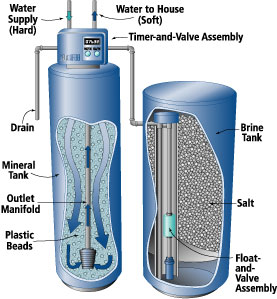

Water softening is a technique that serves to remove the ions that cause water to be hard, in most cases calcium and magnesium ions. Iron ions may also be removed during softening. The best way to soften water is to use a water softener unit and connect it directly to the water supply. A water softener moves hard water containing calcium and magnesium ions into the mineral tank.

The ions exchange with the sodium ions inside the sodium-rich beads in the mineral tank. The sodium ions go into the water, and the beads become saturated with calcium and magnesium, which enters the unit into a 3-phase regenerating cycle. The backwash phase reverses water flow to flush dirt out of the tank. Next, the recharge phase carries the concentrated sodium-rich salt solution from the brine tank through the mineral tank.Sodium collects on the beads, replacing the calcium and magnesium, which go down the drain. Finally, excess brine flushes from the mineral tank and the brine tank refills.

Soft water is important to us because:

- Hard water causes boiler and cooling tower breakdowns.

- Water softeners improve working, and create a longer lifespan of solar heating systems, air conditioning units and other water-based applications.

- Hard water clogs pipes by a higher risk of lime scale deposits. Therefore, hot boilers and tank efficiencies are reduced, increasing the cost of domestic water heating by 15-20%.

- Water softening means expanding the lifespan of household machines, like washers.

Water softeners need control.

How????

Hard water is not a health risk; however softening water adds substantial lifespan to pipes and other water-based machines, which saves money! We seek to control the concentration of magnesium and calcium in the ‘soft’ water output. This range is determined by the Water Quality Association. Thomas Klenck of Popular Mechanics Magazine writes that “Water hardness is measured in grains per gallon (GPG) or milligrams per liter (mg/l, equivalent to parts per million, or ppm). Water up to 1 GPG (or 17.1 mg/l) is considered soft, and water from 60 to 120 GPG is considered moderately hard. A water softener’s effectiveness depends on how hard the incoming water is. Water over 100 GPG may not be completely softened”. The success of a water softener is determined by the decrease in water hardness or the ability to obtain water under the “soft” limit.

There are multiple options for manipulated variables. One option is to control the flow of salt resin between in the brine tank and mineral tank. Studies established that “each cubic foot of resin can effectively remove calcium and magnesium from about 3,200 gallons of hard water, which the Water Quality Association defines as 10 grains per gallon hardness. The process adds about 750 milligrams of sodium to each gallon of water, which the U.S. Food and Drug Administration considers to be in the “low sodium” range for commercially sold beverages” (Wight). It makes sense to control this variable because it affects the quantity of water you can process in a given amount of time based on the hardness of the incoming water. A second manipulated variable would be overall size of the water softener. The larger the tank the more water processed in a time interval and the more surface area necessary in the salt resin for effective conversion of hard water to soft water.

The control in a water softener is found in its recharge methodology. There are three varieties of recharge method found in practice.

Three Types of Control

- Automatic Regenerating System (during recharging, soft water unavailable)

- Electric timer flushes and recharges the system on a regular schedule

- Time clock set by user

- Disadvantages: Generally cost more over time due to regularly scheduled recharge causes no

conservation of salt and water

- Computer Monitoring (reserve resin capacity, some soft water available)

- Computer watches how much water is used.

- When enough water passes through the mineral tank to deplete the beads of sodium, computer triggers regeneration.

- Mechanical Water Meter

- Water meter measures water usage and initiates recharging.

- Mineral tank only recharged when necessary; conserving water, salt and cost.

- Single Resin Tank

- Separate salt tank with fixed capacity to remove ions from water

- Go through a regeneration process each time resin limit is reached

- Disadvantages: Soft water unavailable during recharge

- Separate salt tank with fixed capacity to remove ions from water

- Double Resin Tank

- Separate salt tank monitored by microprocessor meter or electro-mechanical meter

- Advantages: One tank always available for softening, while other recharges; continuous supply of soft water uninterrupted

- Disadvantages: Costs more

- Microprocessor Meter

- Turbine spins as water is consumed and an electronic sensor communicates the rate of spinning to the computer control system.

- Information allows computer to decide when regeneration should be initiated based on water hardness level, which is set by user.

- Electro-Mechanical Meter

- Similar turbine to microprocessor meter, but connected to meter by a cable.

