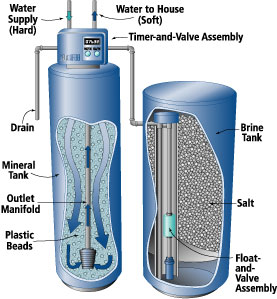

Water softening is a technique that serves to remove the ions that cause water to be hard, in most cases calcium and magnesium ions. Iron ions may also be removed during softening. The best way to soften water is to use a water softener unit and connect it directly to the water supply. A water softener moves hard water containing calcium and magnesium ions into the mineral tank.

The ions exchange with the sodium ions inside the sodium-rich beads in the mineral tank. The sodium ions go into the water, and the beads become saturated with calcium and magnesium, which enters the unit into a 3-phase regenerating cycle. The backwash phase reverses water flow to flush dirt out of the tank. Next, the recharge phase carries the concentrated sodium-rich salt solution from the brine tank through the mineral tank.Sodium collects on the beads, replacing the calcium and magnesium, which go down the drain. Finally, excess brine flushes from the mineral tank and the brine tank refills.

Soft water is important to us because:

- Hard water causes boiler and cooling tower breakdowns.

- Water softeners improve working, and create a longer lifespan of solar heating systems, air conditioning units and other water-based applications.

- Hard water clogs pipes by a higher risk of lime scale deposits. Therefore, hot boilers and tank efficiencies are reduced, increasing the cost of domestic water heating by 15-20%.

- Water softening means expanding the lifespan of household machines, like washers.

Water softeners need control.

How????

Hard water is not a health risk; however softening water adds substantial lifespan to pipes and other water-based machines, which saves money! We seek to control the concentration of magnesium and calcium in the ‘soft’ water output. This range is determined by the Water Quality Association. Thomas Klenck of Popular Mechanics Magazine writes that “Water hardness is measured in grains per gallon (GPG) or milligrams per liter (mg/l, equivalent to parts per million, or ppm). Water up to 1 GPG (or 17.1 mg/l) is considered soft, and water from 60 to 120 GPG is considered moderately hard. A water softener’s effectiveness depends on how hard the incoming water is. Water over 100 GPG may not be completely softened”. The success of a water softener is determined by the decrease in water hardness or the ability to obtain water under the “soft” limit.

There are multiple options for manipulated variables. One option is to control the flow of salt resin between in the brine tank and mineral tank. Studies established that “each cubic foot of resin can effectively remove calcium and magnesium from about 3,200 gallons of hard water, which the Water Quality Association defines as 10 grains per gallon hardness. The process adds about 750 milligrams of sodium to each gallon of water, which the U.S. Food and Drug Administration considers to be in the “low sodium” range for commercially sold beverages” (Wight). It makes sense to control this variable because it affects the quantity of water you can process in a given amount of time based on the hardness of the incoming water. A second manipulated variable would be overall size of the water softener. The larger the tank the more water processed in a time interval and the more surface area necessary in the salt resin for effective conversion of hard water to soft water.

The control in a water softener is found in its recharge methodology. There are three varieties of recharge method found in practice.

Three Types of Control

- Automatic Regenerating System (during recharging, soft water unavailable)

- Electric timer flushes and recharges the system on a regular schedule

- Time clock set by user

- Disadvantages: Generally cost more over time due to regularly scheduled recharge causes no

conservation of salt and water

- Computer Monitoring (reserve resin capacity, some soft water available)

- Computer watches how much water is used.

- When enough water passes through the mineral tank to deplete the beads of sodium, computer triggers regeneration.

- Mechanical Water Meter

- Water meter measures water usage and initiates recharging.

- Mineral tank only recharged when necessary; conserving water, salt and cost.

- Single Resin Tank

- Separate salt tank with fixed capacity to remove ions from water

- Go through a regeneration process each time resin limit is reached

- Disadvantages: Soft water unavailable during recharge

- Separate salt tank with fixed capacity to remove ions from water

- Double Resin Tank

- Separate salt tank monitored by microprocessor meter or electro-mechanical meter

- Advantages: One tank always available for softening, while other recharges; continuous supply of soft water uninterrupted

- Disadvantages: Costs more

- Microprocessor Meter

- Turbine spins as water is consumed and an electronic sensor communicates the rate of spinning to the computer control system.

- Information allows computer to decide when regeneration should be initiated based on water hardness level, which is set by user.

- Electro-Mechanical Meter

- Similar turbine to microprocessor meter, but connected to meter by a cable.

- Once capacity has been reached, electrical motor initiates regeneration.

DISTURBANCES????

During normal use, there will be natural variance in the incoming water hardnesses which requires that your controller be able to change the time spent in the tank and amount of salt resin present to soften the water to within required limits. A water softener could also run out of salt resin within the brine tank demanding refillment by user and thus causing a period without “soft” water.

To account for the natural variance in the incoming water hardness, a feedforward loop could be implemented. A feedforward loop occurs when action and decision tasks are based on the input concentration stream. The incoming water hardness would be measured, sending a signal to the salt resin in the brine tank. Based on whether the incoming water was more or less hard, then a decision to increase or decrease the salt resin flow from the brine tank to the mineral tank would occur as the action.This type of feed forward loop is not used in practice. Another way to account for natural variance in the incoming water hardness would be to implement a feedback loop. A feedback loop occurs when action and decision tasks are based on the output concentration. The outcoming water hardness would be measured and a signal would be sent to the brine tank. The brine tank would make a decision based on the hardness of the outcoming water. The action would occur by increasing or decreasing the amount of salt flowing from the brine tank to the mineral tank coinciding with water that is too hard and water that is too soft.

Now please enjoy this really corny video about how a water softener works:

Current Bibliography:

“Water Softener Use Raises Questions for Septic System Owners.” Center for Watershed Science and Education. University of Wisconsin – Stevens Point, 2011. Web. 13 Mar. 2016. <http://www.uwsp.edu/cnr-ap/watershed/Pages/GWSofteners.aspx>.

Wight, Chuck, PhD. “How Do Water Softeners Work?” Scientific American. Scientific American, 24 Sept. 2001. Web. 13 Mar. 2016. <http://www.scientificamerican.com/article/how-do-water-softeners-wo/>.

Klenck, Thomas. “How It Works: Water Softener.” Popular Mechanics. Popular Mechanics, 01 Aug. 1998. Web. 13 Mar. 2016. <http://www.popularmechanics.com/home/interior-projects/how-to/a150/1275126/>.

“Water Softener Frequently Asked Questions.” Lenntech, 2016. Web. 13 Mar. 2016. <http://www.lenntech.com/processes/softening/faq/water-softener-faq.htm>