Technical Analysis

Previous Page: Social Context

Greenhouses have been in use for hundreds of years, and particularly in America, industrial standards have arisen. The express purpose of a greenhouse is to create a space that can be kept hotter than outdoors while still being open to sunlight. This is achieved through a structure made of translucent materials, originally glass but now mostly plastics, which will help keep light in and keep cold out (Coleman, 2009). As with any technology, there are problems in this system. The two primary problems became that as greenhouses got bigger, without ventilation pests and diseases become unmanageable and that modern agriculture demands more heat in greenhouses than is possible without added heating.

So over time expensive and fragile glass greenhouses were replaced with cheaper designs using acrylics, and then polycarbonate when acrylic was deemed to vulnerable to fire. Even cheaper, more temporary greenhouses made of simple frames and polyethylene sheets proliferated, for creating spaces that could support varying levels of micro-climate control. Passive ventilation was supplemented with large, powered ventilation units, and new passive ventilation technologies like ridgevents and roll-up sides were invented. And supplemental heat in the form of radiators, electric heating mats, and forced air systems are now used to create spaces in cold climates which can support growing produce originally intended for warm climates, either by starting the seeds to be moved outside later or by growing the plants entirely indoors.

These new standard designs require a good deal of energy, and have a good deal of variation, but that variability follows a formula. That formula takes into account the shape, size, material, and location of the greenhouse as well as how it is ventilated and heated. These different aspects of the design impact how much energy the greenhouse requires, how it can be used, how durable it is, what other equipment will be necessary, how much it will cost and how it needs to be maintained. Below, we provide a table summary of these different parts of each design, a detailed explanation of each aspect, and then an analysis of each design. The issue of cost is explored in depth in the Economic Analysis

Overview

| Hoophouse | Gothic Greenhouse | A-Frame Greenhouse | |

| Frame | Gothic Frame | Gothic Frame | A-Frame |

| Size | 30×48 | 30×96 | 30×96 |

| Side Material | Single Layer Polyethelyne, maximum light penetration | Double Layer Polyethelyne, keeps in more heat | Polycarbonate, durable, permanent |

| Location | Over good soil for growing, among rows | Close to the field, but not on it, hopefully accessible by road | Close to field, not on it, accessible by road |

| Ventilation | End Wall Passive Ventilation | Powered Ventilation system, roll up sides, ridgevent | Powered Ventilation system, ridgevent |

| Heating | Nothing added | Electric Blankets | Forced Air, electric blankets |

| Energy | None | Blankets, Ventilation | Heating, Ventilation |

| Use Potential | Extending in ground season by providing heat over certain rows | Space for starting seeds in the beginning of the season and for growing in ground at the end | Place for starting seeds, growing in pots, hydroponics, etc. |

| Durability | Single layer poly needs to be replaced on average every 3 years | Double Layer Poly needs to be replaced on average every 5-7 years | Polycarbonate on average needs to be replaced after about 10 years, can be replaced piece by piece |

| Extra Equipment | None | Benches/tables | Benches/tables, pots, hydroponics infrastructure in the future |

| Notes | – | – | On a concrete foundation, a permanent structure. Would require shades and shade control |

| Maintenance | Polyethylene checked for tears when it is used, little/no special training required | Ventilation and heating mats need to be checked daily, training required in how to operate and understand these systems | Ventilation and heating systems need to be checked daily, training required in how to operate and understand these systems |

Explanation

This section draws on information gathered through personal interactions with LaFarm Manager Sarah Edmonds, Bud Peltz from Griffin Greenhouse Supply, and USDA Agent Tianna DuPont. (For more information and additional support see Cohen, 2014; Coleman, 1989; Coleman, 2009; Kuria & Titus, 2012; Ponce et al., 2015; and Upson, 2014).

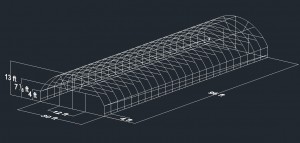

Frame Shape. The overall shape of a greenhouse can be described as having 2 end walls and a tubular section between them. The shape of the frame is the shape of the tube.

