A Gas Turbine Combined-Cycle (GTCC) power plant utilizes natural gas to generate electricity. The gas is burned in the first cycle, to produce both exhaust heat and electricity. The heat is then used in a second cycle to produce electricity.

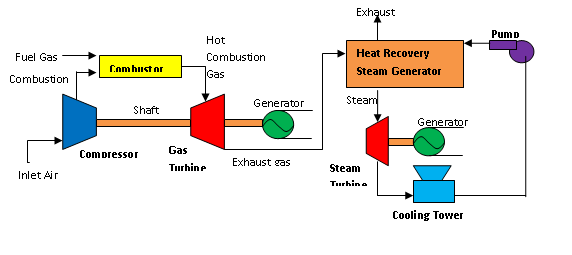

As seen in the diagram, the first cycle of a GTCC power plant resembles a traditional natural gas power plant. Inlet air is compressed and sent to the combustor, where it is mixed with natural gas and then burned. The resultant hot combustion gas enters a gas turbine and is expanded turning the turbine blades. The spinning turbine blades drive a generator shaft which translates the mechanical energy due to rotation to usable energy. This energy is pushed through to the grid and allocated where it is needed. This first process creates a large amount of excess heat.

A GTCC power plant differs from a traditional gas plant because the hot exhaust gas is not rejected from the plant as waste. Instead, this gas travels to a heat recovery steam generator, where it is used to boil water into steam. Only then does the exhaust leave the plant. The steam is then used to turn a second turbine and power a second generator. The steam is then cooled back to water in a cooling tower and pumped back through the heat recovery steam generator.

Within each of the generators, a spinning magnet is surrounded by copper coils. As the magnet spins withing the copper coils it generates a magnetic field. The magnetic field charges the electrons withing the copper wire and produces electricity.

The importance of a GTCC power plant lies in its improved efficiency when compared to a traditional natural gas or coal-burning power plant. We have made the following assumptions to calculate the efficiency and fuel use of each plant.

1. We are using a 250 MW power plant for each type of plant, and each plant must provide the same amount of electricity.

2. This plant operates at full capacity for 4000 hours per year. This is a little less than half of a year, which we estimate to cover peak demands. Demand increases based on several factors. Seasonality accounts for how much energy is being used for appliances, heating and air conditioning ranging over the year. Natural gas reserves dictate the price of gas and how much will be allocated by power companies. Finally, there are miscellaneous factors that cannot be predicted.

3. The Energy Information Association (EIA) has data for average annual heat rates for fossil fuels. We used these values and other information in our calculations and have assumed them to be accurate.

We used the efficiency for a GTCC plant of 60%. This value was provided to us by Edward S. Rubin’s book, Introduction to Engineering and the Environment. For comparison, a power plant using heated natural gas to drive a turbine has an efficiency of 42.4%, while a power plant using coal has an efficiency of 32.5%.

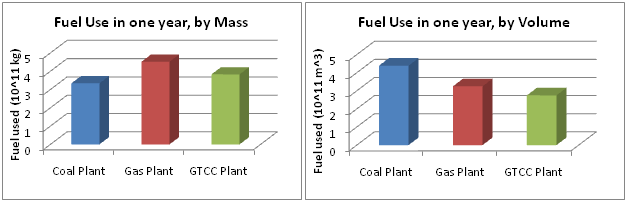

We also compared fuel use by mass and by volume. As shown by the graphic above, the GTCC plant uses the least amount of fuel by volume and only slightly more fuel than coal by mass. A GTCC plant can therefore use less fuel than other plants to produce the same amount of electricity.

Resources:

“How Combined Cycle Works.”ge-flexability.com. General Electric Company. Web. 13 April 2014

Rubin, Edward, and Cliff Davidson. Introduction to Engineering and the Environment. NewYork: McGraw, 2001. Print.

Supple, D. Units and Conversions Fact Sheet. MIT Energy Club, 2007. Print.

Table 8.1. Average Operating Heat Rate for Selected Energy Sources. U.S. Energy Information Administration, 3 February 2014. Web. Accessed 12 April 2014.

What is the Efficiency of different types of Power Plants? U.S. Energy Information Administration, 3 February 2014. Web. Accessed 12 April 2014.

Primary Author: Eric Gallant

Editor and Secondary Author: Justin Sandler