< Previous Section (Political Context)

Next Section (Economic Analysis) >

This section of the report will focus on the technical accounting of the different elements needed to bring our project proposal into fruition. The technical piece of our capstone project includes amplifying the values and goals of LaFarm by incorporating functional artwork to the new greenhouse structure that is scheduled to be built in the coming years. Our capstone group has consulted numerous members of the Lafayette community including Lisa Miskelly, Jim Toia, Mary Wilford-Hunt, and Delicia Nahman along with other resources and previous EGRS reports to further advance and complete the contents of the technical analysis for this project.

Background:

When we first met with Lisa Miskelly to talk about incorporating dynamic installations into the landscape of LaFarm, she mentioned that any artistic feature should be relatively low cost, low maintenance, and take up as little space as possible. She had also mentioned that earlier this year members of LaFarm and the greater Lafayette community had begun searching for funding, finalizing a design, and curating a timeline for a greenhouse to be built on the property (“2021: Here we Grow”, 2021). As previously stated in our report, the need for a greenhouse at LaFarm has been growing over the past couple years. The addition of a greenhouse would allow Lisa and her staff to start the growing season earlier in the spring and continue later in the fall. Furthermore, the greenhouse would provide additional opportunities for student farmers to work closely with early phase seedlings and conduct their own research (Drago et al., 2017). Considering where the greenhouse proposal currently sits, we thought that incorporating functional and dynamic art into the greenhouse structure would allow us to successfully meet Lisa’s criteria and further amplify the main goals and values of LaFarm.

Greenhouse Specifications:

According to Lafayette College’s Sustainability Director Delicia Nahman, the college is looking to construct a greenhouse that is designed to be 30 x 48 feet at the northwest corner of the property. These dimensions were chosen because it is the largest standard size which can reliably be ventilated passively without a powered airing system (Beyer et al., 2015). Nahman said that there are currently two greenhouse designs that the college is considering building, both by Rimol Greenhouse Systems. The features and benefits of each of the designs can be found in the table below along with pictures of each greenhouse design:

|

Greenhouse Design Option #1- Nor’Easter

|

Greenhouse Design Option #2- Matterhorn

|

| · Available in the size the college is looking for.

· 4’ or 6’ bow spacing with bows being 1.90”, 13 ga. galvanized steel tubing. · There is a truss assembly with every bow resulting in unmatched strength. · 5 purlins that connect to the bows using a cross connector which prevents unnecessary drilling into the bow. · Truss support system allows for addition purlin pipe to be hung for hanging baskets. · Wind bracing kits including with all greenhouses. · Engineering meets International Building Codes (IBC). · Additional custom options available for roof, walls, sides, ventilation, and heating systems. |

· Available in the size the college is looking for.

· Super easy to assemble beginning with starter column installation. 4” starter column is used for setting the lower section of the column, then the remaining length of column is spliced for an easy installation. · Columns have base plates and are 4” x 4”, 13 ga. galvanized steel. · Non-welded truss is quality assurance when assembled and allows for easy shipping and assembly. · Trusses designed to meet snow and wind load requirements of the Lehigh Valley area. · Extra purlins near gutter provide additional snow load support in Northern climates which prevents premature wear on polycarbonate and eliminates leaking. · Large 12 ga. steel gutter allows easy access to roof and downspouts are designed to be located anywhere in gutter for maximum flexibility. · Engineering meets International Building Codes (IBC). |

Table 1. The different features and benefits of each of the proposed greenhouse designs (Rimol).

Figure 1. Greenhouse Design Option #1- Nor’Easter (Rimol).

Figure 2. Greenhouse Design Option #2- Matterhorn (Rimol).

The orientation of the greenhouse was determined after a EGRS capstone group in 2017 conducted research on where the optimal placement of the structure would be and found that this orientation would allow for maximum thermal efficiency. The capstone report also mentions that this orientation would allow the prevailing northerly wind to aid in air circulation of the structure. A current picture of the footprint of LaFarm can be found below along with a rendering of where the greenhouse is currently being planned to be placed.

