Technology

A wind turbine is a massive machine that converts wind energy into electricity via a generator. To demonstrate the functionality of these marvels, here are some quantities that describe the functionality of the GE 1.5 MW turbine, one of the most widespread turbines in the nation.

General overview of wind electricity:

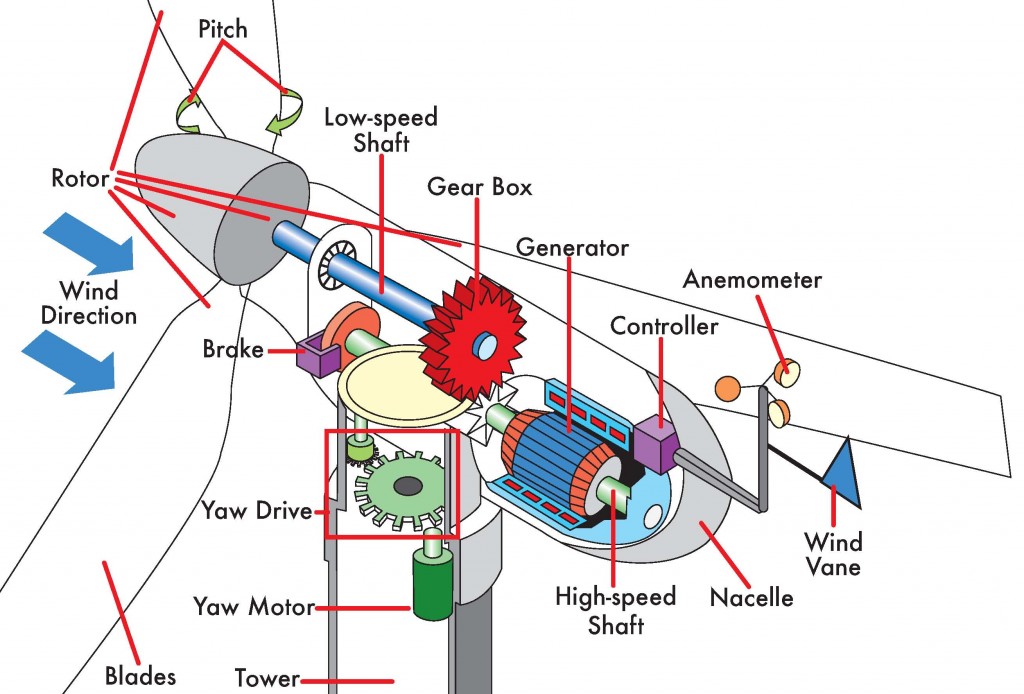

The blades of a GE 1.5MW wind turbine are 116 feet long. These enormous blades turn as wind passes over them, which causes the rotor of the turbine to spin at about 11 to 22 rpm [1]. This “low-speed” shaft then is transmitted through a gearbox, and the output is a “high-speed” shaft rotating at about 1000-1800 rpm* [2]. This high speed shaft rotates the generator coils in order to produce 60 Hertz AC electrical energy.

How fast must the wind be blowing in order for the turbines to function?

There is an anemometer on each turbine to measure the wind speed. When wind speeds reach 8-16 mph*, the turbine begins generating electricity [2]. For the GE 1.5MW turbine, a wind speed of 27 mph produces peak power [1]. At about 55 mph, the turbine shuts down and turns out of the wind to protect from overspeed failures. A brake is equiped to help protect from overspeed as well [2].

How does the wind direction affect performance?

In addition to the anemometer, there is also a wind vane that communicates to the computer the direction of the wind. The computer then commands the yaw motor to turn the turbine into the wind [2].

Doesn’t intermittency of wind affect performance?

This question leads to discussion of the capacity factors of wind turbines. A capacity factor is how much electricity is produced in relation to how much could be produced at maximum performance of the system. According to the Department of Energy, capacity factors have increased from 22% before 1998 to about 35% in 2007. In other words, the average turbine produces about 35% of the energy that it could produce given steady optimal wind conditions year round [3]. A 1.5 MW turbine would provide only about 0.5 MW on average. However, because no fossil fuels go towards electricity generation once the turbine is built and established, this capacity factor does not relate to low efficiencies or wasted fuels.

*general turbines, not specific to GE 1.5MW

Technical Challenges and Feats:

Increasing maximum power output through blade design, material optimization, and generator properties is a constant task in the development of these engineering marvels. Current challenges include:

- Capturing energy across a wide range of wind speeds

- Reducing cost of manufacture by developing “low-speed” generators, eliminating the need for a multiple shaft system and gearbox

- Improving the portability of components, easing the environmental effects of shipping large and heavy parts

Engineering Feats include: [4]

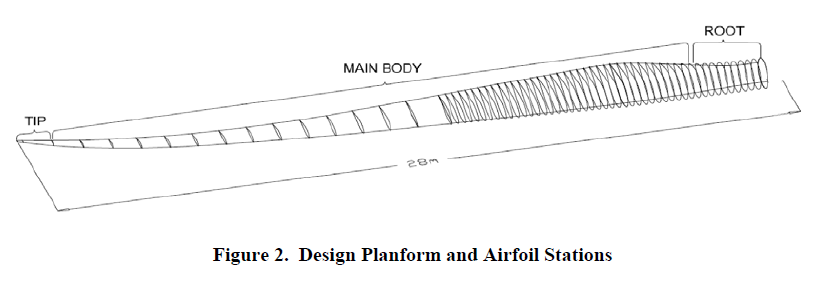

- 1991: Advanced airfoil designs yield 30% more electricity than previous designs, become industry standard

- 2003: Computational Fluid Dynamics software such as NuMaD allow for engineers to accurately predict efficiencies and optimize designs more quickly than before.

- 2004: Single-drive, permanent magnet drivetrain reduces production costs 12.8%. Alongside this, a planetary gearbox and “medium-speed” generator reduce weight and drivetrain costs.

- 2005: “Sweep Twist Adaptive Rotor” (STAR) blade concept introduced, taking advantage of wide range of wind speeds

Current Technological Development:

GE is currently developing turbine blades made from architectural fabrics, as opposed to the conventional fiberglass. With this method, turbine blades could be assembled on site, removing the transportation costs and limitations. GE reports that “could reduce blade costs 25% to 40%”. Because most of the cost of electricity from wind is the capital cost of manufacture, this technology could dramatically affect the future of wind powered electricity [5].

For more information on the GE 1.5 and other GE turbines, click here!

For more information on the GE 1.5 and other turbine models, click here!

For an interactive demonstration of general wind turbine functionality, check out this site!

References

1) “Technical Specs of Common Wind Turbine Models.” Technical Specs of Common Wind Turbine Models [AWEO.org]. Aweo.org, n.d. Web. 27 Apr. 2014. <http://www.aweo.org/windmodels.html>.

2) “How Does a Wind Turbine Work?” Energy.gov. US Department of Energy, n.d. Web. 27 Apr. 2014. <http://energy.gov/eere/wind/how-does-wind-turbine-work>.

3) “Next Generation Wind Technology.” Energy.gov. US Department of Energy, n.d. Web. 03 May 2014. <http://energy.gov/eere/wind/next-generation-wind-technology>.

4) U.S. Department of Energy’s Wind Program—Lasting Impressions. US Department of Energy, 2012. Print.

5) “Fabric Wind Turbine Blade Design Offers Clean Energy.” GE Global Research. GE, n.d. Web. 04 May 2014. <http://www.geglobalresearch.com/innovation/fabric-wind-turbine-blade-design-offers-clean-energy>.

Primary Author: Kevin McHugh

Editor: Mike Bevilacqua