Robotic Hand Actuated by Data Glove

Throughout the 2021-2022 academic year, our team is committed to working to develop a robotic hand that is controlled electronically by someone wearing a glove, with the goal of having a functional prototype at the end of the year. Everyone will work on their specific subsystems and communicate well with each other as we progress throughout the future.

Team Photo!

Back (L to R): Jacob Smith, Margo Mukherjee, Kristin Dingelstedt, Billy Prebola, Ethan Hron, Chad Musilli

Front (L to R): Michael Feng, Austin Barry

It Works!

Project Overview

By combining our team’s interest in robotics, biomechanics, and an overall desire to improve safety in the workplace, we are aiming to design a robotic hand that can perform manufacturing tasks that are potentially hazardous to humans. The specific manufacturing task that our team is taking into consideration is the use of sandblasting in the denim industry to create the distressed look that is often seen in denim products such as jeans. When these workers utilize a sandblaster to complete their task of giving the denim a distressed appearance, they are often exposed to free crystalline silica. When free crystalline silica is inhaled, it can have significant damage on one’s lungs, eventually leading to a condition known as silicosis. Silicosis causes scarring in the lungs which can lead to a serious cough, progressive shortness of breath, and eventually death. By using a data glove to control this robotic hand remotely, the movements of the employee’s hand will be translated to the robotic hand, enabling the work to still be completed while removing the worker from the room full of free crystalline silica. Learn more about how we identified a problem and our iterative design process, in an effort to come up with our project plan to follow for the remainder of the academic year.

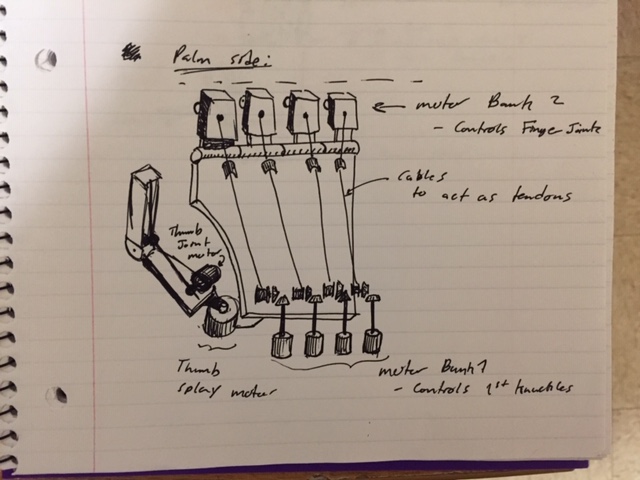

Subsystems

In an effort to work as effectively as possible, we divided the overall project into subsystems. We are tracking the progress of each subsystem using NASA’s Technology Readiness Level method. Click the links below to learn more about each one: