Meet our team!

Hi! My name is Connor Port. I’m a freshman from Frederick, Maryland looking to study Mechanical Engineering. I am in the outdoors club, cycling club, and equestrian team here at Lafayette. I’m excited to share our group project that we have been working on for this class!

Hi! My name is Avery LeTourneau. I’m a freshman from Grand Rapids, Michigan and am a member of the swim team. I’m looking to major in mechanical engineering and am excited to share the this project that we’ve been working on for the past few weeks!

My name is Julia Greeley, and I’m from Southampton, NJ. I’m a track and field athlete and prospective civil engineering major at Lafayette College. Can’t wait to share all that my group members and I have learned during this module!

My name is Abby Hammel, I am from Simsbury, Connecticut, and am a junior here at Lafayette. I am a Policy Studies major and am on the rowing team. I have loved working with this group for the past seven weeks and am very excited to present our final design with the class.

Discuss the problem you chose to solve. What motivates you? How did you identify it?

In order to identify our problem, we first worked to find our target audience.

Identifying Our Target Audience-

Connor Port – 09/06/2021

We organized our target audiences into groups, illustrated by sticky notes. The different color dots were to distinguish each group member’s individual values/ideas about the different audiences. The red dots were for the audiences each group member thought was the most unique, blue were for the ones they cared about the most, yellow was the most accessible to interview, and green was the most impactful. Our group consensus was that Cashiers would be the easiest group to interview, and would have problems that we could design an impactful solution for in the span of the class. Cashiers are also essential in the grocery store experience, and if we could somehow improve the way that they work, we could inadvertently improve other aspects of the grocery store experience.

Image: Color-coded sticky note illustration of plausible target audiences

We then came up with a plan to interview the target audience that we decided upon: Cashiers

ES 101 Cashier Interview Script

Using the questions above, we interviewed cashiers in our local area and received the following responses:

- (Response #1) Demographics: female, ≈19 years old

Best part of the job: Recognizing customers, getting to know customers’ needs, helping people, getting to hear about customers’ lives

Plausible change: Better up-to-date systems to prevent customers from becoming impatient, i.e. when items need to be input manually

Least favorite item: Anything not scannable/ any item requiring manual input

2. (Response #2) Demographics: female, ≈17 years old

Best part of the job: Coming across a customer who makes a positive impact by being kind

Plausible change: A faster, better bagging system/ a second person to bag so that the line doesn’t get backed up

Least favorite item: Alcohol

3. (Response #3) Demographics: male, ≈20s

Best part of the job: Building relationships with customers

Plausible change: Organization/diminishing the long lines

Least favorite item: clothes, especially lots of clothes. Scanning the tags is annoying. Also cat food, because the barcodes are so small

4. (Response #4) Demographics: female, ≈60s

Best part of the job: Talking to customers

Plausible Change: Bagging

Least favorite item: Frozen vegetables

Conducting the interviews didn’t come without fault…

Struggles with interviewing

Julia Greeley – 09/10/2021

It’s safe to say that interviewing grocery store associates, specifically cashiers, was much more difficult than expected. We entered our local Wegmans fairly optimistic that we would be capable of interviewing 10 associates, but left feeling discouraged that we were only able to collect 4 responses split between the 5 of us. Unknown to us, surveying is actually against Wegmans’ policy, so management was very adamant that we left the store, making the collection of responses much more difficult than we had originally anticipated. Despite not learning much about the struggles of cashiers, we had gained a new understanding of the difficulties of surveying and collecting research. With this newly obtained perspective, it’s very likely that we would be more gentle to surveyors in future interactions with them, because we have a better understanding of the difficulties of their job.

Our persona can be further explored in the following link:

We did not decide to design for any specific group within our target audience of cashiers. We decided that any cashier, no matter what size, gender, ethnicity, etc. should benefit equally from our decided solution. It should also be mentioned we are not designing to make the check out process easier for the customer. Their role in the check out process is not meant to change.

The cashiers had needs, so we aspired to directly meet those needs within our design process.

Defining our problem

Abby Hammel – 09/17/2021

To create a well defined problem, we went through a process of writing out our users requirements and metrics that the needs would be measured in. We learned about the importance of a well defined problem, because solutions are difficult to think of when there is no specific problem that is trying to be fixed. We have narrowed our problems down to accessibility, bagging, line length and efficiency, access to emergency services, and customer interactions. Through this, we have also developed functional requirements that our prototype must fit in order for it to benefit the maximum number of cashiers. We also now have metrics and target values that will also help us design a solution by creating a goal for us to achieve numerically.

As a group, we decided to solve the issue of scanning produce. In doing so, we could decrease line length as well as make the cashier’s job less stressful in general. If we came up with other solutions that helped the cashiers do their job more efficiently, we decided to take them into consideration for our solutions.

Discuss your solutions. How did you come up with them?

We came up with our possible solutions mainly through in-class discussion and group collaboration.

Brainstorming solutions

Julia Greeley – 09/15/2021

Included below is an unfiltered list of possible solutions, posed and debated between our group members within class time:

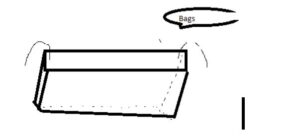

*Second conveyor belt pointed towards customers to move bags closer to customers’ carts

*Bags that open in a box-like shape in order to assist cashiers with bagging

*A chair (to emit long periods of standing)

*Bags that open upon pulling the previous bag out

*Bags that are more sturdy and/or built like a box

*A button that radios to the manager

*A button that calls 911

* A portable checkout register that is capable of moving around the store

*Product recognition device for sorting items into their food groups within the bags

In deciding on a final solution, we debated which of the solutions best targeted our goals:

| User Need | Functional requirement | Type(objective or constraint) | Metric(How will it be measured) | Specification(target value) | Priority |

| Easy bagging | Next bag opens after pulling one bag out AND the bag is sturdier | Constraint | Number of inches that the bag opens after removing the previous bag// thickness of each bag | >8in opening// >1cm thickness | 2 |

| Usable and accessible for all | No major technological requirements | Constraint | % of users able to use it | 100% of users able to use it | 1 |

| Helps line move faster | Improved line management | Objective | Only a certain number of people can line up per register | 3 people per register | 3 |

| Access to manager/ emergency services | A button that radios to management | Objective | Number of buttons present | > 1 button | 4 |

| More brief interactions with customers | Less stressful shifts | Objective | Shorter interactions between customers and cashiers due to improved design of cashier station | Byproduct of other solutions | 5 |

Unfortunately, our initially brainstormed solutions didn’t necessarily meet our standards.

Our group’s favorite solutions:

Automatic bag openers-

Product recognition software-

Accessibility and Inclusion

Connor Port – 09/24/2021

All of our solutions were adequately inclusive and did not leave out any specific groups of people, but many of them strayed from the problem that we agreed upon. Our top two choices, the product recognition system and the automatic bag openers, were not targeted towards anyone in specific, but to all cashiers.

Brainstorming a final solution

Julia Greeley – 09/20/2021

Using a brainstorming webwork methodology used in class, it didn’t take long to discover a solution that each group member approved of. Branching from some of the broad ideas that had come up in previous discussions, we were able to discover a solution that solved multiple problems that cashiers face daily. Why type in fruits and vegetables manually when grocery stores could use today’s photo-recognition technology to scan items? In scanning the items, cashiers are saved from the stress of having to memorize the codes for every fruit and vegetable, and lines at grocery stores may be shortened due to the increased productivity at each register. This idea could certainly be the beginning of a revolution in the grocery industry.

Deciding on a Prototype

Julia Greeley – 09/29/2021

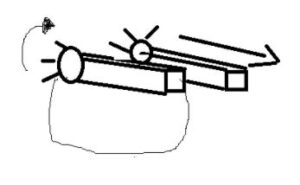

Deciding on a prototype didn’t come without a fair share of debate—gentle arguing even. Our group was split between two ideas: a scanning gun that scans produce via photo recognition, and a bar that hangs above the conveyor belt and scans all items via photo recognition.

