Overview

Our first project was the washing station. This space will be used to clean a wide variety of vegetables and pack them for either storage or distribution.

Fig 1. Current Wash Station

Image shows the current washing station at Hacket, with a section for packing and drying next to the sinks and spigot. Image taken by Konstantinos Voiklis.

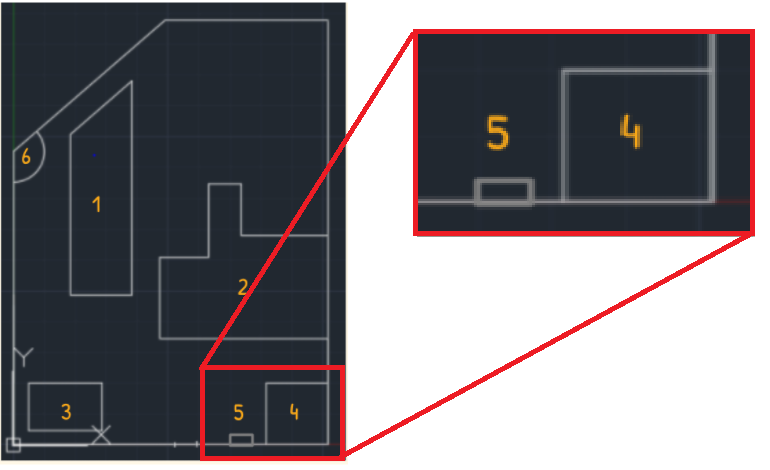

Fig 2. Footprint of Current Wash Station

Image shows the location and footprint of the current wash station (labeled 5) next to the larger storage area (labeled 4) within Lower Hackett Farm on the lower right corner of the property.

Above is a picture of the current wash station and storage area. It’s currently placed approximately sixteen feet to the right of the entrance and eight feet left from the coolbot. It occupies a ten-foot by four-foot footprint. From right to left, there is the loading zone directly next to the table where freshly picked vegetables are dropped off, the washing tank where the vegetables are individually cleaned, the drying rack where the wet vegetables are able to drip dry sitting on a wire table, and the packing station where the vegetables are loaded into storage bins. From there, they move into the coolbot to be stored until distribution.

Ms. Wilcha expressed two primary technical desires for our update: that the station repurposes components of the existing wash station, and that the new wash station should occupy a similar footprint to the existing one. In addition, due to the variety of vegetables grown, the wash station needed to accommodate the variety of ways different vegetables will need to be washed. Because of the nature of small community gardens, the solution needed to require relatively low-tech solutions.

With these primary constraints in mind, research as to the most effective solution began. Penn State states that the primary intentions of an effective wash station are to reduce the chances of foodborne illnesses harming a consumer or bacteria spoiling food, resulting in waste (Gorgo-Gourovitch et al., 2021). The University of Arizona outlines the best way to achieve these goals is by “using vigorous [washing] methods without brushes,” as they increase the chances of blights and bacterias being transferred from one infected vegetable to another (Mpanga et al., 2020). There are a number of ways of producing vigor when washing, and with the need to accommodate a variety of vegetables, a couple of different methods would need to be utilized. Generally speaking, there are two broad washing categories which vegetables can be classified into: scrub vegetables and soak vegetables. Scrub vegetables include all root vegetables like carrots, radishes, beets, and scallions, but also vegetables like tomatoes, peppers, and cucumbers which are cleaned more effectively via scrubbing rather than soaking. Soak vegetables on the other hand consist of loose-leaf greens like lettuce, kale, and chard. These vegetables are “grown close to the ground [and are exposed to] a variety of systems,” meaning they have a high risk of contamination (Chamberlin, 2021). Root vegetables with caked-on soil require high-pressure agitation while leaf vegetables require a gentler, less targeted cleanse. To this end, two primary systems are necessary.

This proposed system is easily transferable to Hackett’s current setup. The scrub station can be mounted on the post sitting directly behind the current sink, providing a place for the water to drain. The soak station is small enough that it can fit to the right of the current table in front of where the hose is wrapped. It avoids being in the way of the hose as when not in use, it can easily be broken down into its primary components and be stored underneath the table. As desired by Ms. Wilcha, the vast majority of the current station is maintained. The untouched table sections serve the drying and packing needs very well, and modifications to those systems aren’t needed.