Figure 3. A current rendering of the current footprint of LaFarm (Google Earth).

Figure 4. A rendering of LaFarm with the proposed area for the greenhouse highlighted in red (Google Earth).

Our Proposal:

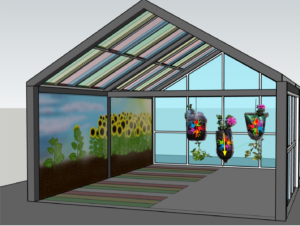

The specific design features our team is proposing to incorporate into the greenhouse include installing dye-sensitized solar cells (DSSCs) on the roof of the structure, hanging upside down planters made from recycled materials from the trusses, and painting two murals on the side walls. The dye-sensitized solar panels along with the upside-down planters would work in tandem to illustrate the heating process of the greenhouse while the mural aims to foster community and collaboration between members of the Lafayette community. We also made sure that all our design features would be able to be implanted in either greenhouse structure.

Figure 5. A rendering of the artistic features our team is proposing to incorporate into the structure of the greenhouse (Google SketchUp/ WCCEO/ Authors).

Our capstone group decided to focus on proposing these elements because they accentuate and encompass all four of LaFarm’s overarching goals and values. While the greenhouse itself is focused on the food production element of the farm, our project would tie in circular integration by having art students at Lafayette design the upside-down planters. Furthermore, it would also provide an opportunity for students who don’t necessarily have an interest in farming to feel like they are able to have a part in the space. In addition, this plan promotes community engagement by educating Lafayette students, visiting K-12 school groups, and other members of the greater Easton community how greenhouses operate and invites them to further engage with the farm. While some students learn best from reading textbooks or having teachers explain certain topics, our functional art project will provide another way from students to better understand and grasp the concepts of how greenhouses and plants are able to convert light into heat by visually displaying it and letting students interact with some of the pieces. Lisa Miskelly also mentioned that she has been trying to engage with students from the greater Easton area to learn more about science, health, and their community and we believe that our functional art design would promote educational activities for them. Furthermore, using recycled materials to build the upside-down planters and environmentally friendly materials to paint along the walls of the greenhouse would further LaFarm’s initiative of promoting environmental sustainability.

Dye-Sensitized Solar Cells

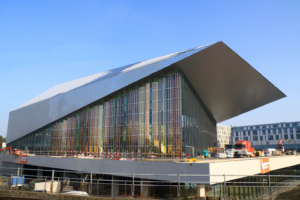

Our suggestion to install dye-sensitized solar cells into the roof of the greenhouse takes inspiration from the facade of the SwissTech Convention Center in Ecublens, Vaud (Switzerland). In 2013, 1,400 solar modules of 35-by-50-centimeter photovoltaic panels were mounted to help regulate the temperature inside the building, produce renewable electricity, and add artistic value to the center (Romande Energie / Mediacom, 2013). The design was created by Swiss artists Daniel Schaefer and Catherine Bolle and were manufactured by a Swiss company called Solaronix( Romande Energie / Mediacom, 2013). According to an article published by the Swiss Federal Institute of Technology, Lausanne, the dye-sensitized solar panels have a total surface area of 300 m2 and are able to produce up to 8,000 kilowatt hours (kWh) per year (Barraud, 2012).

Figure 6. A picture of the SwissTech Convention Center in Ecublens, Vaud (Switzerland) where the facade of dye-sensitized solar cells can be clearly seen (Solaronix).

Figure 7. A view from inside of the SwissTech Convention Center that shows the facade of dye-sensitized solar cells (SwissTech Convention Center and Northern District).

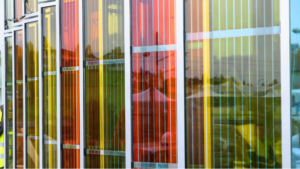

Figure 8. A close-up view of the dye-sensitized solar cells that have been integrated onto the facade of the SwissTech Convention Center (EPFL / Alain Herzog).