In the case of the scanning gun, cashiers would no longer need to memorize the codes for produce, which would remove some of the stress associated with their job. But this innovation was seen as almost pointless, because integrating the technology may not be worth how small of a problem it would solve. The process for cashiers checking out items would remain mostly the same. Barcodes would still be scanned for all boxed and packaged items, so the scanning gun would only decrease the amount of time taken to recall the codes for items without barcodes (fruits, vegetables, etc.).

The bar above the conveyor belt, if the arguable complications are sorted out, could revolutionize the checkout-process in grocery stores. Cashiers would no longer need to scan items at all, rather, they could focus more of their time and energy into bagging the products, which would resolve a previously deemed stressor indicated by the cashiers we had interviewed. But, the cashier would be limited to the speed presented by the conveyor belt, as in, the items would only be scanned and bagged as fast as the conveyor belt can move, which could potentially slow the checkout process and lengthen lines at checkout. Equally, the scanner would not be able to scan items that are piled on top of each other, so items would have to be placed individually and spaced out on the conveyor.

This disagreement amongst our group called for multiple days worth of debate. Ultimately, we decided to work through the scanning bar over the conveyor, because it had more potential to make the lives of cashiers easier, which would further achieve our ultimate goal.

The solution

Julia Greeley – 10/17/2021

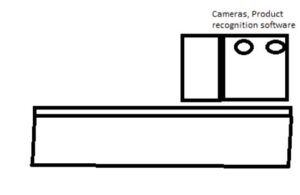

Our solution is a bar-shaped structure that hangs above the conveyor belt at the grocery store check out. The structure has two cameras, and is able to scan the items moving underneath. The integrated computer system’s algorithm is able to recognize the items via photo recognition. With this, cashiers are able to focus more on bagging rather than scanning each item individually.

How did you prototype and test your solution?

We decided to create an interactive experience for our testers in order to prototype our idea.

The Interactive Experience – Trial 1

Avery LeTourneau – 10/15/2021

Using a cardboard model of our photo-recognition scanner, a cardboard conveyor belt, ordinary items that represented groceries, and a powerpoint with images and prices of the “groceries” being scanned, our first iteration of our scanner was ready. Our testers would act as cashiers in our prototype experience and their tasks would be to:

1.Make sure all items go through the conveyor belt at one time

2. Set aside all items after they’ve been scanned (to simulate bagging)

3. If an error was to occur onscreen saying that the product was not scanned correctly, contact a manager (to simulate contacting a manager, the tester would tap one of us on the shoulder)

From our end, we would place items along the cardboard belt and pull them under our cardboard scanner. As each item moved under the scanner, we would change slides on the powerpoint to correlate with the product just scanned. We also planted errors within our test how our “cashiers” would act.

Overall, the first phase of testing went well. When watching our testers, they seemed to understand the process, not including the errors. When two different products would be in the same picture, the tester would rarely spot the issue before the error would pop up. To fix this, one tester suggested that we add specific lines on the conveyor belt to make it easier for the cashier to separate the items from each other. But, beyond the confusion, we did receive praise about our prototype. Nearly all of the testers thought it would make the cashier’s job much easier and more efficient with a bit of practice using the machine. Taking both critiques and compliments into account, the second iteration of our prototype included several changes. The first major change was the addition of a customer in the role-playing scenario. One of us would pretend to be the customer and place items on the conveyor belt. The customer would purposely make mistakes when placing items on the belt, thus creating situations where the tester would have to react to errors. The next major change would be the change from a powerpoint to a zoom call. In the previous iteration of the prototype, the powerpoint was difficult to switch from slide to slide if the cashier made a mistake. The zoom call fixed what was a clunky system in the first iteration as it allowed for the person to actively change the slides on the screen without needing to click through every single slide. The zoom call, combined with the addition of a customer, made it much simpler to understand the errors compared to the first iteration. Testers more frequently picked up on the errors compared to before. As previously mentioned, also we also added taped off boxes on the conveyor belt as our one tester had suggested.

Image: Connor creates a

‘camera’ for the first prototype

Image: User testing phase trial 1

Our users provided direct feedback to the process as a whole.

User Feedback

Connor Port – 10/04/2021

User 1 – Did not know why the last error happened. Wanted more feedback for the error. Suggested we added more complicated situations where it is obvious that there is an error.

User 2 – Says that it made the process easier. Suggested that it might be hard for the software to recognize produce.

