Are you sick and tired of watered down iced-coffee? Do you wish that your iced coffee didn’t become diluted over time? What we propose is both a solution to this problem as well as a novel use of common appliances. Even if you don’t

drink iced coffee, our design concept can shift your view of processes that you may take for granted. While this system can operate at both personal and industrial scales, we envision this system as being most economically relevant on an industrial scale. With the commercialization of coffee ice cubes, private coffee shops and commercial coffeehouse chains will be able to provide their customers with higher quality iced coffee. Our system revolves around the design and control of a process that will brew, store, and freeze coffee. The end result will be frozen coffee that can be dispensed like standard ice cubes.

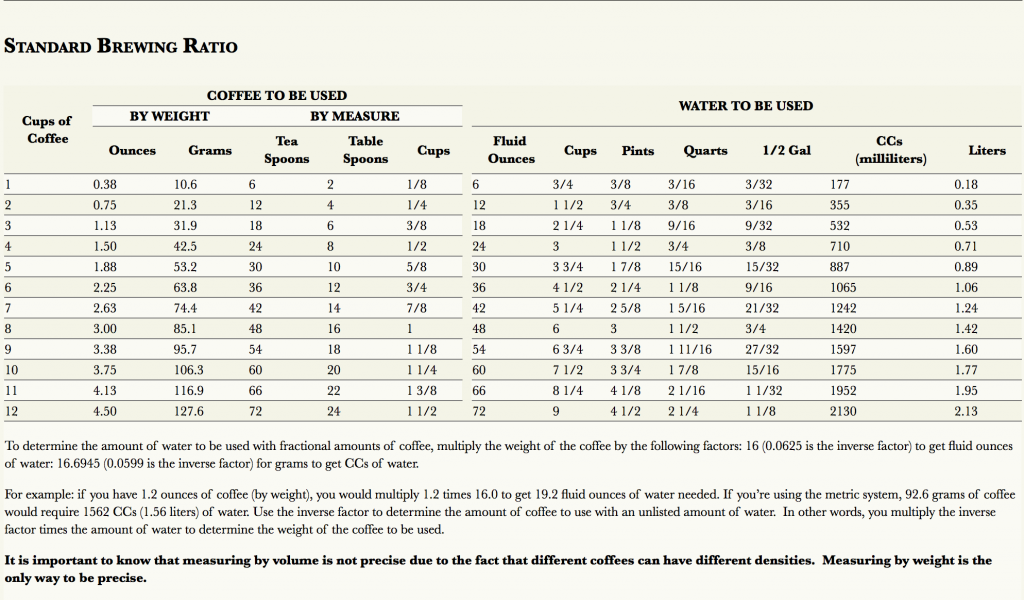

The process begins with the brewing of coffee. More specifically, we will be using a french press system. First, 12.78L of tap or distilled water will be added to the 20L brew vessel. The vessel will then heat the water to 96℃ (with an allowable deviation of -5°C) (1). After this temperature is reached, 0.7656 kg of medium ground coffee beans will be added to the tank. The tank will be stirred vigorously for 10 seconds, then brewed for 4 minutes. After 4 minutes, a european style plunger will gently push the grounds to the bottom of the tank.

The coffee will drain into an air pot style reservoir, then the bottom of the tank will open and dump the used grounds. This brewing process will repeat once the used grounds are dumped and the bottom of the tank is resealed (2). The air pot reservoir will be held at a temperature around 4℃. As fresh, hot coffee is added to the reservoir, the refrigeration will intensify to bring the contents to an equilibrium temperature of 4℃.

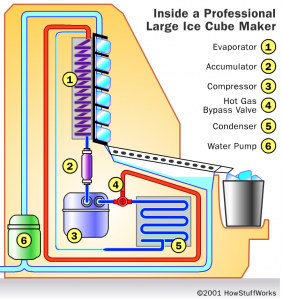

The next part of the system will be modeled after an automatic commercial ice cube machine. The coffee from the reservoir will be pumped out and allowed to flow continuously over an ice tray that is cooled via heat-exchanging pipes. These pipes cool the tray by allowing a compressor to cycle refrigerant fluid

through a condenser, then an evaporator. The constant condensation and expansion of the refrigerant draw heat away from the tray, allowing it to freeze the coffee (3). Once the cubes are formed, which takes approximately 15-40 minutes, a hot gas valve will open and cause the refrigerant to bypass the condensing stage. This results in an increase in temperature of the heat-exchanging pipes, subsequently causing the cubes to melt slightly and release from the tray (4).

The cubes will fall into the storage bin, which will be maintained at a temperature below -25℃, which is the eutectic temperature of brewed coffee (5). As the bin fills up, the ice will come into contact with a “thermostatic bin control thermal well” which will open and signal the ice machine to shut down until the bin needs to be replenished (6).

To begin organizing the overall process, we have determined which variables need to be controlled within the system:

- the temperature at which the coffee brews;

- the concentration of brewed coffee;

- the temperature at which the coffee is stored;

- the temperature at which the coffee is frozen;

- the temperature at which the coffee cubes are stored.

In this system, temperature is critical to the production, storage and freezing of the coffee. Consequently, there should be a relatively narrow effective temperature range for each step in the process. While heating the water which will be used to brew the coffee, it is important to ensure that the water reaches its minimum brewing temperature, 91℃, but does not exceed its ideal brewing temperature, 96℃. Exceeding this temperature, especially if the water were to reach its boiling point, 100℃, will burn the coffee, ruining the batch.

When it comes to storage, the air pot style reservoir will need to account for increases in temperature that occur due to the addition of freshly brewed coffee as it equilibrates to 4℃, an acceptable storage and preservation temperature. The temperature at which the coffee is frozen and the cubes are stored must be controlled at a set point below -25℃, the freezing point of brewed coffee. Rising above the freezing point will be incredibly detrimental to this process because it will prevent the formation of product — coffee ice cubes.

In order to control the aforementioned variables, an additional set of variables must be manipulated. The temperature at which the coffee brews will be controlled by a heating apparatus surrounding the brewing vessel. This is done to ensure an even distribution of heat. There will be a sensor within the tank to determine when its overall temperature is within the acceptable range.

The temperature of the systems that require cooling will also be monitored by an internal sensor. A continual disturbance within the system is the addition of fresh, hot coffee being added to the refrigerated reservoir. As the temperature increases, the sensor within the cooling reservoir will send a feedback signal to a fail-close valve that will increase the flow of refrigerant to the heat-exchanging pipes. If the aforementioned disturbance is not accounted for quickly enough, there will be a fail-open valve that prevents the coffee from leaving the storage reservoir until the contents reach the 4℃ set point. Similarly, as operators retrieve coffee ice cubes from the storage unit, the temperature of the unit will increase. This periodic temperature change will be regulated in a similar fashion to the air pot style reservoir.

To maximize consumer satisfaction, the concentration of the coffee will also be controlled. In order to control the concentration, a sensor will be located within the air pot style storage reservoir, which will be continuously stirred to maintain an even concentration. This sensor will be connected to the water pipe that feeds into the brew tank. The signal from the sensor will regulate the amount of time that the valve is open in order to adjust the amount of water entering the brew vessel. The ability to manipulate the flow of water allows operators to set their desired strength of coffee while also ensuring the the quality of each ice cube is nearly identical.

While one could control the amount of ground coffee beans entering the system, it is less practical than manipulating the flow of water. The addition of water has a direct effect on the overall volume of the tank. However, the addition of coffee beans has an indirect effect on volume since it is directly dependent on the mass of the bean. Manipulation of flow rate of water ensures that the tank will not overflow, which is highly important on an industrial scale. Lastly, the length of time that the coffee brews in the vessel will be manually set by operators depending on their preferences.

No system is perfect, so we must account for and correct errors that will arise throughout the process. In addition to the disturbances discussed above, another potential perturbation can arise during the brewing stage of this process. Although our system will automatically release coffee grounds each time the brew vessel finishes draining, there is a possibility that solid residue will build up in the bottom and on the sides of the brew vessel. To account for this buildup, there will be a sensor that monitors the volume inside the tank. If the volume starts to increase above the set value of 17L, it will notify the system to shut down, and indicate to the operator that the brew vessel must be cleaned.

The commercialization of coffee ice cubes is an innovation that will revolutionize the coffee consumption industry. Through the combination and modification of commercial scale coffee production and commercial scale ice cube production processes, coffee — a precious life-sustaining elixir — can now be consumed in both liquid and solid states.

~ Sara Mikovic, Owen Robinette, Rachel Tritt

Sources

- The Black Bear Micro Roastery. How to Brew “the Perfect Cup” of Coffee. https://blackbearcoffee.com/resources/87 (accessed Mar 30, 2016).

- The Black Bear Micro Roastery. Common Methods of Brewing Coffee. https://blackbearcoffee.com/resources/88?destination=resources (accessed Mar 30, 2016).

- How Stuff Works. Home and Garden: How Icemakers Work. http://home.howstuffworks.com/icemaker2.htm (accessed Mar 30, 2016).

- The Legacy Companies. Automatic Commercial Ice Cube Maker: User’s Manual. p14. http://www.maxximumfoodservice.com/pages/en/Manuals/MIM250-user-manual.pdf (accessed Mar 30, 2016).

- ed. Clarke, R. J. and Macrae, R. Coffee, Vol. 1: Chemistry. Elsevier Science Publishers Ltd, 1989. Scribd. https://www.scribd.com/doc/298880795/19/Freezing-Point-Depression (accessed Mar 30, 2016).