The Gothic Frame shape is necessary for polyethylene greenhouses in USDA Zone 6 because the Gothic frame sheds snow, and can therefore stand up to the snow load in our climate. The A-Frame allows for more moving and growing room, and is better for a permanent structure which will be able to stand up to the snow regardless. Additionally, to make the A-Frame greenhouse design permanent, it would have to go on a concrete foundation like a normal building, unlike the other designs which would just go on the ground.

Size. The floor size of the greenhouse. 30×96 is the largest standard size, allowing for the most room. For greenhouses without a powered ventilation system, the length can be no longer than 3 times the width (depending on wind patterns in the climate of the location) or wind will not pass through, which would cause problems with pests and diseases. Therefore we would limit the hoophouse size to 30×48, which is the largest standard size which can reliably be ventilated passively.

Side Material. For cheap/temporary greenhouses, polyethylene is the standard material because it blocks little light and traps a lot of heat, while being inexpensive. A single layer of poly will block little light but keep in less heat than double layer poly, which naturally does block out more sun. Double layer also has an envelope of air between the layers which keeps in more heat, and lasts longer. In USDA zone 6, the trade off between heat and sunlight filtration in going from a single layer to a double layer is worthwhile, because more heat is more important than more sunlight. Still, in order to inflate the air envelope, powered ventilation is necessary.

For permanent greenhouses, there are more options for wall material. The classic is glass, but glass is so expensive to construct and repair that despite its advantages, most companies will not even build glass greenhouses any more. The most used materials now are acrylic and polycarbonate. Acrylic is more expensive and lasts longer, but is not fire safe, making it a dangerous option. Polycarbonate will not last as long, but is as sturdy as acrylic, keeps in about as much heat and sun, is cheaper and does not burn. Additionally, permanent greenhouse materials generally keep in heat significantly better than polyethylene.

Ventilation. Ventilation is required in greenhouses to get pests out, to regulate temperatures, and to prevent buildup of disease. In order for the greenhouse to be controlled enough to risk starting seeds to grow into transplants, when plants are especially vulnerable to pests and disease, powered ventilation is necessary. This powered ventilation takes the form of large fan units which force air through the entire greenhouse, and sometimes additional fans in the middle of the greenhouse to move more air.

For temporary greenhouses, which are not used during the winter, roll up sides are generally used to allow for extra ventilation A) during the hottest months and B) during the winter, to allow the weather to sterilize the soil. These involve a mechanism for rolling up the polyethylene sides.

Methods of passive ventilation increase control of the temperature as well. Ridge vents are mechanisms for opening a ridge along the length of the greenhouse which creates a type of heat flow which will not instantly cool down soil (the most important part to have hot) but allows for heat to leave the greenhouse.

Heating. Extra heating in the greenhouse allows the greenhouse to be used even further out of season. This is extremely useful for starting seeds. Despite that, most greenhouses usually have some form of radiator to heat them which is wasteful, and heats the greenhouse uniformly, burning fuel. For a greenhouse that is being used to start seed, a less wasteful option for heating is the use of heating mats which can be set to an individual temperature for each bench, allowing for the best temperature for germination for each type of seed. These do use more electricity than a forced-air system, but do not use fuel, and can be used individually and maintained separately.

Since the permanent greenhouse can potentially be used for things like vertical growing, winter growing, keeping potted trees in during the winter, or other long term projects of the like, having a forced-air system that can allow for climate control may become necessary. This raises the question of fuel. There is the possibility of installing a geothermal heating unit, but this would While there are some designs of forced air systems where air or water is heated by the sun and circulate through the greenhouse, designing a truly sustainable heating system for a permanent greenhouse beyond the electric blankets would be an entire project in itself.