User 3 – Notes that especially with produce, it will make the process easier. Suggested that produce is sometimes sold by weight, and that the system should account for that somehow.

User 4– Said he would love his job as a cashier if this was part of the checkout process. Suggested slots on the conveyor belt illustrated with white lines so that customers know where to place items on the conveyor belt. They could also make perfect ‘frames’ for the items to make the software’s job easier.

User 5- Thought it was very cool. Said that she usually uses self checkout, except for when she has to buy produce. Said that our demo was going a little bit too fast.

With addition of a ‘customer’, a zoom call, a scale that weighs produce, and taped-off boxes on the conveyor belt, we conducted another trial.

Trial 2

Avery LeTourneau – 10/15/2021

After testing this new iteration, it was clear that our new design was much easier to interact with than before. The tester was extremely impressed with how easy it was to operate, and said it reminded her of airport security.

The testing of out prototype revealed some weaknesses in the design.

Weaknesses within the design

Julia Greeley – 10/17/2021

If this product were to be released to the public, issues would be likely to arise in asking the grocery store customers to separate their items one-by-one on the conveyor belt. The photo recognition technology is not accurate enough to scan a pile of items and see hidden items’ specific branding without fault. Fault, in this context, results in the grocery stores losing money due to missed items being handed out for free. Customers aren’t typically excited about changes that require learning a new process, especially when that process requires that they slow down. People are busy. Asking that items be placed on the conveyor belt one at a time is a weakness in the design that would need solving though further prototyping and testing.

Images: Nathan and Avery predict the potential

issues that would arise when implementing our design

Despite the weaknesses, we can conclude that our design was successful

Success within testing our prototype

Julia Greeley – 10/17/2021

We can conclude that our design was successful because of the positive feedback we received from our users.

The cashiers we had originally interviewed stated that the process of manually inputting items such as produce was stressful and made their job more difficult. In turn, our goal was to relieve this stress by omitting the need to manually input items. Not only did we relieve the pressure of manually inputting items, we relieved the pressure of scanning items as a whole. With our design, the cashiers could now focus more on bagging the items, which heavily simplifies their tasks altogether. The individuals who tested our product stated that our design made the checkout process easier, and one student even stated that he would love his job as a cashier had this process been implemented. So, despite the weaknesses within our design and the need for many future prototypes and tests, we can state with relative confidence that we achieved our original goal to the farthest extent we were able to test. The only way to see if our design would truly be successful would be to create a fully functioning prototype, something that we do not have the resources to complete. Yet with the resources we had, we could conclude that our design was successful to a certain extent.

Image: Success!

What did your design process look like? What did you do well? What could you improve?

Avery LeTourneau – 10/14/2021

We identifed the target audience, decided on a problem to focus on solving, ideated solutions, prototyped, tested our idea, and received feedback. (SEE : The Problem –> The Solution –> Prototyping and Testing)

Here is a general overview of the things our group did well, or could improve on:

Things our group did well

- Teamwork: We worked together to discuss ideas and work through issues.

- Communication: We communicated thoroughly through text and in-person. There were no barriers preventing any of us from sharing our ideas in a group setting.

- Creativity: The solutions we brainstormed as a group were original and creative.

- Ability to adapt: Despite facing crippling setbacks in our ‘interviewing’ phase, we kept trying and eventually got a few of the supervisors that were telling us to leave to answer our questions.

Things we could improve on

- Time spent debating: Though team discourse is helpful to create meaningful ideas, our process in debating could have arguably been more efficient and less time consuming.

- Coordination: Although we ultimately completed all of our required tasks, we each ventured outside of the duties we initially were assigned. This is arguably a good thing, as it speaks to our adaptability as a group, but looking to the future, it may help us stay organized if each person remains in charge of a certain set of tasks.

Things we would change in the design process

- Adaptability: At times in the design process, it seemed like we were locked onto a certain path after deciding on something. An example of this is our problem, at times it seemed like we should’ve changed our problem, but we were unable to change it due to the constraints of the design process

- Data Collection: For our group, data collection was a struggle. If we were to go back, we would have certainly attempted to collect our users’ data in a setting away from their work.