Stakeholders

The main stakeholders for this project are companies that produce denim jeans, as well as the employees who are required to use sandblasters to give the jeans a distressed look. These companies include big names such as Wrangler and Lee. The most important stakeholders that our group is aiming to assist are the employees who are required to work in poor conditions and risk their health in order for these denim products to be produced and sold. If our group were able to market our product to these companies by describing the ways in which it will benefit their employees at a lower cost than a fully automated robot, it would save the lives of many individuals working to provide for themselves and their families.

Our group did not directly engage with any of the aforementioned stakeholders, but if we were to do so, we would begin by reaching out to denim companies and explaining the benefits of our product. Any product which is low in cost and offers tangible health benefits to employees is one that should be appealing to any company that has empathy and their employees’ best interests in mind.

Health, Safety, and Welfare of the Stakeholders:

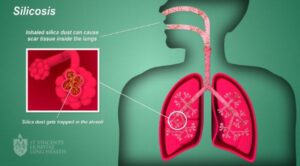

- Sandblasting in the denim industry can cause a deadly lung disease known as silicosis. Our project aims to remove workers from the room in which sandblasting occurs, therefore preventing them from contracting silicosis and having to deal with the associated complications.

- OSHA standard number 1910.1053 Respirable crystalline silica: Employer should implement engineering practices that reduce employee exposure to respirable crystalline silica

- Our project will give employers an easy and inexpensive way to comply with OSHA standard number 1910.1053

- As our robotic hand is controlled wirelessly with the use of the associated data glove, the employee working to create the distressed look that is desired in many pairs of jeans can stand in another room or behind a protective barrier while still completing their work

- Greater protection to the employee afforded by our project can lead to longer lives and better overall health of denim industry workers, ultimately leading to higher levels of happiness and a better sense of wellbeing

Global, Cultural, Social, Environmental, and Economic Aspects:

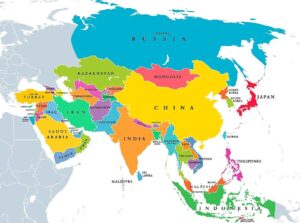

- U.S. and European based denim companies have outsourced much of their production to countries such as Turkey, Bangladesh, China, Egypt, and Pakistan where safety is often not prioritized and workers do not have as many protections/rights. Our project can help to change how workers are treated in these countries if adopted.

- One example of a campaign that has worked to expose the poor working conditions in these countries related to the denim industry is the Clean Clothes Campaign, which could assist us in implementing our project in those settings.

- Helps to redefine a new culture of safety in denim manufacturing that prioritizes worker safety over profits.

- Reduce the amount of otherwise young or healthy people contracting and dying from silicosis.

- Maximize the health of employees to reduce turnover and the likelihood of employees needing to seek medical care.

- Our robotic hand is less expensive than installing a typical contained sandblaster cabinet.

- Our current prototype is made of 3D printed PLA plastic which takes a very long time to decompose. We must be conscious of what material goes into our product and the effect it can have on the environment.

- Manufacturing the device consumes energy and produces waste materials.