- Ice-O-Matic. Installation, Start-Up and Maintenance Manual. http://www.iceomatic.com/uploadedFiles/Shared_Content/Product_Content/Downloads/Owner,_Instruction_Manuals/FlakerInstall1008.pdf (accessed Mar 30, 2016).

- Liliana Fuchs. Iced Coffee. Flickr. (accessed Apr 01, 2016). license: https://creativecommons.org/licenses/by/2.0/legalcode

- LaVange, Don. I like Coffee in the Mornings. Flickr. (accessed Mar 30, 2016). license: https://creativecommons.org/licenses/by-sa/2.0/legalcode

One of the more modern iced coffee drinks is to pour milk over coffee iced cubes and then wait for them to melt. The machine described by Owen, Sara, and Rachel would effectively and efficiently commercialize this drink for large scale operations using existing technology. Because this application utilizes a machine already in production without major modifications it should fall within a reasonable cost analysis for implementation and could go to market quickly. The real challenge would be increasing the size of tank where the coffee is brewing to achieve maximum profit per use. It would also be interesting to investigate the application for central manufacturing and national or regional distribution. The need for specific temperature would expand as you incorporated semi-trucks and additional handling.

The controls for this process are heavily temperature based and all do require strict control with little to no room for overshoot error. I propose that with the little room for overshoot the accuracy of the temperature monitors will need to measure to multiple decimal places to for the sake of accuracy. The heat input manipulations will require PID controls. The integral control will help to modulate the regular disturbance of the addition of coffee to the air tank. While the derivative control will maintain the strict nature of the control variables, by responding quickly. This system and has strict no overshoot needs so regulation should be concerned about derivative controller kicks, however the speed at which it responds to disturbances is also important for the maximum efficiency of this machine. This system will require different control setting for the concentration of the coffee but will require the same time of controller because both the speed of response and understanding of past patterns of change will be important for quality control. It might also be reasonable to manipulate the time of brewing to control the overall coffee concentration in the storage tank as necessary to maintain quality of product. To that end, I would suggest adding some kind of human tasting control to the storage tank because no computer will be able to better determine taste then the human brain. The described fail-open and fail-closed valves are well placed and will definitely help maintain the strict temperature guidelines. The monitor for cleaning the brewing tank also accounts for another disturbance variable which would clearly effect the uniformity of product.

I think this application makes sense. At first glance, I thought maybe it would be easier just to use more concentrated coffee poured over ice so that the melting ice cubes would dilute the beverage to the proper coffee concentration. The problem with this is that the concentration would not stay constant over time, and the coffee would be too concentrated until the ice completely melted, at which point the temperature would no longer be regulated by the melting ice. Making coffee ice cubes is a good solution to this problem because it keeps the concentration constant during the entire coffee drinking experience. As far as adopting the process goes, I think it is possible that coffee shops would consider purchasing the coffee ice maker. These shops sell hundreds of cups of iced coffee every day, so the investment, probably at least around five thousand dollars for an industrial unit, may be worthwhile to attract additional customers. I would not expect home coffee ice makers to be successful because of the cost. A personal unit would probably cost on the order of five hundred dollars, which would be too expensive for the typical consumer who could just put coffee in an ice cube tray in their existing freezer. It is possible that a home unit could be produced in smaller quantities and marketed as a luxury good, since many people do spend thousands of dollars on espresso machines.

As an addition, it might be a good idea to add a heat exchanger to the system. A heater is being used to increase the water temperature for brewing the coffee and then a refrigeration unit is being used to cool the coffee down and freeze it. By running the brewed coffee and feed water counter-currently, heating and cooling energy costs would be greatly reduced. The feed water would not need to be heated as much, and the brewed coffee would be pre-cooled before being frozen.

As for the control portion of the coffee-cube maker, I think all of the selected controlled variables (temperature and concentration of the coffee throughout the process) make sense. Temperature and concentration are the two factors that would most effect the quality of the coffee. I also think the manipulated variables described made sense. I think the disturbance variables where temperature in unexpectedly affected, like someone opening the door to remove ice cubes, make sense. I do not think the addition of fresh hot coffee being added to the refrigerator reservoir is a disturbance, since it is part of the process that it is also being controlled. It will impact the transfer functions, but not as a disturbance.

I think that PI controllers should be used to control brewing temperature, coffee concentration, and storage temperature. I think a PID should be used to control the temperature at which coffee cubes are stored. This is because opening the door could quickly make a drastic change in the storage area temperature, so a PID would be able to respond more quickly to the heat loss.