Scrub Station

Technical Breakdown

The scrub station is composed of a variety of cheap and accessible hardware components. The design takes direct inspiration from longtime farmer Jesse Frost of Rough Draft Farm. Despite its name, there is no physical scrubbing occurring. Rather, the design consists of a wide-angle spray nozzle that produces a cascade which “scrubs” the vegetables with high-pressure water. The water is controlled via a foot pedal, allowing one’s hands to remain free for vegetable handling. The nozzle provides a powerful directed spray capable of cleaning a wide variety of root vegetables very quickly. In all, the design consists of seven individual components, the vast majority of which are converting the hose threading to a pipe threading and directing the spray downward, perpendicular to the washing surface. This design was chosen for its simplicity and for its ease of implementation in the current system. This design calls for a grated table (table with holes), allowing one to rest the vegetables on the surface while allowing the water to escape without running across the other vegetables. The current wash station already has such a surface, and the nozzle can be mounted as needed, making it a simple yet effective solution.

Starting from the bottom of the structure and moving up, the scrub station consists of a foot-powered water valve with a ½” pipe threaded (NPT) inlets and outlets. In order to accommodate the standard ¾” hose threads (GHT, as compared to NPT), a ½” female NPT to ¾” female GHT is necessary. In order to move the water upwards to the nozzle, Hackett will need a length of cross-linked polyethylene (PEX), a high-strength tubing solution, connected via ½” female NPT to ¾” male PEX barb. As the water flows up approaching the nozzle, the PEX will be converted back into NPT via a ¾” male PEX barb to ½” female NPT 90° elbow. From there, the elbow leads out parallel to the ground into ½” to ¼” male NPT Adapter, into a ¼” female NPT 90° elbow, and finally into the ¼” male NPT flat spray nozzle. A trade-off of opting for PEX is that it requires the use of clamps to ensure a water-tight seal and a specialty cutter to cut it to length. We believe this trade-off is justified by its durability. Ultimately, PEX can be substituted for ¾” irrigation tubing, but the adjoining fittings would need to be appropriately changed to suit the new tubing.

Fig 3a. Nozzle Portion of Scrub Station

Image shows a hose connected to a high-pressure nozzle that is spraying the root ends of scallions. Image source: No-Till Growers.

Fig 3b. Pedal Portion of Scrub Station

Image shows the pedal of the scrub station which is pressed by the farmers foot to control the water flow to the nozzle. Images source: No-Till Growers.

Economic Breakdown

As mentioned, the scrub station is composed almost entirely of relatively common hardware store fittings. Upkeep costs are of little concern as the parts are durable, but also cheap in case of failure. So long as the system is partially disassembled to allow water to drain from the system so as to not crack pieces since water expands when frozen, it should be more than durable to survive freezing temperatures. Below is a table outlining the line-item costs. They are accurate as of publication and are sourced primarily from McMaster-Carr, with the foot pedal being from Amazon and the tubing and its fittings being from Home Depot.

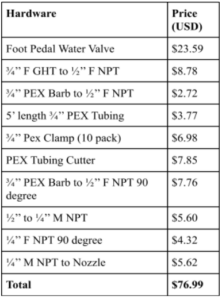

Table 1. Scrub Station Pricing

Prices sourced from The Home Depot, Amazon, and McMaster-Carr. Accurate as of December 16, 2021.

Soak Station

Technical Breakdown

The soak station, as mentioned, required a different approach to producing the agitation needed to effectively clean this different group of vegetables. A concept that has been popularized within the small-scale farming community is the ‘greens bubbler’. An air pump blows air into the bottom of a tub of water, producing bubbles that provide a general agitation. With the number of leaves greens provide, washing them individually would take hours. Bubblers provide a way to wash large quantities of greens very quickly. Agricultural Engineering technician Andrew Chamberlin of UVM outlines the basic components and composition of greens bubblers in his article Building a Better Greens Bubbler. There he breaks down the three primary components of a greens bubbler: the tank, the air distribution system, and the air pump. The air distribution system is generally constructed out of PVC tubing with holes drilled throughout its length, forming bubbles when air is passed through it while submerged, meaning the system is highly customizable to suit the size of the container and volume of produce you are working with. Chamberlin also provides case studies from different farms, breaking down their exact systems and farmer feedback on how those systems have worked. We have based our design specifications largely on that feedback. The soak station will consist of fewer individual parts than the scrub station, consisting of a tub, PVC tubing, and an air pump. Given the feedback Chamberlin received, a 100-gallon stock tank is a widely available size that would be more than adequate to sustain a farm of Hackett’s size and output. To pump the air, a variety of blowers exist in the 1 horsepower, 120-volt range, typical for a 100-gallon tank. The PVC distribution system can be designed to suit the tank, but will generally consist of basic shapes such as lengths, elbows, splitters, and caps of PVC depending on the orientation. We are hesitant to provide detailed specifications as the availability of specific tanks and blowers can fluctuate. Below is a short video showing a bubbler washing lettuce mid-process. It’s meant to demonstrate the kind of agitation the system produces.