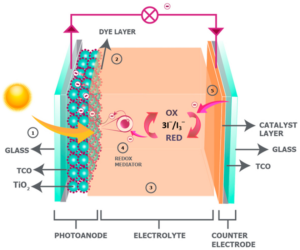

Originally invented by Professor Michael Grätzel and Dr. Brian C. O’Regan of the Swiss Federal Institute of Technology, Lausanne in 1991, dye-sensitized solar cells were created to provide a less expensive and complex alternative to other photovoltaic cells (Jacoby, 2016). Dye-sensitized solar cells, also known as Grätzel cells, are able to produce electricity through an artificial process that is very similar to photosynthesis. The process begins when sunlight passes through a glass layer and the dye within the cells absorbs photons from the sun and uses this energy to excite elections (Jacoby, 2016). These electrons are then injected and flow through a layer of Titanium Dioxide (TiO2) back towards the transparent electrode. The electrons then flow back into the chemical electrolyte in the cell after passing through a counter electrode (Jacoby, 2016). The electrical current is produced by the moment of the electrons and can be harvested into a rechargeable battery, supercapacitor, or other electrical device (Jacoby, 2016).

Figure 9. A model showing the inner-workings of how a dye-sensitized solar panels is able to convert sunlight into usable energy (Iftikhar et al., 2019).

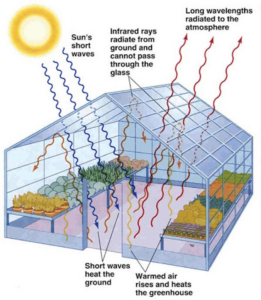

The main reason our project team is proposing to install dye-sensitized solar cells on the roof of the greenhouse is to illustrate and visually represent the inner heating and cooling process of the structure. A greenhouse functions by trapping the heat energy plants and other objects inside the structure release after absorbing sunlight (Riley, 2021). Windows, vents, and fans can also help release heat from the greenhouse if it gets too hot (Riley, 2021). This process can be shown in the diagram below:

Figure 10. The process of how a greenhouse using the sun’s energy for heating and cooling (Oumari).

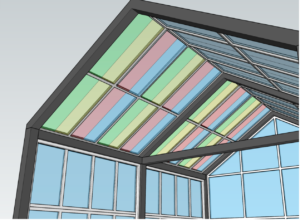

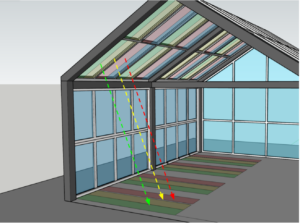

By installing dye-sensitized solar cells on the roof of the greenhouse, visitors would be able to visibly see how the direct path of the sun rays enter the structure. The dye from the solar panels would project the colors onto the ground so visitors could see the waves heat the ground. Considering the technical aspects and specifications of both greenhouse structures, roughly 267.6 square meters (m2) of dye-sensitized solar cells would be needed to cover both sides of the roof. Being as dye-sensitized solar cells can “achieve more than 11% energy conversion allied to good performance under any atmospheric condition and low irradiance”, at least 713.6 kilowatt hours (kWh) would be produced per year through these panels (Gonçalves et al., 2008). That also leaves more than enough (around 89%) of the energy from the sun for the plants and crops inside the greenhouse to absorb and generate energy and heat from (Stauffer, 2018). Renderings of our proposal to install dye-sensitized solar cells on the roof of the greenhouse can be seen below:

Figure 11. A rendering of the dye-sensitized solar cells being installed onto the roof of the greenhouse (Google SketchUp).

Figure 12. A rendering that shows the path of light as it comes from the sun and goes through the dye-sensitized solar cells (Google SketchUp).

