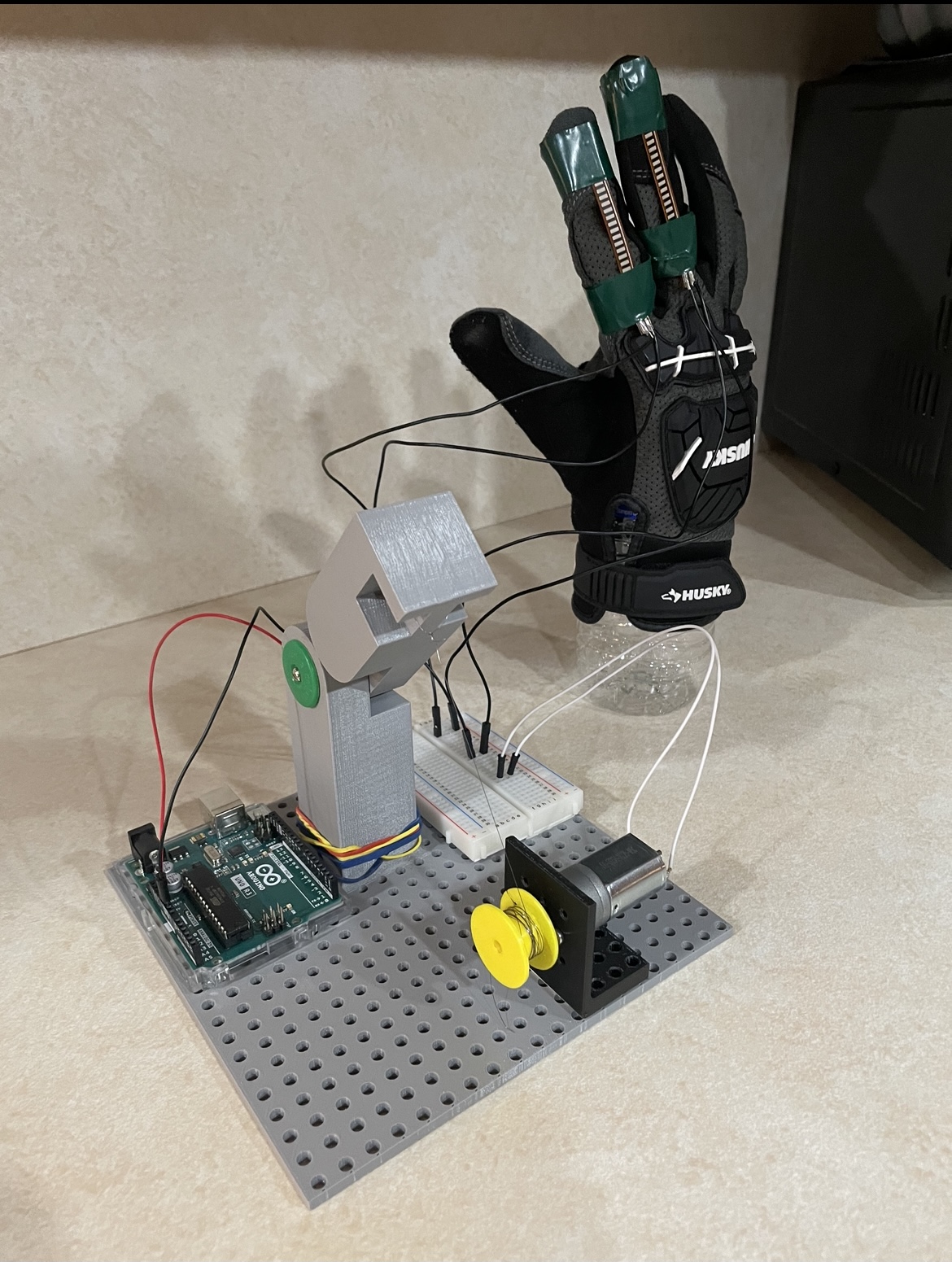

Prototype Features

- Input resistance from flex sensors

- Converted voltage from voltage divider

- 12V motor driven by current “bend angle” of data glove

Up next

- Encoders to implement angular position control

Proof of Concept

- Provides proof that our pinned joint design is effective when operated by a cable

- Proves that torsional bands are enough to pull the join straight when load is released

Current Arduino Logic

const int flexPin = A0; // Pin connected to voltage divider output

int motorPin = 2;

const float Arduino_voltage = 5; // voltage at Ardunio 5V line

const float Resistor_value = 47000.0; // resistor used to create a voltage divider

const float Flat_resistance = 34000; // resistance when flat

const float Bent_resistance = 54000; // resistance at 90 deg

void setup() {

Serial.begin(9600);

pinMode(flexPin, INPUT);

pinMode(motorPin, OUTPUT);

}

void loop() {

int ADCflex = analogRead(flexPin);

float Voltage_flex = ADCflex * Arduino_voltage / 1023.0;

float Resistance_flex = Resistor_value * (Arduino_voltage / Voltage_flex – 1.0);

Serial.println(“Resistance: ” + String(Resistance_flex) + ” ohms”);

// Use the calculated resistance to estimate the sensor’s bend angle:

float angle = map(Resistance_flex, Flat_resistance, Bent_resistance, 0, 90.0);

Serial.println(“Bend: ” + String(angle) + ” degrees”);

Serial.println();

//digitalWrite(motorPin, HIGH);

if (angle > 90) {

digitalWrite(motorPin,HIGH); }

else {

digitalWrite(motorPin,0);

}

delay(500);

}