When boiling, baking, frying, roasting, stewing and steaming can be performed by a single cooker, would that be your “one-for-all” weapon in kitchen? A multi-cooker makes your dream come true! The multi-cooker, often seen in Asian and European kitchens, has significantly improved the quality and efficiency of cooking. As an advanced combination of the slow cooker and the pressure cooker, the multi-cooker became more and more popular in modern kitchens. This article describes how a multi-cooker works and explains the details of the internal control system. A multi-cooker controls the temperature and pressure inside the cooker by manipulate the heat flow rate and amount of steam in the cooker in order to properly cook the food. The most fascinating thing about multi-cooker is that it has multiple embedded functions that can be applied to different types of food by simply clicking on these functional bottoms.

Allow commercial talks about how good it is:

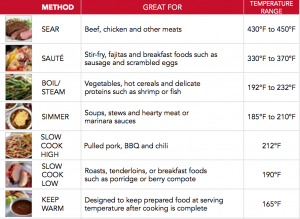

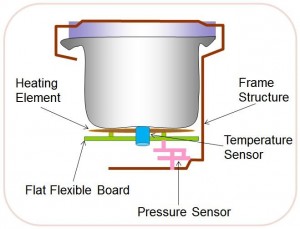

Pressure and temperature of multi-cooker are controlled variables that are significant in this control process. Depending on the property of food (i.e. texture, liquid content and solid content) and the cooking style, setpoints of temperature and pressure under which condition the food can be properly cooked will be experimentally determined. A multi-cooker usually uses a negative feedback loop where temperature and pressure of the cooker can be adjusted to reach setpoints. Typically, the temperature and pressure sensors measure the temperature and pressure in the cooker, and compare measured values with the set points. Then a controller will make decision and take action to adjust the temperature and pressure to approach their setpoints. In order to speed up cooking process, maintain the original flavors of food, it’s important to keep the cooker pressure and temperature in a reasonable range or at a specific value to ensure the cooker working at a relatively high efficiency and avoid potential safety issues.

In order to minimize the difference between cooker temperature and the set point, it’s necessary to adjust the other term called manipulated variables, which are controlled by the controller mentioned above. In the multicooker, the manipulated variables are temperature and pressure of the cooker.

To control the temperature of the cooker, heat flow rate is one of the main manipulated variables which varies in order to minimize the difference between cooker temperature and the set point. As mentioned, the manipulation of heat flow rate by the cooker itself can be achieved by a feedback response provided from a temperature sensor in the cooker. For instance, the best temperature of cooking steak is about 140 degree Fahrenheit, the moisture inside the steak was heated from room temperature to a higher temperature. At the beginning, the heat flow rate transferred in by a thermal panel will be much higher compared to middle or final stage of cooking. Later in the process, the temperature of steak will not be higher than the set point (140 degree Fahrenheit) ideally. Such adjustment can be done by a controller, which in this case, would be a thermal converter that converts electricity to heat. Specifically, An adjustable resistor in a circuit board then manipulates the heat flow rate in order to change the temperature of cooker.

On the other hand, the manipulated variable for the pressure in a cooker is the amount of steam. The pressure of the cooker usually reaches as high as 2 bars. Making the boiling point of liquid (usually water, sometimes wine or broth) in the pot higher than its normal boiling point at atmospheric pressure. A rise of pressure lets the food inside the pot to be cooked at a higher temperature thus the time needed for cooking has shorten by a large amount. This characteristic function is borrowed from pressure cooker where the food will not be smashed because the pressure formed by steam that applies pressure uniformly across the entire cooker. As long as there is some amount of liquid in the cooker, steam can be generated by the heat provided. In order to control this process, a fail-close (ATO) valve works as a controller to automatically adjust the amount of steam in the pot in order to control the cooker pressure. For example, when the pressure inside the cooker is too high compare to its setpoint value, the sensor then will let the valve to be open in order to release some steam.

However, there are some other factors, known as disturbance variables, which may disturb the control system. Disturbance variables have effects on the controlled variables but they cannot be manipulated in the process. In the multi-cooker, the potential disturbances are heat or gas leak from the cooker and disruption of electric current.

Ideally, the current supplied to a multi-cooker is stable and constant. As a result, the cooker can have a stable rate to transfer electrical energy into heat in order to allow its internal system to calculate how much time is needed to achieve the set point. In this case, any changes or disruption on the electric current can negatively affect the efficiency of the cooker and disturb the system. For example, if the amount of electric energy supplied into the cooker is less than the steady state value, it will make multi-cooker to take longer to achieve the desired temperature and pressure. The heat or steam leak from the cooker is also unpredictable and hard to control. Usually designers will try to avoid the leaks, but the possibility of leaks is still present when a cooker has been worked for a long time and some components failed to function properly. Other disturbances include the adjustment on the desired temperature or pressure, known as controlled disturbance. As we change the set points, the time for heating or pressurizing will be changed accordingly. It’s recommended to determine the desired temperature and pressure, which are corresponding to different programs embedded in the multi-cooker before the it starts to work to avoid the controlled disturbance.

Furthermore, the time which takes the cooker to adjust temperature from initial values to setpoints, there is a further time period needed for cook food thoroughly. Such period is set as well as a timer that allows people to see how long it takes for the food to be ready. The length of this period depends on the category of food just like how the temperature and pressure set by experiments. During this period, the cooker will theoretically keep running at the same temperature and pressure. However, the temperature and pressure might be unstable thus same controllers will be working in order to cover the difference.

As an independent household appliance, a multi-cooker saves your money, time and space compared to old styles cooking equipment: all kinds of pans, steamer, slow cooker and oven. Multi-cooker, a universal solution which can replace all of the above appliances, it can even be a fryer when you leave the lid open. Especially, when compared to a slow cooker which cooks food slowly and at low temperatures, it mainly takes you several hours to cook meat in the slow cooker that is an unimaginable luxury for a modern person! The Multi Cooker, in the contrary, cooks twice as fast than a stove. It concerns even the most complicated dishes which require long thermal processing. Also the slow cooker is not recommended for food reheating while it is quick and easy to do so by a multi-cooker.

The feedback-loop multi-cooker owns, enhances its advantage even more, compared to a pressure cooker which can only adjusted by turning on/off stove, has a more advanced adjusting system as a more automatic appliance since temperature and pressure are controlled. Manipulated variables like heat flow rate and amount of steam altered by controllers (resistor and valve), also help the cooker for making delicious cuisine. If there is anything else that can be improvement based on the current model, safety should be considered. A pressure release valve might be involved when electric current suddenly drops to prevent a rapid decrease in pressure. But overall, multi-cooker will be a powerful tool in your kitchen.

Multi cookers are something that has always interested me, but I have never had to chance to use. After reading this article, I am even more curious to try such a product out. I think a product like this is very useful to the average consumer because it is a piece of equipment that can cook many different kinds of food. This can bring down costs of buying different kinds of appliances and other cooking equipment. However, one multi cooker can only cook a certain volume of food at a time so I think it would be wise to sell different sizes to adjust for different sized households. I think this product would be good for those that do not enjoy the art of cooking and are looking for a simple way to prepare meals. This type of device doesn’t allow for much creativity in the kitchen, which is its only downfall for me.

It terms of the description of the control aspect, I agree with everything that was said. The controlled variables are temperature and pressure, the manipulated variable is the heat flow rate, and the disturbance is a gas leak or another type of leak. I don’t believe either heat flow rate or steam flow rate would be harder to control than the other because both require a similar type of sensor to determine if the correct temperature or pressure is reached. However, it also depends how the heat is being supplied and how the steam is being made.

Because the point of this product is to make food quickly but reaching a desired temperature and pressure quickly, a controller that responds quickly is ideal. I would suggest either a P or PID controller for this product. The benefits of the P is it responds quickly and is much cheaper that a PID controller so that can bring down the cost. However, because we are dealing with food and do not want the temperature inside the cooker to get too high about the set point, proportional might not be the best option. The advantages of a PID controller are that it has the quick response of proportional and integral but the derivative control helps counteract the oscillatory aspect of the integral control. Overall, I think this product is very good but I would like to hear a few more parts that could be improved or added in the presentation.

