|

“Following the light of the Sun, we left the Old World.” -Christopher Columbus |

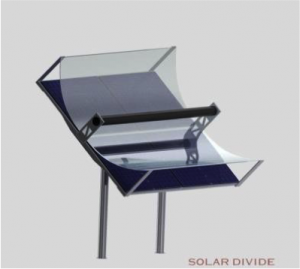

Recently, I’ve been approached by a friend of mine who has started a solar energy company called Solar Divide. They focus on the hybridization of existing solar farms through the combination of solar thermal systems with traditional solar panels. I am interested in joining their team, but before I do so I want to make sure that their current product–the Dual Spectrum Solar Harvester–is a sound investment both scientifically and economically.

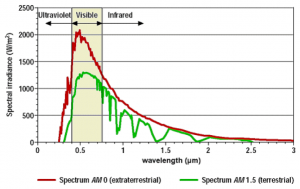

The Dual Spectrum Solar Harvester (DSSH) expands the range over which solar irradiance can be absorbed and converted into electricity. Understanding that photovoltaic cells capture energy from the visible light spectrum, traditional solar panels lose a large portion of the spectrum in the infrared and ultraviolet ranges.

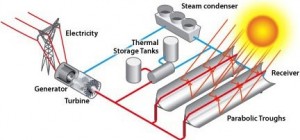

In order capture this lost energy, DSSH replaces the mirrored trough used in traditional concentrated solar power (CSP) systems with a visibly transparent, infrared and ultraviolet reflective trough that could be placed over new or existing photovoltaic solar panels. This allows for the simultaneous collection of photovoltaic and thermal energy.

Understanding all of this, I am left with a few questions and concerns:

- How does this integration of these two technologies (CSP and PV) impact the overall efficiency?

- What can be done to ensure that this system maximizes its energy conversion to electricity?

- What constraints does solar generation face with respect to generation and demand slates?

- Lastly, how does storage of energy impact the system and electrical grid as a whole?

Overall, many of these questions can be analyzed through the understandings of process control. So, let’s think about this…

In terms of process control: What Are Our Significant Variables?

|

Manipulated Variables |

Controlled Variable | Deviation Variables |

| Incident Angle of Paneling |

Electricity Output |

Insolation |

| Energy to Storage/Grid |

Cloud coverage |

|

| Flow Rate of Working Fluid through pipe | Electricity Demand |

With solar panels, the main variable that we are trying maximize is the output of electricity that goes into the power grid. This too is true for concentrated solar thermal systems, however, intermediate controlled variables are necessary to convert the heat into electricity.

But before we talk about power generation, it’s important to understand the demands of the electrical grid. Throughout the day, everyone uses electricity at different magnitudes which poses a disturbance to the generation of that grid (see Figure below).

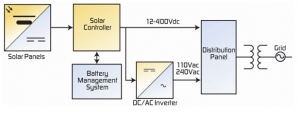

This large flux in energy demand makes solar generation a true process control issue. To account for this, many solar generation plants use certain types of storage or battery management systems in order to have what is know as “dispatchable” energy. In general, the below schematic demonstrates the general layout of a typical photovoltaic solar farm.

However, the product that Solar Divide is attempting to create combines the typical solar farm with the parabolic trough. Even though the issue of electricity demand slate still remains, let’s look into the variables that affect the power generation of CSP.

Since the main source of power–solar radiation–cannot be controlled, the only simple controllable variable on the DSSH then becomes the flow of fluid within the solar receiver. This fluid flow can then be optimized so as to help increase the efficiency of thermal storage and power generation.

The main purpose of a control system on the DSSH would then be to maintain the outlet oil temperature at a desired set point in spite of disturbances from the environment. Since many variables such as (1) the solar irradiance level, (2) the mirror reflectivity, and (3) the inlet oil temperature all can impact the outlet temperature, it is difficult to maintain a desired output with a fixed parameter controller. Since a controller’s response rate and dead time have high oscillations and variation, they must be detuned with low gain and therefore retain sluggish responses in order to compensate for the various environmental factors.

So, you may be wondering…where does one even start to be able to model a system like this?

It’s simple. We start with a balance of energy. (The following equations may be attributed to Camacho et al. and the full citation may be found at the end of this post.)