Energy Requirements. The addition of powered ventilation units, heating mats, and forced air heating systems would require power for these systems. On an average day, using the ventilation system and heating mats of either the Gothic or A-Frame Designs could easily require around 90kWh of power. Using the forced air system instead of the mats would require closer to 60kWh, but a forced air heating system would require additional fuel for heating which, as mentioned above, would require a whole research study into being sustainable. Currently, the solar array at Metzgar with 16 panes on 2 panels, generates at most 16kWh a day on sunny days (during the fall), and on especially cloudy days generates closer to 1kWh. This means in order to be sustainably powered, we would need some 90 panes on 12 solar panels, batteries for storing the energy, and hopefully wind turbines to continue power generation on cloudier days. (Based on data gathered from https://www.mypvpower.com/dashboard/750 and calculations done based on the electrical requirements of the greenhouses, detailed in the quotes given to us by Griffin Greenhouse Supply) (Peltz, 2014a; Peltz, 2014b). A Microsoft Excel spreadsheet which shows our calculations is located here: Calculating Energy Requirements for Greenhouses.

The Electrical Systems for the Gothic Greenhouse are 4 Wadsworth Vent Motors, 2 Exhaust Fan Motors, and 48 20″ by 48″ electric heating matts. The Electrical Systems for the A-Frame Greenhouse are 4 Wadsworth Vent Motors, 2 Exhaust Fan Motors, 2 sets of Motorized Shutters, and 2 Modine Heating Units and/or the same 48 electric heating matts.

Durability. The different siding materials have different levels of vulnerability. A single layer of polyethylene is vulnerable to damage like hail and wind storms, and is hard to repair (the damage is generally ignored until it is severe enough to be replaced.) Under normal conditions, polyethylene needs to be replaced every 3 years because of damage.

For reasons including extra durability due to the air envelope and a higher threshold of damage to actually interfere with the operations of the greenhouse, double layered polyethylene needs to be replaced on average after 5-7 years, depending on the amount of damage. Replacing the double layer poly is a more complicated process than the single as well.

Polycarbonate is a sturdy material and fares much better against storm-related and everyday damage. On average, polycarbonate will last around 10 years. Additionally, since polycarbonate greenhouses are made up of panes of polycarbonate, individual panes can be replaced as needed, which can disperse cost over time. Polycarbonate is now the standard for permanent greenhouses because of how fragile and expensive glass is, and because it is cheaper than, and does not catch fire like acrylic siding does.

Use Potential. Because of the limitations of heat and ventilation, as outlined in their respective sections, the hoophouse’s use would be limited to growing plants in the ground. Transplants in a hoophouse can be put in when it would be too cold outside, and plants living in a greenhouse can last longer into the season because they can survive past the outside frost dates, which offers potential increase in growing potential. Furthermore, research can be done in the hoophouse to analyze how these plants interact with the unique microclimate created in the hoophouse.

The Gothic greenhouse can be used for starting seed because of the added ventilation. This means being able to teach students how to start their own seed, cutting out costs of buying transplants and/or transportation to and from an offsite greenhouse for starting seed. Starting seed would require “greenhouse benches” which are essentially screen tables that are designed so that they will not hold disease or create space for pests. Additionally, in the Fall, when seed starting is done, this greenhouse can be used for anything the hoophouse could, and more effectively due to the extra ventilation.

Because of the permanence and the amount of control over the microclimate of the A-Frame design, not only can it be used for starting seeds more effectively than the Gothic design, in the future it can also be the site for experimentation with hydroponics or vertical gardening, it can be used for growing plants in the winter, and plants like citrus trees can be grown in large pots and moved between the greenhouse and outdoors depending on the season. Additionally, the extra climate control makes experimentation with chemistry, heat flow, biology, and soil science much higher.

