likely to be offset by significantly lower operating costs over time. Prices are also likely to decrease as production volume increases. The initial costs can also be offset by federal tax credit and state incentives. To check on state laws and incentives for each state, click here. For federal tax credits per manufacturer and make, click here. Better yet, for a comprehensive calculation on vehicle cost, based on make & model, daily driving distances, and percentage driven on highways, click here.

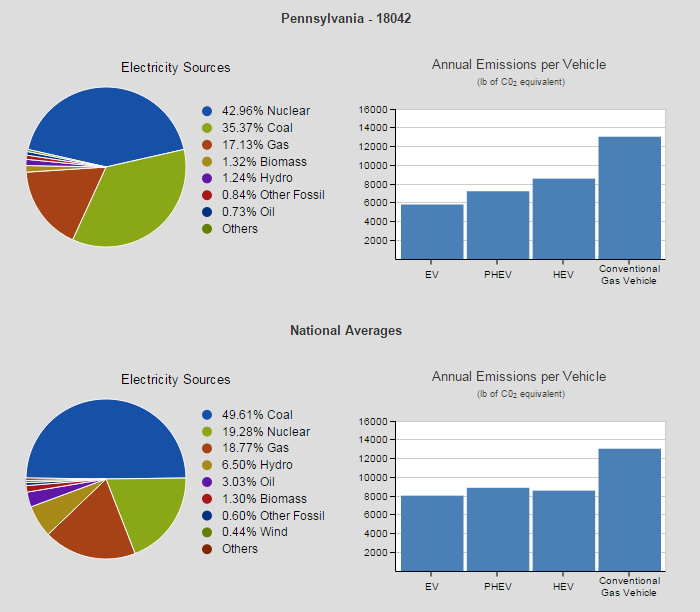

Hybrid electric vehicles also have significant emissions benefits over conventional vehicles. Even though HEV emissions benefits vary by vehicle model and type of hybrid power system, HEVs almost always have lower greenhouse gas emissions compared to their conventional counterparts. If the HEV is running purely on electricity (at low speeds), this could even result in zero tailpipe emissions temporarily. Shown below are two graphs showing life cycle GHGs of HEVs relative to both conventional vehicles, and PHEVs.

Additionally, shown below is a comparison of annual vehicle emissions and electricity sources between Easton, PA and U.S. averages.

Other advantages associated with HEVs can sometimes even include higher resale value. With HEVs becoming increasingly popular, and due to its advantageous technology, HEVs can often have higher resale value. Hybrid vehicles are also built using lighter materials. This results in the vehicle requiring less energy to run. The engine is also smaller (due to electric battery) and lighter, which also saves energy.

As for other challenges, few disadvantages have been found/reported with HEVs. However, among those found and reported, an important challenge is reduced power, thereby making it more suited for city driving. On some occasions HEVs can also be heavier than their conventional counterparts, due to lighter gasoline powered engine, electric engine and batteries, outweighing the conventional car’s gasoline engine. This results in manufacturers taking up seat space and sometimes less support in the suspension and body, which also results in poor handling. Last but not least, more car batteries need to be produced, creating a larger problem for their disposal. This could be a serious environmental challenge in the future, given the rapid increase in hybrid vehicles on U.S. roads.

Additional Information

Availability

Dozens of light-duty HEV models are available from major auto manufacturers. Shown below is a graph showing AFV and HEV model offerings, by manufacturer.

Additionally, shown below is a graph showing U.S. HEV sales by model, from 2000 – 2013.

A variety of medium and heavy-duty options are also available. For further information regarding alternative fuel and advanced medium & heavy – duty vehicles, click here.

Conversions

A conventional vehicle can also be converted to a hybrid electric vehicle. And an HEV can be converted to a PHEV or an EV. Such conversions provide options beyond what is available from original equipment manufacturers (OEMs). Certified installers can economically and reliably convert many light duty and heavy duty vehicles to operate on electricity to potentially improve the efficiency of conventional vehicle designs. To learn more about vehicle conversions, click here.

Batteries

Energy storage systems, usually batteries, are essential for electric drive vehicles, such as hybrid electric vehicles. The following energy storage systems are used in hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and all-electric vehicles (EVs).

- Lithium-Ion Batteries

Lithium-ion batteries are currently used in most portable consumer electronics such as cell phones and laptops because of their high energy per unit mass relative to other electrical energy storage systems. They also have a high power-to-weight ratio, high energy efficiency, good high-temperature performance, and low self-discharge. Most components of lithium-ion batteries can be recycled. - Nickel-Metal Hydride batteries

Nickel-metal hydride batteries, used routinely in computer and medical equipment, offer reasonable specific energy and specific power capabilities. Nickel-metal hydride batteries have a much longer life cycle than lead-acid batteries and are safe and abuse tolerant. These batteries have been used successfully in all-electric vehicles and are widely used in hybrid electric vehicles. The main challenges with nickel-metal hydride batteries are their high cost, high self-discharge and heat generation at high temperatures, and the need to control hydrogen loss. - Lead-Acid Batteries

Lead-acid batteries can be designed to be high power and are inexpensive, safe, and reliable. However, low specific energy, poor cold-temperature performance, and short calendar and cycle life impede their use. Advanced high-power lead-acid batteries are being developed, but these batteries are only used in commercially-available electric drive vehicles for ancillary loads. - Ultracapacitors

Ultracapacitors store energy in a polarized liquid between an electrode and an electrolyte. Energy storage capacity increases as the liquid’s surface area increases. Ultracapacitors can provide vehicles additional power during acceleration and hill climbing and help recover braking energy. They may also be useful as secondary energy-storage devices in electric drive vehicles because they help electrochemical batteries level load power.

Safety

Commercially available HEVs must meet the Federal Motor Vehicle Safety Standards and undergo the same rigorous safety testing as conventional vehicles sold in the United States. HEVs have high-voltage electrical systems that range from 100 to 600 volts. Their battery packs are encased in sealed shells and meet testing standards that subject batteries to conditions such as overcharge, vibration, extreme temperatures, short circuit, humidity, fire, collision, and water immersion. Manufacturers design these vehicles with insulated high-voltage lines and safety features that deactivate the electrical system when they detect a collision or short circuit.

Maintenance

Because HEVs have internal combustion engines (ICEs), their maintenance requirements are similar to those of conventional vehicles. The electrical system (battery, motor, and associated electronics) requires minimal scheduled maintenance. Break systems on HEVs typically last longer than those on conventional vehicles, because regenerative braking reduces wear.

Author: Raji Gunasekera

Editor: Justin Pie

References

http://www.fueleconomy.gov/feg/hybridtech.shtml

http://cta.ornl.gov/vtmarketreport/pdf/2014_vtmarketreport_full_doc.pdf

http://www.afdc.energy.gov/fuels/electricity.html

http://www.rmi.org/Content/Files/Technical%20and%20feasible.pdf

Samaras, C., & Meisterling, K. (2008). Life cycle assessment of greenhouse gas emissions from plug-in hybrid vehicles: Implications for policy. Environment Science Technology