Are you sick and tired of watered down iced-coffee? Do you wish that your iced coffee didn’t become diluted over time? What we propose is both a solution to this problem as well as a novel use of common appliances. Even if you don’t

drink iced coffee, our design concept can shift your view of processes that you may take for granted. While this system can operate at both personal and industrial scales, we envision this system as being most economically relevant on an industrial scale. With the commercialization of coffee ice cubes, private coffee shops and commercial coffeehouse chains will be able to provide their customers with higher quality iced coffee. Our system revolves around the design and control of a process that will brew, store, and freeze coffee. The end result will be frozen coffee that can be dispensed like standard ice cubes.

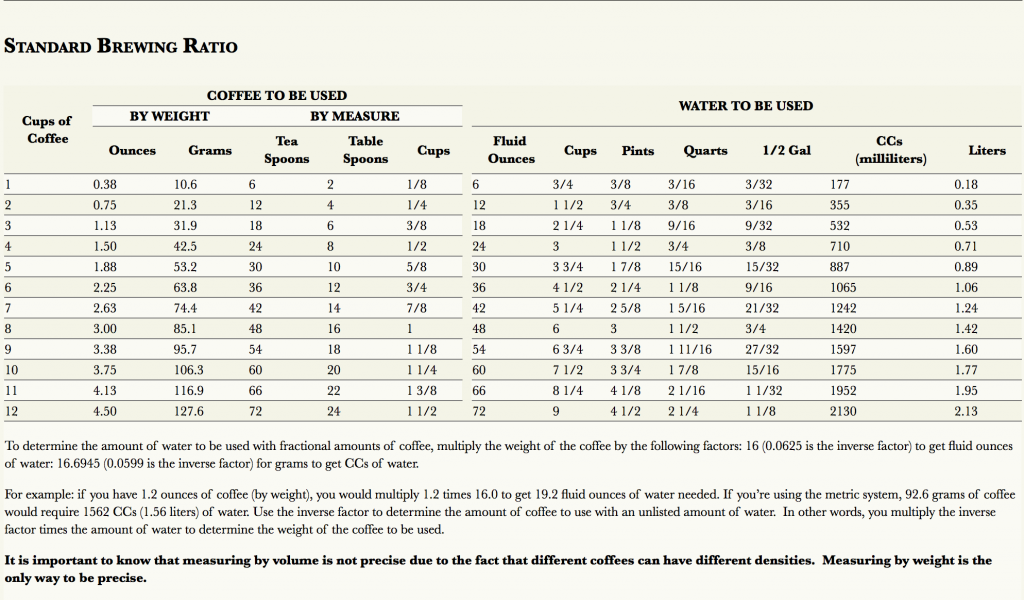

The process begins with the brewing of coffee. More specifically, we will be using a french press system. First, 12.78L of tap or distilled water will be added to the 20L brew vessel. The vessel will then heat the water to 96℃ (with an allowable deviation of -5°C) (1). After this temperature is reached, 0.7656 kg of medium ground coffee beans will be added to the tank. The tank will be stirred vigorously for 10 seconds, then brewed for 4 minutes. After 4 minutes, a european style plunger will gently push the grounds to the bottom of the tank.

The coffee will drain into an air pot style reservoir, then the bottom of the tank will open and dump the used grounds. This brewing process will repeat once the used grounds are dumped and the bottom of the tank is resealed (2). The air pot reservoir will be held at a temperature around 4℃. As fresh, hot coffee is added to the reservoir, the refrigeration will intensify to bring the contents to an equilibrium temperature of 4℃.

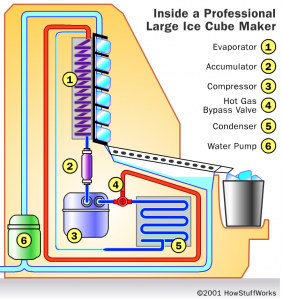

The next part of the system will be modeled after an automatic commercial ice cube machine. The coffee from the reservoir will be pumped out and allowed to flow continuously over an ice tray that is cooled via heat-exchanging pipes. These pipes cool the tray by allowing a compressor to cycle refrigerant fluid

through a condenser, then an evaporator. The constant condensation and expansion of the refrigerant draw heat away from the tray, allowing it to freeze the coffee (3). Once the cubes are formed, which takes approximately 15-40 minutes, a hot gas valve will open and cause the refrigerant to bypass the condensing stage. This results in an increase in temperature of the heat-exchanging pipes, subsequently causing the cubes to melt slightly and release from the tray (4).

The cubes will fall into the storage bin, which will be maintained at a temperature below -25℃, which is the eutectic temperature of brewed coffee (5). As the bin fills up, the ice will come into contact with a “thermostatic bin control thermal well” which will open and signal the ice machine to shut down until the bin needs to be replenished (6).

To begin organizing the overall process, we have determined which variables need to be controlled within the system:

- the temperature at which the coffee brews;

- the concentration of brewed coffee;

- the temperature at which the coffee is stored;

- the temperature at which the coffee is frozen;

- the temperature at which the coffee cubes are stored.