Analysis

Hoophouse. The hoophouse design is an extremely simple physical structure: several sets of metal pipes and wooden end-walls with a polyethylene covering. Industry standard versions of this design can be ordered from multiple sources such as Nolt’s Produce Supplies, and can be constructed by Garden Manager Sarah Edmonds and a few workers or volunteers in a single day. It would be placed in a location where LaFarm could grow food in the ground: away from the southeast corner of the farm which is prone to flooding, either over some of the rows that are currently used for growing or in a space outside the current fence where the soil is healthy if LaFarm expands. Then the hoophouse will be used by Sarah to grow earlier in the season, with vegetables like tomatoes or fennel, and potentially later into the season with crops like spinach. It would not require constant maintenance and therefore would not require someone to watch it every day, but after it became majorly damaged it would require a new polyethylene sheet, probably around once every 3 years.

It would also not be a place that could be used to start seeds, it would only be able to extend the season of in ground plants, increasing production and altering when things could be harvested. It could also be a space for experimentation, especially around the topic of how much extra production can result from such a design.

Gothic Greenhouse. The Gothic greenhouse is a standard design that is indispensable for most vegetable growers. The frame and end walls are the same as for the hoophouse, but this design would be twice as long and it would have two layers of polyethylene with an inflated envelope of air between to keep in more heat. Double layered polyethylene is more durable than single layered and would not need to be replaced nearly as often (on average, 5-7 years of life.) It would have a ridge vent, roll-up sides, and large ventilation units which would keep pests and disease out better than it would be possible to with a passive design, which would make it safe enough for starting seeds. This requires benches and heat. The heat will be delivered by heating blankets because these can be powered by electricity alone (meaning they could be powered by solar panels and wind turbines without a fuel source.)

To supply this energy sustainably, there would need to be many more solar panels out at LaFarm (potentially over 5 times more,) and hopefully more wind turbines, but there would be no fuel requirement. This system could potentially be constructed by LaFarm workers, but is more likely to be constructed by a contractor. Installing additional solar panels and wind turbines would also require contracting. Furthermore, the heating and ventilation systems would need to be checked daily for failure, meaning that there would have to be training done for someone to take check and maintain the greenhouse daily.

This design would be used to start seeds in the Spring and early summer, and could be used to grow in ground during the end of the season. This means it would still need to be located somewhere there is good soil, like the hoophouse. Because it can start seeds, LaFarm would be able to use this space to expand connections with the local community, giving space to local farmers or others wanting to start seed. Additionally, it could be used by students to experiment with biology, chemistry, geology, etc. as it pertained to agriculture.

A-Frame Greenhouse. The A-Frame design is highly advanced, and beyond the industry standard as it is a permanent structure. It would require a concrete foundation and a metal frame, with polycarbonate walls. The polycarbonate panels have an average life of around a decade, but can also be replaced one as a time as needed. It would have powered ventilation just like the Gothic design, as well as a ridge vent (no roll-up sides, as you cannot roll-up polycarbonate.) This would make it safe enough for starting seeds. It would also have a forced-air heating system which could be used if a sustainable fuel source were found, and electric blankets just like the Gothic greenhouse. Because the permanent design keeps in heat much better than either of the temporary ones (which is a great advantage in the cold months,) it is necessary to have shutters which can be controlled by a motor to help regulate the temperature of the greenhouse by blocking the sun when necessary (during the hottest days of summer.) Because these shutters use very little energy, the only major addition of energy between the Gothic design and this one is the forced-air system, which uses less energy than the heating mats which would not be used concurrently. This means that the expansion of energy production infrastructure at LaFarm would be the same for this design as for the Gothic design.

Since this design would allow for even more climate control than the Gothic design, the A-Frame greenhouse also offers extra space for local community to grow inside, and offers much higher potential for students to do scientific research inside. But, because it has a concrete floor it can no longer be used for growing in the ground, and would therefore be better to place in a location with less fertile land. It would also be good to have this design located somewhere with road access (especially if it would be being used for community programs.) The best location for this in reference to LaFarm’s current potential land would be near the micro-apiary, near the Metzgar maintenance building, but depending on how LaFarm expands a different location may become the better choice.

These different designs require different processes for funding, construction, and maintenance, which are explored next in the policy analysis.

Next Page: Policy Analysis

Previous Page: Social Context