- Once capacity has been reached, electrical motor initiates regeneration.

DISTURBANCES????

During normal use, there will be natural variance in the incoming water hardnesses which requires that your controller be able to change the time spent in the tank and amount of salt resin present to soften the water to within required limits. A water softener could also run out of salt resin within the brine tank demanding refillment by user and thus causing a period without “soft” water.

To account for the natural variance in the incoming water hardness, a feedforward loop could be implemented. A feedforward loop occurs when action and decision tasks are based on the input concentration stream. The incoming water hardness would be measured, sending a signal to the salt resin in the brine tank. Based on whether the incoming water was more or less hard, then a decision to increase or decrease the salt resin flow from the brine tank to the mineral tank would occur as the action.This type of feed forward loop is not used in practice. Another way to account for natural variance in the incoming water hardness would be to implement a feedback loop. A feedback loop occurs when action and decision tasks are based on the output concentration. The outcoming water hardness would be measured and a signal would be sent to the brine tank. The brine tank would make a decision based on the hardness of the outcoming water. The action would occur by increasing or decreasing the amount of salt flowing from the brine tank to the mineral tank coinciding with water that is too hard and water that is too soft.

Now please enjoy this really corny video about how a water softener works:

Current Bibliography:

“Water Softener Use Raises Questions for Septic System Owners.” Center for Watershed Science and Education. University of Wisconsin – Stevens Point, 2011. Web. 13 Mar. 2016. <http://www.uwsp.edu/cnr-ap/watershed/Pages/GWSofteners.aspx>.

Wight, Chuck, PhD. “How Do Water Softeners Work?” Scientific American. Scientific American, 24 Sept. 2001. Web. 13 Mar. 2016. <http://www.scientificamerican.com/article/how-do-water-softeners-wo/>.

Klenck, Thomas. “How It Works: Water Softener.” Popular Mechanics. Popular Mechanics, 01 Aug. 1998. Web. 13 Mar. 2016. <http://www.popularmechanics.com/home/interior-projects/how-to/a150/1275126/>.

“Water Softener Frequently Asked Questions.” Lenntech, 2016. Web. 13 Mar. 2016. <http://www.lenntech.com/processes/softening/faq/water-softener-faq.htm>

Before reading this post, I had no idea about what hard water was, or the harm that it could do to the pipes in a person’s home. This application makes a lot of sense, and appears to be something that could save homeowners, as well as larger companies, a good amount of money overtime. The one thing that I am unclear on is whether this appliance will be used individually per house, or on a larger scale for a water distribution plant. The latter seems to make the most sense, as they would be able to use larger tanks, something that would increase the amount of water softened per process, and would work for a variety of families for a smaller fee. This would make the water softening process more accessible for lower income families, and would decrease overall waste within a region due to replacing worn down or deteriorated pipes.

The control aspects make sense as well, as the amount of water being softened in the tank appears to be something that would be relatively constant depending on the size of the tank. It appears to be more feasible to control the flow of salt resin, as increasing or decreasing the size of the tank mid-process may be more difficult than increasing or decreasing the flow of resin. However, overall, the manipulated variables make sense. In terms of the disturbance variable, it made sense that the hardness of the water in would affect the amount of resin needed in the process. One thing I was unclear on was why the feedforward loop was not used in practice, while the feedback loop was. The logic behind the use of both seemed sound, and in my mind it would make more sense to use them in conjunction, rather than one over the other. In addition, a disturbance variable that may come into effect later in the process would be mineral build-up on the bottom of the tank. A sensor to detect this build-up and determine when the tank needs to be cleaned may be beneficial if this issue would commonly arise.

It doesn’t appear that there would be much noise from either of the disturbance variables, so for the fastest control, I would suggest a PID controller for this water softening process. A PID controller focused on the flow of resin into the system would allow for immediate changes based on the hardness of water moving into the system, and would therefore be both the cheapest and most optimal controller. By monitoring the amount of resin needed for the system closely, there would be minimal overuse of resin – even though the resin is reusable, making the process more green as well. Overall, this seems to be a very efficient process that will save money and make home-owners lives easier!

There is obviously a need for water softeners. It can save you money in the long run by lengthening appliance efficiency and life span. I can see myself using the device. However, I need water straight away, and I do not want to wait for a tank to recharge. I would probably get the mechanical tank that has two tanks, so I can have access to water all the time. The mechanical tank is the more expensive option, so it might deter people from buying a water softener and use other methods such as descaling. Water softening probably has a large commercial benefit as well because it would be expensive to halt production if all the pipes have been severely damaged with iron build up.