Although the multi-cooker is currently not very popular in the United States, I feel as though we need to jump on board with this new sensation! The diversity of the multi-cooker would enable to concoct a variety of meals. I can envision the general public and myself using this piece of equipment everyday. Not only will you save money, but the amount of time it takes to cook particular recipes will be reduced. Thus, people could merely leave the cooker to bake a dish while doing other things (i.e. chores, shopping). However, I do have a few questions about the functionality of the multi-cooker. For advanced dishes that require a variety of temperatures, can the multi-cooker be used like a thermo-cycler? Also, if a particular dish is not programed into the cooker, can people input the required temperature the dish needs?

Overall, the control schemes described in this blog makes sense. The temperature needs to acquire the desired setpoint of the dish in order to not overcook or burn the meal. At the same time, temperature control will allow the system to not overheat. Overheating could possibly lead to the system burning in flames. Pressure sensors will enable to cooker to cook the meal at faster rates due to the fact that it can achieve pressures higher than atmospheric pressure. Simultaneously, the cooker will not allow the system to become over pressurized, thus reducing chances of the meal or system to erupt. I do agree that the potential disturbances could be disruption in the electric current and leaks in the system. The leaks in the system could cause the temperature and pressure to never achieve the desired set points and thus, the meal could not be cooked thoroughly. One potential disturbance not mentioned in this article is the amount of liquid in the system. The liquid generates steam in the system (i.e. water, broth, sauce). A potential disturbance is if there is not a sufficient amount of liquid in the cooker. Thus, all the liquid can be evaporated quickly. This would also be due to the fact the pressure sensor fails. If the cooker is not able to achieve the desired pressure setpoint, can the cooker automatically shut off?

Based on this article, it appears that only the heat flow rate can be manipulated in order to achieve the desired temperature and pressure setpoints. Thus, some sort of valve controls the flow rate of the heat. In industrial applications, traditionally a PI controller would be utilized. The proportional controller reacts instantaneously while the integral controller corrects what it has seen in previous readings. Together, the PI controller eliminates offset. Tuning parameters can be achieved by recorded data of the temperature. Increasing Kc would enable the overshoot and time response to be decreased. Decreasing tau I would also decrease the time response, but also increase oscillation. Together, the PI controller would be able to react to any fluctuations in temperature that could cause the pressure and temperature setpoints to deviate.

As a food network enthusiast and self-proclaimed food expert, I found this article to be enticing since anything that can cook many different types of food is something that I need to have. I think that the usefulness of this application is rather obvious, since it combines many things that are important to everyone; eating and multi-tasking. It also saves the average person time and money which is definitely important. I also found it interesting that the multicooker can be used for food reheating (an area in which the slow cooker severely lacks) The multicooker, if controlled correctly, would be an excellent addition to any household! In this product, the controlled variables would be the pressure and temperature of the cooker that is needed to cook your meal to perfection. The manipulated variable would be the flow rate of heat/pressure into the cooker. The disturbance variable would be heat/pressure loss to the surroundings. I found it interesting that the author(s) included information about a “controlled disturbance” which involved someone manually changing the temperature/pressure settings to something other than the original desired setpoints. With cooking, overshoot is typically not tolerated since food properties (flavor, texture, etc.) are extremely temperature sensitive. Because of this, I would suggest a PI controller with the proper gain to avoid overshooting the temperature/pressure set points that would allow for a delicious meal. In this application we are talking about food temperature which is very very important to control precisely. Off of that, I’m not sure whether open loop or closed loop tuning should be applied here, but that is something I would be interested to know in the future (say in a hypothetical presentation situation) It makes sense that this application uses a negative feedback system since the temperature and pressure would be explicitly measured inside the cooker, and the manipulated flow rates would change accordingly. This makes the multicooker better than many other kitchen appliances that lack a feedback system, like a microwave as discussed in class. I also liked your idea about having a pressure release valve (fail open!) to avoid the safety issues that can occur under high pressures. All in all I think this blog post is well detailed in terms of process controls, and interesting and useful to the general public, especially those who have a passion for eating like myself. Good job and I am excited to hear more about this product soon!