In this system, temperature is critical to the production, storage and freezing of the coffee. Consequently, there should be a relatively narrow effective temperature range for each step in the process. While heating the water which will be used to brew the coffee, it is important to ensure that the water reaches its minimum brewing temperature, 91℃, but does not exceed its ideal brewing temperature, 96℃. Exceeding this temperature, especially if the water were to reach its boiling point, 100℃, will burn the coffee, ruining the batch.

When it comes to storage, the air pot style reservoir will need to account for increases in temperature that occur due to the addition of freshly brewed coffee as it equilibrates to 4℃, an acceptable storage and preservation temperature. The temperature at which the coffee is frozen and the cubes are stored must be controlled at a set point below -25℃, the freezing point of brewed coffee. Rising above the freezing point will be incredibly detrimental to this process because it will prevent the formation of product — coffee ice cubes.

In order to control the aforementioned variables, an additional set of variables must be manipulated. The temperature at which the coffee brews will be controlled by a heating apparatus surrounding the brewing vessel. This is done to ensure an even distribution of heat. There will be a sensor within the tank to determine when its overall temperature is within the acceptable range.

The temperature of the systems that require cooling will also be monitored by an internal sensor. A continual disturbance within the system is the addition of fresh, hot coffee being added to the refrigerated reservoir. As the temperature increases, the sensor within the cooling reservoir will send a feedback signal to a fail-close valve that will increase the flow of refrigerant to the heat-exchanging pipes. If the aforementioned disturbance is not accounted for quickly enough, there will be a fail-open valve that prevents the coffee from leaving the storage reservoir until the contents reach the 4℃ set point. Similarly, as operators retrieve coffee ice cubes from the storage unit, the temperature of the unit will increase. This periodic temperature change will be regulated in a similar fashion to the air pot style reservoir.

To maximize consumer satisfaction, the concentration of the coffee will also be controlled. In order to control the concentration, a sensor will be located within the air pot style storage reservoir, which will be continuously stirred to maintain an even concentration. This sensor will be connected to the water pipe that feeds into the brew tank. The signal from the sensor will regulate the amount of time that the valve is open in order to adjust the amount of water entering the brew vessel. The ability to manipulate the flow of water allows operators to set their desired strength of coffee while also ensuring the the quality of each ice cube is nearly identical.

While one could control the amount of ground coffee beans entering the system, it is less practical than manipulating the flow of water. The addition of water has a direct effect on the overall volume of the tank. However, the addition of coffee beans has an indirect effect on volume since it is directly dependent on the mass of the bean. Manipulation of flow rate of water ensures that the tank will not overflow, which is highly important on an industrial scale. Lastly, the length of time that the coffee brews in the vessel will be manually set by operators depending on their preferences.

No system is perfect, so we must account for and correct errors that will arise throughout the process. In addition to the disturbances discussed above, another potential perturbation can arise during the brewing stage of this process. Although our system will automatically release coffee grounds each time the brew vessel finishes draining, there is a possibility that solid residue will build up in the bottom and on the sides of the brew vessel. To account for this buildup, there will be a sensor that monitors the volume inside the tank. If the volume starts to increase above the set value of 17L, it will notify the system to shut down, and indicate to the operator that the brew vessel must be cleaned.

The commercialization of coffee ice cubes is an innovation that will revolutionize the coffee consumption industry. Through the combination and modification of commercial scale coffee production and commercial scale ice cube production processes, coffee — a precious life-sustaining elixir — can now be consumed in both liquid and solid states.

~ Sara Mikovic, Owen Robinette, Rachel Tritt

Sources

- The Black Bear Micro Roastery. How to Brew “the Perfect Cup” of Coffee. https://blackbearcoffee.com/resources/87 (accessed Mar 30, 2016).

- The Black Bear Micro Roastery. Common Methods of Brewing Coffee. https://blackbearcoffee.com/resources/88?destination=resources (accessed Mar 30, 2016).

- How Stuff Works. Home and Garden: How Icemakers Work. http://home.howstuffworks.com/icemaker2.htm (accessed Mar 30, 2016).

- The Legacy Companies. Automatic Commercial Ice Cube Maker: User’s Manual. p14. http://www.maxximumfoodservice.com/pages/en/Manuals/MIM250-user-manual.pdf (accessed Mar 30, 2016).

- ed. Clarke, R. J. and Macrae, R. Coffee, Vol. 1: Chemistry. Elsevier Science Publishers Ltd, 1989. Scribd. https://www.scribd.com/doc/298880795/19/Freezing-Point-Depression (accessed Mar 30, 2016).

- Ice-O-Matic. Installation, Start-Up and Maintenance Manual. http://www.iceomatic.com/uploadedFiles/Shared_Content/Product_Content/Downloads/Owner,_Instruction_Manuals/FlakerInstall1008.pdf (accessed Mar 30, 2016).

- Liliana Fuchs. Iced Coffee. Flickr. (accessed Apr 01, 2016). license: https://creativecommons.org/licenses/by/2.0/legalcode

- LaVange, Don. I like Coffee in the Mornings. Flickr. (accessed Mar 30, 2016). license: https://creativecommons.org/licenses/by-sa/2.0/legalcode