The control mostly makes sense. The controlled variable is definitely the softness of the water. The manipulated variable of the amount of resin seems to make sense. I am not sure how easy it is to control this variable or it usually remains static in most water softeners. For disturbances I think the flow rate of water could affect the system. During peak water usages, high flow rate could stop an efficient softening process. I am not entirely sure if a water softener needs the precise control that a feedback/feedforward loop introduces. If the water meets the benchmark for soft water, is it necessary to have it at certain softness? It could just make the product more expensive for no particular benefit. The types of control listed after the variable paragraph does not seem like control schemes. For example, having an electronic timer to recharge is not a way to control the manipulated variable. Perhaps renaming this section could avoid some confusion. Feedforward can help if the time constant of the tank is very large. However, in a home system the volume of the tank is not very large. It could work in an industrial application. The idea of a feedback system does work. The control all together does work and would help the softener do its job.

Water systems are not very dynamic so a PI controller would probably be fine for the system. Derivative would not be necessary as the hardness of the input probably would not change dramatically unless there was some disaster. Proportional would do the majority of the work and then integral control would add some faster response time as well as help reach the set point. Tuning could be done either in an open or closed loop method. Closed loop would probably be easier because once the process is installed you do not want to move pipes around. The process would help save people save money and not worry about pipe failure.

Well thought out and constructed analysis. Most people probably have no idea that their house has a water softener or how it works. As someone who lives in a house with a well and no water softener, I can attest to the benefits of the water softening process on the longevity of faucets, dishwashers, and in particular hot water heaters. These mineral buildups have happened over the course of 30 years and while the valves and devices still work, sometimes they need to be heavily cleaned or scraped, not what the manufacturer intended. Hard water heaters are particularly susceptible to the negative effects of hard water because the buildup on the internal heating elements will prevent good heat transfer and lead to a low effectiveness of the heat exchanging process.

In terms of control, disturbances in the incoming water may not be the biggest concern. City water typically has to pass certain standards in terms of mineral content before it is distributed, so it is unlikely to see any major disturbances there, barring some sort of malfunction or disturbance upstream of the process. The most likely form of disturbance is likely the homeowner forgetting to add salt.

Water softeners are not typically located in a high traffic area, commonly relegated to the basement, out of the way. In many new homes, the homeowners are not very maintenance oriented and may not check the softener as often as they should and it can run out of salt. This means that no matter how hard the controller works to compensate for the “disturbance” it senses, it has no capacity to correct the concentration of the output flow. It could take any length of time for the homeowner to realize this and by then, the system could have been running with unsoftened water for weeks. I did not see mention of what the system would do if it ran out of material with which to soften the water, but maybe some kind of reminder system would be a good way to prevent accidentally rendering the softener useless for extended periods of time.

To me, water softening process has always been treating hard water with Ca(OH)2 and Na2CO3 followed by removing CaCO3 and Mg(OH)2 insoluble precipitates. However, upon reading this blog article, I realized that the household process of treating hard water is a completely different one and that the one I had in mind was mainly for large-scale municipal operations. This makes sense, because having to clear out these precipitates just sounds like an extra chore for the family that no one would volunteer to do anyway.

However, for customers with high blood pressure or other health problems, this device should be used with caution, as water softened by ion exchange with sodium ions results in extra sodium ions being introduced into the water, of which the aforementioned patients should restrict the intake. Alternatives are provided in the market but are generally more expensive.

This brings me into thinking that if people are more aware of the adverse effect of hard water in their daily life and the demand of soft water increase drastically, cities or even states may eventually feel obliged to provide softer water (with a slightly increased cost), thus saving households the trouble of replenishing salt into the brine tank.

Going back to the control aspect of this household appliance. I feel that this article selected reasonable controlled, manipulated, and disturbance variables. Apart from the variables addressed by this article, the flow rate of incoming hard water could also be a manipulated variable or disturbance variable, depending on whether we actually manipulate this variable in real life. I think this variable matters because it will also affect the flow rate of salt required to achieve certain level of water softness. Also if we consider control systems adopted, the recharging rate of sodium ions will also affect the controlled variable, water softness. Therefore, the recharging rate could also be considered a disturbance variable.

PI controller would be more appropriate as derivative control may not be of great use since the natural variance of incoming water hardness is hard to predict.