Upside Down Planters

Working in tandem with the dye-sensitized solar cells, hanging upside-down planters from the trusses of the structure would further illustrate the heating and cooling process of the greenhouse. Our project team decided to propose the implementation of upside-down gardening infrastructure to LaFarm because of the numerous benefits associated with this technique. Upside-down gardening allows for an increase in growing space, efficiently delivers water and nutrients to plants by gravity, significantly eliminates the chance of pests, fungus, and weeds from soiling crops, and allows for greater air circulation and sunlight exposure (Murphy, 2010). Furthermore, these planters can be made with recycled materials such as plastic soda bottles, milk jugs, or five-gallon plastic water bottle as seen below (Murphy, 2010):

Figure 13. Upside down planters made from recycled five-gallon plastic water bottles (WCCEO).

According to Rimol’s website, both greenhouse proposals can support the weight of hanging baskets or crop support systems (“Matterhorn”, n.d. and “Nor’Easter”, n.d.). The National Grants Management Association (NGMA) recommends that loads hanging from trusses of greenhouse structures should not exceed a maximum of 15 pounds/square foot (psf) which would allow for the planters to weight up to 21,600 pounds in total, since the greenhouse is planned to roughly be 1,440 square feet (ft2) (Bartok, 2017). Typically, upside down planters are around 50 pounds when they are filled with soil and our team believes that installing 20 planters would be a great number (“1846 – Upside Down Tomatoes – Do They Work?”, n.d.). Additional testing would need to be performed to see where the planters should hang and make sure the structure remains sturdy, but this number of planters would not overcrowd the space and allow other small plants or decorations to hang from the trusses as well. Industrial grade hardware would also need to be purchased in order to mount the planters to the greenhouse. Our team would suggest purchasing at least 20 heavy duty spring links and around 100 feet of strong chain to secure and hold the weight of the planters. That amount of chain would allow each planter to hang 5 feet down from the truss.

Although our project team came up with a preliminary design that incorporates the handprints of Lafayette community members and the path the heat energy takes within the greenhouse (shown below), Lisa Miskelly had mentioned that she wants to offer more opportunities for Lafayette students to get involved with LaFarm in capacities other than farming. We believe having art students design and create these planters would be a great way to introduce a new cohort of community members to LaFarm. However, arrows demonstrating how the heat from the plants and other objects get trapped within the structure is essential to the design in order to further illustrate how a greenhouse functions.

Figure 14. Upside down planters made from recycled five-gallon plastic water bottles overlaid with our design idea (WCCEO/ Google SketchUp).

Painting materials would also need to be purchased for students to execute their designs onto the planters made of recycled materials. Our team recommends using a water-based acrylic spray paint on the planters because of its adhesion, resistance, and environmentally friendly properties (“Evolution Acrylic 10.9 oz. Gloss Anthracite Grey, Water Based Spray”, n.d.).

Murals

The final component of the functional art is the murals painted on the sides of the greenhouse. These murals seek to enhance the artistic value of the greenhouse, while not interfering with its functionality. Murals have long been a staple of community art, and the large sides of the greenhouse are an ideal canvas.

Figure 14. Side one of the greenhouse

Figure 15. Side two of the greenhouse

One side of the greenhouse will depict the growing process of a sunflower. By illustrating this process, the mural brings both educational and artistic value to the sides of the greenhouse. It also emphasizes the personal nature of a small farm, where individual care and attention is given to the plants. The other side of the greenhouse aims to reflect the values of community and sustainability. On the left side, members of the community are depicted participating in farming and growing produce. On the right side, there are a series of solar panels. These panels not only show the solar power utilized by LaFarm, they also echo the sustainable nature of both the farm and Lafayette community. In addition, these solar panels drawback to the dye-sensitized solar cells, alluding to the function of the cells and bringing all of the greenhouse components together.

Figure 16. Krylon paint in royal purple

In order to maintain the functionality of the greenhouse, these murals will be painted using Krylon stained glass paint. Stained glass paint gives any glass material the look and color of stained glass. It allows color to be applied to the glass without compromising the transparency. In addition, the paint is applied like spray paint, so it is ideal for covering large surface areas like the walls of the greenhouse. The paint will be applied to the inside of the greenhouse, to protect the art from weather, and preserve the murals as long as possible. The paint is available in 7 different colors, which is ideal for creating the colorful murals.