Overall, I found this product very interesting and useful. I have not personally used a multi-cooker, but I can see how helpful they can be and how much more cost effective they are than buying large appliances for each type of cooking. I this this product would be perfect for someone living in a place with limited space and would allow people to make many different types of meals rather easily.

I believe that the manipulated variable of heat flow rate and amount of steam would be rather easy to change in order to get the proper cooking conditions. I also agree with what was labeled as the controlled variables and what was described as the disturbance variables. My only concern stems from the system becoming over pressurized, which can be rather dangerous. It is important to have something in place to relieve pressure if it becomes too high for the system.

When tuning this device, a PI controller should be used. A plain proportional controller will never reach to optimal temperature and pressure of the system, so it must be used with an integral controller. Because the system only has one input that can only be added and not subtracted overshoot cannot occur. With any overshoot the system may get too hot and pressurized and nothing can fix that as of now. I do not think that a derivative controller is needed for this process, so I would recommend just a PI controller.

Hi Y’all! Great job. I really like the style in which you infused funny pictures along the way. It reminded me of this blog: http://waitbutwhy.com

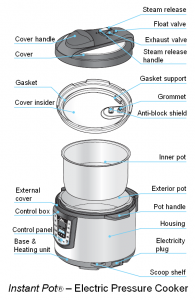

Also, I really liked the introduction and the video. As a very visual person, the more visualizations the better as I was not previously familiar with what a multi cooker actually is. However, as you went into explaining things, I got a little lost along the way and found myself having to track back and re-read some paragraphs. I think that a figure showing the food in the pot and how its cooked would have made things easier to follow since so many different things are going on at once.

You briefly mentioned that leaks are a concern over time and that sometimes things will fail. Knowing the high system pressure and temperatures, I would be interested in hearing some potential safety control mechanisms that you think could benefit one of these cookers. I do like the fact that you added a picture of some safety mechanisms that are considered, but are there anymore that you can think of?

Also, I think it would be very intriguing if you looked at scaling this system. Since you mentioned that many kitchens are moving to using this technology, I would be interested to see if it could be expanded to the size of a conventional oven. This might add some more interesting controls concerns that could be further analyzed.

Lastly, if your control variables are temperature and pressure, I would be interested to know how the disturbances are determined on the choice selection menu. Also, I also would love to hear more about how a control systems can be used to ensure the customizability of the cooking.

I thought this blog post was very well written, I do think it should have some humor to keep it more interesting and maybe a funny title to drag readers in. I had never heard of a multi-cooker so after reading this I actually really want to buy one. It made sense that the controlled variables are pressure and temperature, since that is the primary way food is cooked.

I also thought it was very interesting how the cooking style and setpoints of temperature and pressure under which condition the food can be properly cooked were be experimentally determined. Typically, the temperature and pressure sensors measure the temperature and pressure in the cooker, and compare measured values with the set points. Then a controller will make decision and take action to adjust the temperature and pressure to approach their setpoints.

In order to speed up cooking process, maintain the original flavors of food, it’s important to keep the cooker pressure and temperature in a reasonable range or at a specific value to ensure the cooker working at a relatively high efficiency and avoid potential safety issues. Going off of the safety issues I think it would be important to think of an emergency shutoff procedure. For example, if the pressure or temperature sensor broke without anyone realizing. Then there could be a case where you have a very high temperature or pressure in an enclosed vessel.

One other disturbance that I think may have to be taken in to account in the size of food. Yes, the multi-cooker could come up with a cooking time based on what kind of food is being cooked, however, for example what happens if the pieces of chicken vary in size and each piece takes a different amount of time to fully cook?

Another disturbance I could see is cooking at different altitudes. I know that I go up to the mountains in North Carolina every simmer and you have to adjust oven temperatures and stuff according to the elevation you’re at. However, I think that is a minor thing to think about, and if anything you could just manually override the system (I’m not sure I that’s possible).

Overall, I would say you guys did a really good job and the process what explained really well!!