I think this application makes a lot of practical sense. This new product idea, which is a compilation of various smaller processes that exist already, adds a unique twist to traditional iced coffee making. As an iced coffee drinker, and not a hot coffee drinker (at last not very often), I could definitely see myself using this product. This seems very useful for both a coffee addict’s home (who drinks a lot of iced coffee), as well as larger commercial use in restaurants or coffee shops. I think having the ability to customize the strength of your coffee ice cubes may be unnecessary. It may be best to just make them all of an average or even strong concentrated coffee. This won’t water down your coffee too much, and a slightly stronger concentration will not hurt it either especially with the assumingly large volume difference between the liquid coffee and the solid coffee.

I think the controlled variables you mentioned are important variables to control. In terms of disturbance variables, I don’t think the fail-open and fail-close valves are needed in order to keep the stored coffee at 4 degrees Celsius. If the coffee is going to take a approximately the same time to brew each time, and if the coffee will take around the same time to freeze into cubes each time, it may not be necessary to add those valves. You can just increase the flow rate of the refrigerant if the coffee needs to be cooled faster, and then not begin brewing another pot until the stored coffee is cold enough. Another disturbance variable could be a power surge or outage which could cause a malfunction in some of the electrical parts. I think a manipulated variable that was not mentioned in the article is the flow rate of the refrigerant which would have a direct effect on the temperature and effectiveness of the cooling apparatus.

A feedback loop is the best application for this process as it would be hard to measure all of your disturbance variables to implement feedforward control. I also believe that for your system, a PID controller would work best. The integral controller will account for sustained error which may be very helpful for your process where disturbances such as the user opening up the container to remove ice cubes may last a while. Also, with limited noise, having derivative control will not be a problem. You would also want a responsive process in order to have minimal overshoot because with the critical upper and lower limit for your temperature set points, you will find it important to not have an overshoot. Internal Model Control would also work well because it will allow for any disturbances that may arise. I think this sounds like a very fun idea, and I wish you the best in your next steps on this project.

I think that the coffee cube maker is a great idea. I only like iced coffee and I have struggled with this problem a lot. I always drink my iced coffee too quickly because I don’t want the ice cubes to melt (which isn’t good because it makes my stomach hurt). The coffee cube maker adds a cool and unique twist on the traditional coffee maker. I agree that it would a great product for the coffee industry. You could sell it to large coffee companies (i.e. Starbucks and Dunkin Donuts). It would also be great to have in homes.

I think that your controlled variables are stop on. The temperature at which the coffee brews, the concentration of brewed coffee, the temperature at which the coffee is stored the temperature at which the coffee is frozen, and the temperature at which the coffee cubes are stored all make sense for your product. For the disturbance variables, I’m not sure that the addition of fresh, hot coffee being added to the refrigerated reservoir is a disturbance variable. I think that would be considered part of the process itself. I thought that your manipulated variable was also very accurate. The temperature at which the coffee brews will be controlled by a heating apparatus surrounding the brewing vessel would be a potential manipulated variable.

For your block diagram, a feedback loop would be the most appropriate. It would be difficult to implement a feedforward loop into your diagram. I also think that for your system, a PID controller would work best. There wouldn’t be a lot of noise in your process so the derivative aspect of the controller will work well with your product. The integral aspect will account for sustained error which would be very useful for your process. There will be overshoot, but it will be minimum. For your system, it’s not a huge deal if there’s an overshoot (for our product, the self-regulating treadmill, overshoot would cause a lot of issues).

I thought that the diagrams, pictures, and videos that were used in the blog were very helpful in my understanding of the product and all the details about it. I thought it was very well explained as well. I think this is a great product and I hope to see it in use one day. I know I would definitely use it.

This product makes a great deal of sense from a practical viewpoint. Replacing traditional ice coffees, this would add further convenience to the lives of ice coffee drinkers and would be a prime sell for coffee companies. The aspect of the proposed process I really appreciate is how it seeks to bring together existing processes and methodologies for a uniquely new, cumulative one.

There are several control variables defined for the process: the brewed coffee’s concentration, its brewing, storage and freezing temperature. All of these make sense for the purpose of having a consistent quality of final products. The manipulated variable made sense. The disturbance variable choice doesn’t necessarily convince me, as addition of hot coffee could be viewed as a change in set point rather than a disturbance per se. Disturbance variables to be considered would be ambience temperature changes that could potentially affect the internal temperature of the machine in case certain parts are uninsulated.

A feed forward/ feedback system would be ideal but extremely difficult to implement as this would involve putting in sensors to detect a variety of disturbance variables, which could be costly. A simple feedback system would therefore seem more practical and more cost effective.

A PI controller or a PID controller, depending on individual costs would both be appropriate for most of the processes. However, a PID controller would still be optimal in the coffee brewing and freezing processes as sudden changes in ambient temperature could upset the process and result in a lower quality product, so a derivative control that would take that change into account would be ideal to maintain a stable temperature for the respective processes.