(Notice: Video has sound and may play loudly if volume is on.)

Video 1. Soak Station in Action

Video shows lettuce mix being washed in a similar soak station at Chanticleer Acres in Litchfield, CT. Video taken by Konstantinos Voiklis.

One necessary addition to the greens station which is more difficult to build is the spinner, which dries the greens after bubbling using centrifugal force (much like a home-sized salad-spinner, but larger). As such, a spinner will need to be purchased as well. Johnnys Seeds, one of the largest US seed and farm equipment distributors, offers a variety of spinner sizes on its website. For Hackett’s output, a 2.5 gallon spinner should be suitable. The list price is $161.00 (Johnnys Seeds, 2021).

Fig 4. Assorted Soak Station Designs

Images show three examples of soak stations that employ the air pump/PVC combination in a large tub. Images from SARE, Keith Wilkes, and UVM respectively.

Fig 5. Johnny’s Seeds 2.5 Gal Spinner

Image shows a greens spinner, with the outer spinning container next to the inner strainer container. Image from Johnny’s Seeds.

The specific placement of the soak station and its accessories, although desired to remain in relatively the same place, is flexible to an extent. Wash stations require good drainage of the wastewater or you risk creating a patch of mud under your workplace, increasing both the mess of already dirty farm equipment and the chance of food contamination. The area surrounding the wash pack and adjoining storage is all covered in a substantial layer of gravel, making the specific placement flexible. As it stands, from a workflow perspective, placing it in front of the hose to the right of the wash station’s table is optimal due to its relative position to the beds and storage locations. We felt it necessary to mention that, due to the highly personalized nature of different farming systems and individual practices, that the final positioning is flexible within certain floorplan bounds and workflow perspectives.

Economic Breakdown

The soak station has fewer total parts than the scrub station but ultimately has a higher startup cost. Because we aren’t making a precise recommendation of the PVC air distribution system and PVC comes in standardized lengths and segments, we are providing cost estimates using an approximate total parts list which should provide plenty of flexibility in terms of the final construction. The PVC tubing and stock tank are both very durable and the need to replace a component within a five-year window is exceedingly unlikely. The blower on the other hand is an electrical component and is exposed to the elements, meaning the probability that it breaks is much higher than its plastic counterparts. Although it is waterproof, exposure to water in freezing temperatures or long-term exposure to temperature fluctuations will significantly decrease its lifespan. With proper care and storage, it should last three-plus years.

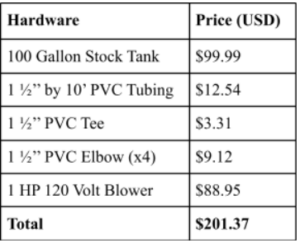

Table 2. Soak Station Pricing

Prices sourced from The Home Depot and Amazon. Accurate as of December 16, 2021.

The total cost of the wash station updates comes to $439.36. Given the typical community garden operates on a yearly budget of “between $2,500 to $5,000,” this is not an insignificant cost (Surls, 2001). However, two factors mitigate this concern. First, because our intention is to provide a final plan to Ms. Wilcha that she can then submit to the City of Easton for funding, the hope is that these projects can be covered outside of the general budget the farm will usually operate under. Second, because our project is intended to help increase the productivity and output of the farm, it’s not unreasonable to assume that this increased output would lead to an increase in the farm’s budget as more people would be benefitting from the program, spurring Easton legislators to fund the farm more.

Click here to go to our Bed Arrangement Breakdown.