Most of the following research is from “Historical Pipeline Construction Cost Analysis” by Zhenhua Rui, Paul A. Metz, Doug B. Reynolds, Gang Chen, and Xiyu Zhou of the University of Alaska Fairbanks.

Pipelining is an important and economical method to transport large quantities of oil and natural gas in the petroleum industry. The first pipeline in the USA, two-inch in diameter and over 8 km long, was built in 1865. By 2008, US had a total of 793,285 km of pipelines, among which 224, 260 km was for petroleum product and 548,685 was for natural gas (Rui, 2011).”

To understand pipeline construction costs, pipeline data — such as pipeline diameters, lengths, capacity, year of completion, and location — are analyzed. The PennEast Pipeline’s dimensions are expected to be as follows:

- Diameter of 36 inches, which is 3 feet

- Length of 108 miles, which is 570,240 feet [1]

- Capacity of 4,030,789 cubic feet [2]

- Completed in year 2017

- Located in the Northeast [3]

To further understand pipeline construction costs, the following cost components cost components are analyzed:

- Material costs: the cost of line pipe, pipeline coating, and cathodic protection

- Labor: the cost of pipeline construction labor

- Miscellaneous: a composite cost of surveying, engineering, supervision, contingencies, telecommunications equipment, freight, taxes, allowances for funds used during construction, administration and overhead, and regulatory fees

- Right of Way (ROW): the cost of ROW and allowances for damages

- Total: the sum of material, labor, miscellaneous, and ROW costs

Distribution and share data

In this section, PennEast Pipeline distribution, share and cost data has been compared to those of 412 pipelines recorded between 1992 and 2008 in the Oil and Gas [4].

Diameter

Diameters of the 412 pipelines recorded between 1992 and 2008 range from 4 inches to 48 inches and value of diameters is even. From low values to high, data shows that values of pipeline diameter are left-skewed. For example, there are only 24 (5.8% of the total) pipelines with diameters between 4 inches and 10 inches, while 218 (52.9% of the total) pipelines with diameter between 30-inch and 48-inch, like the 36-inch PennEast Pipeline. Data being left-skewed indicates that more larger-diameter pipelines have been constructed than smaller-diameter pipelines in the last two-decades. At 36 inches, PennEast Pipeline would be a larger-diameter pipeline, which is more common.

Length

Lengths of the 412 pipelines recorded between 1992 and 2008 range from 0.01 miles to 713 miles. The distribution is right-skewed. From low to high, data shows that values of pipeline lengths are right-skewed. For example, there are 258 (62.6% of the total) pipelines in the 0 to 10 mile group, and 65 pipelines in the 10 to 20 mile group, but on 30 (7.3% of the total) of pipelines are longer than 60 miles, like the 108-mile PennEast Pipeline. Data being right-skewed indicates that the majority of reported pipelines are shorter pipelines. At 108 miles, PennEast Pipeline would be longer, which is less common.

Capacity

Capacities of the 412 pipelines recorded between 1992 and 2008 range from 13,270 cubic feet to 5,215,691,727 cubic feet. Capacities range from 13,270 cubic feet to 5,215,691,727 cubic feet, and the average pipeline capacity is 86,511,969 cubic feet with standard deviation of 15,840,088 cubic feet. The distribution of pipeline capacity is right-skewed. For example, there are 59.29% of pipelines’ capacities less than 30,000,000 cubic feet, and only 3.64 of pipelines’ capacities larger than 400,000,000 cubic feet. At 4,030,789 cubic feet, PennEast pipeline would be smaller, which is more common.

Location

There are 157 pipelines located in the Northeast region, which is 40% of US pipelines for the region with the greatest number of pipelines. In the Northeast, Pennsylvania is the state with the most pipelines at 72.5, which is 17.60% of US pipelines and 46.18% of Northeast pipelines. The fewest number of pipelines was located in the Southwest region, which had 30 pipelines, 7.5% of US pipelines. The number of pipelines in other regions is between 48. As stated earlier, PennEast Pipeline is located in the Northeast region, in the state of Pennsylvania, which is the most common location for a pipeline.

PennEast Pipeline would be located in the Northeast region. With a diameter of 36 inches, a length of 108 miles, and a location in the NorthEast, the diameter of PennEast Pipeline is in the range of 34 to 48 inches, and the length is in the range of 60 to 160 miles. For pipelines located in the Northeast, material costs tend to be 24% of total. In addition, for pipelines in the mentioned ranges of diameter and length,material costs tend to be 34% and 31%, respectively. Therefore, in terms of its location, diameter, and length, the material cost of PennEast Pipeline would be between 24% and 34% of its total construction cost.

Regarding material cost trends, values of length and diameter that are higher tend to be associated with higher material cost percentages. To reiterate, PennEast Pipeline would be a larger in terms of diameter and length, meaning material cost percentages would be higher. On the other hand, the Northeast region is associated with the lowest material unit cost percentage, and PennEast Pipeline would be located in the Northeast.

Labor

For all 412 pipelines, labor cost on average is highest. The average unit cost in labor was $24 per cubic feet, 40% of total average unit cost. This cost tended to fluctuate widely with miscellaneous cost.

Given the 3 groups in terms of diameter, length, and location, associated with the PennEast Pipeline, associated labor cost percentages are 40%, 39%, and 43%. This means labor costs for PennEast Pipeline would range from 39% to 43% of total pipeline construction cost. As the length of pipelines increase in construction, labor cost percentages tend to decrease. The Northeast, where the PennEast Pipeline would be constructed, is associated with the highest labor cost.

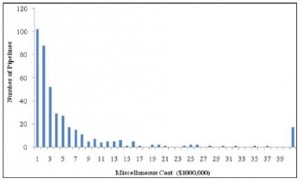

Miscellaneous

For all 412 pipelines, miscellaneous cost is second lowest. The average unit cost in miscellaneous was $14 per cubic feet, 23% of total average unit cost. This cost tended to fluctuate widely with labor cost.

Given the 3 groups in terms of diameter, length, and location, associated with the PennEast Pipeline, associated miscellaneous cost percentages are 20%, 23%, and 27%. This means the labor cost of the PennEast Pipeline would be between 20% and 27% of total pipeline construction cost. As the diameter or length of pipelines increase in construction, miscellaneous cost percentages tend to decrease. The Northeast, where the PennEast Pipeline would be constructed, is associated with the second highest labor cost.