In this section our team discusses the motivation behind the production of our robotic hand mimic device. We discuss the impact that this project can have on society and identify groups that would be interested in the use of it. We present the research that we have done on other projects that have a similar scope and look into if there are any current patents. Please click the links to read more about any of these topics.

Problem Statement

To provide an alternative to direct contact of human hands in the denim industry, by getting rid of humans directly using a sandblaster, and still benefiting from their skilled labor that cannot be replicated by a fully autonomous process.

Functional Goals

Our data glove actuated robotic hand aims mainly to reduce the risk of workers in the denim industry contracting the deadly lung disease known as silicosis. Silicosis results from the inhalation of free crystalline silica, a product found in the air due to the use of sandblasters to give denim the distressed appearance that is often sought after in the fashion industry. Even though the technique of sandblasting denim has been outlawed in many countries around the world, it is still common practice. Arguably the most important functional goal of our proposed robotic hand solution is for the hand to be actuated wirelessly. This would allow for a worker in the denim industry to safely utilize a sandblaster while standing behind a protective glass wall or other protective device while still delivering the same final product. Our group aims to incentivize denim producers around the globe to adopt solutions such as our own to ensure the safety of their employees while providing them with an option to still be able to produce what they currently do.

Concept Generation

By listing topical areas of interest the team came up with the following overlap in interests

- Biology

- Robotics

- Sensors

- Dynamics

- Programming

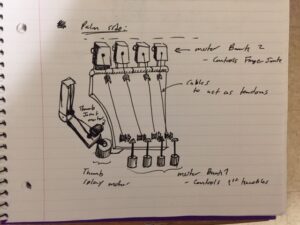

Each team member came up with “conceptual designs” and rough sketches to provide possible projects for the semester. Each project was presented by members of the team and voted on for feasibility and uses in the real market. Of the many projects, the team narrowed down to both the redesigned football helmet and the robotic hand. The final selection was the large robotic hand mimic in which the user would wear a glove outfitted with sensors that will remotely control a robotic hand with a similar hand structure to humans. This selection was made primarily on the fact that the football helmet was already a highly profitable industry and therefor there was not much room for useful or feasible redesign.

—Read More On Concept Generation—

Literature Review

An extensive literature review was carried out by all members of the team to scope the current state of similar technologies that exist today.

–Click Here for Summarized Literature Review–

–Click Here for Full Preliminary Literature Review–

–Click Here for Reference Page–

Patent Search

Although the team does not wish to pursue patents at this time we agree that by understanding and researching patents both still protected under United States federal law, and those entered into the public domain we can best utilize non-protected design concepts and further develop those protected under law while remaining within the guidelines of Title 35 of the United States Code. To read more about United States patent codes and standards and our detailed patent search click the link below.

Broader Impact

Health, Safety, and Welfare:

- Reduce the likelihood of workplace injury of the hand/arm

- Provide employees with a better sense of peace of mind knowing that their job can be less dangerous

- Allows for employers to promote a strong company culture regarding safety when discussing open positions with potential employees

- Reduce the possibility of situations in which employees are exposed to harmful chemicals/dyes

Economic:

- Improved manufacturing technology can lead to new capabilities of designing products and producing them with better quality and precision

- The robotic device can essentially pay for itself by reducing any costs associated with potential or realized workplace injury

- Can make careers in dangerous manufacturing fields more appealing with a new element of safety

- Can increase the demand for skilled labor and education will not accelerate as quickly as the technology can

Environmental Concerns:

- The use of plastics such as PLA (as in nearly any application) can be an environmental concern as plastic materials take a very long time to break down under natural conditions

- The production of any product requires the use of energy which leads to waste products being expelled into the environment

Global, Cultural, and Social:

- Some individuals may be reluctant to accept the product into their field as it furthers the progression towards the automation of many jobs routinely performed by humans

- Could be very beneficial if adopted in modernized non-Western countries where working conditions can be unsafe with very little pay

- Jumpstart more productive conversations regarding workplace safety culture and care for employees

- Improves the safety of textile manufacturing jobs without eliminating the need for the employee

Stakeholders

Our robotic hand is uniquely suited to solve a life threatening practice in the denim industry. In order to create distressed jeans, workers in denim factories utilize sandblasters. Normal operation of a sandblaster would either be in an environment where there is open exposure to air or the sandblaster is enclosed in an enclosure that prevents exposure to silica particles. Repeated exposure to silica particles without proper protective equipment leads to silicosis which ultimately kills the worker after repeated exposures.

Our team has targeted denim factories, specifically ones where worker safety has been neglected, as potential stakeholders for our robotic hand. Given that our hand can be operated remotely, it will take away exposure to silica particles, protecting workers and still creating the distressed jeans that fashion trends demand. Our robotic hand is estimated to come in at a low cost that will be enticing for purchase by denim factories, in order to prevent worker deaths and healthcare costs in the future which would be a much deeper economic burden in the long run than purchasing our remotely operated robotic hand.

Denim factories located in Turkey, Bangladesh, Pakistan, China and Egypt are known to still be using sandblasting techniques. Some of particular interest that are team has identified as examples of the types of manufacturers we are trying to target are: Argon Denims Unlimited, Popular Fabrics Ltd., and Hangzhou Aspiring Textile and Accessories Co. Ltd.