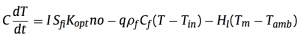

One must first dilineate all of the heat flows in and out of the system. This may be understood to be in the equation below:

- T is the outlet temperature of the field

- Tin is the inlet tem- perature.

- C is the heat capacity of the field

- I is the solar radiation

- Sfi the total reflective surface of the field

- Kopt is the optical efficiency of the mirrors

- no is a parameter taking into account the cosine of the incidence angle between the sun vector and the solar field

- q is the oil flow

- ρf and Cf stand for the density and the specific heat of the fluid respectively

- Hl is the thermal loss coefficient

- Tm is the mean value between inlet and outlet temperature

- Tamb is the ambient temperature.

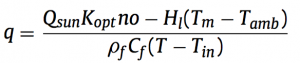

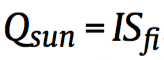

It may seem difficult at first, but in the words of Albert Einstein, “To keep your balance, you must keep moving.” This balance can then be solved to find the equation for the flow rate of the working fluid (the manipulated variable) through the DSSH:

Where,

Where,

Finally the controlled output (production electricity) can then be calculated using the following equation where E stands for the electricity required to pump the working fluid.

![]()

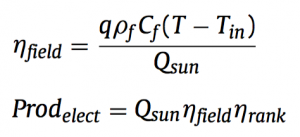

Once experimentally run, the below equations can be used to find the actual production of electricity with the appropriate efficiencies taken into account.

Once an understanding of how this input can affect the output of electricity production, a series of controllers can be put into place so as to ensure that the maximum of output is achieved through the modulation of the flow rate of the working fluid. And if you’re interested in finding out how this is done, please check out my other blog posts!

Please see below for relevant readings:

Xuping Li, Mark Paster, James Stubbins, The dynamics of electricity grid operation with increasing renewables and the path toward maximum renewable deployment, Renewable and Sustainable Energy Reviews, Volume 47, July 2015, Pages 1007-1015. Abstract: This paper presents an overview and analysis of the dynamics and unique impacts of variable renewables on the grid, and identifies the bottleneck problems and solutions associated with renewable integration. Variability issues that concern many are not unique to variable renewables. Grid operators have been dealing with demand variability for over a century. With sufficiently accurate forecast for variable renewables, the grid operators can schedule dispatchable generation and/or storage resources to balance demand and supply on a nearly real-time basis. With state-of-the-art wind forecasting technologies and existing generation resources, wind integration has not caused major operational problems for grid systems with a penetration level of up to 37% during some time intervals. Base load generators operate nearly constantly for days or longer and supply a larger share of the electricity mix than what is proportional to their capacity. This will be a limiting factor for high level variable renewables, if current operation continues. The capability to at least partially follow electricity load should be a key performance measure of non-renewable plants if we are serious about high level variable renewables. Specific policy instruments are recommended to incentivize more flexible plant operation and ensure smooth integration of variable renewables.

Nikolaos S. Thomaidis, Francisco J. Santos-Alamillos, David Pozo-Vázquez, Julio Usaola-García, Optimal management of wind and solar energy resources, Computers & Operations Research, Volume 66, February 2016, Pages 284-291. Abstract: This paper presents a portfolio-based approach to the harvesting of renewable energy (RE) resources. Our examined problem setting considers the possibility of distributing the total available capacity across an array of heterogeneous RE generation technologies (wind and solar power production units) being dispersed over a large geographical area. We formulate the capacity allocation process as a bi-objective optimization problem, in which the decision maker seeks to increase the mean productivity of the entire array while having control on the variability of the aggregate energy supply. Using large-scale optimization techniques, we are able to calculate – to an arbitrary degree of accuracy – the complete set of Pareto-optimal configurations of power plants, which attain the maximum possible energy delivery for a given level of power supply risk. Experimental results from a reference geographical region show that wind and solar resources are largely complementary. We demonstrate how this feature could help energy policy makers to improve the overall reliability of future RE generation in a properly designed risk management framework.

Eduardo F. Camacho, Manuel Berenguel, Antonio J. Gallego, Control of thermal solar energy plants, Journal of Process Control, Volume 24, Issue 2, February 2014, Pages 332-340. Abstract: This work deals with the main control problems found in solar power systems and the solutions proposed in literature. The paper first describes the main solar power technologies, some of the control approaches and then describes the main challenges encountered when controlling solar power systems.