Propulsion Team Overview

End of Year Update

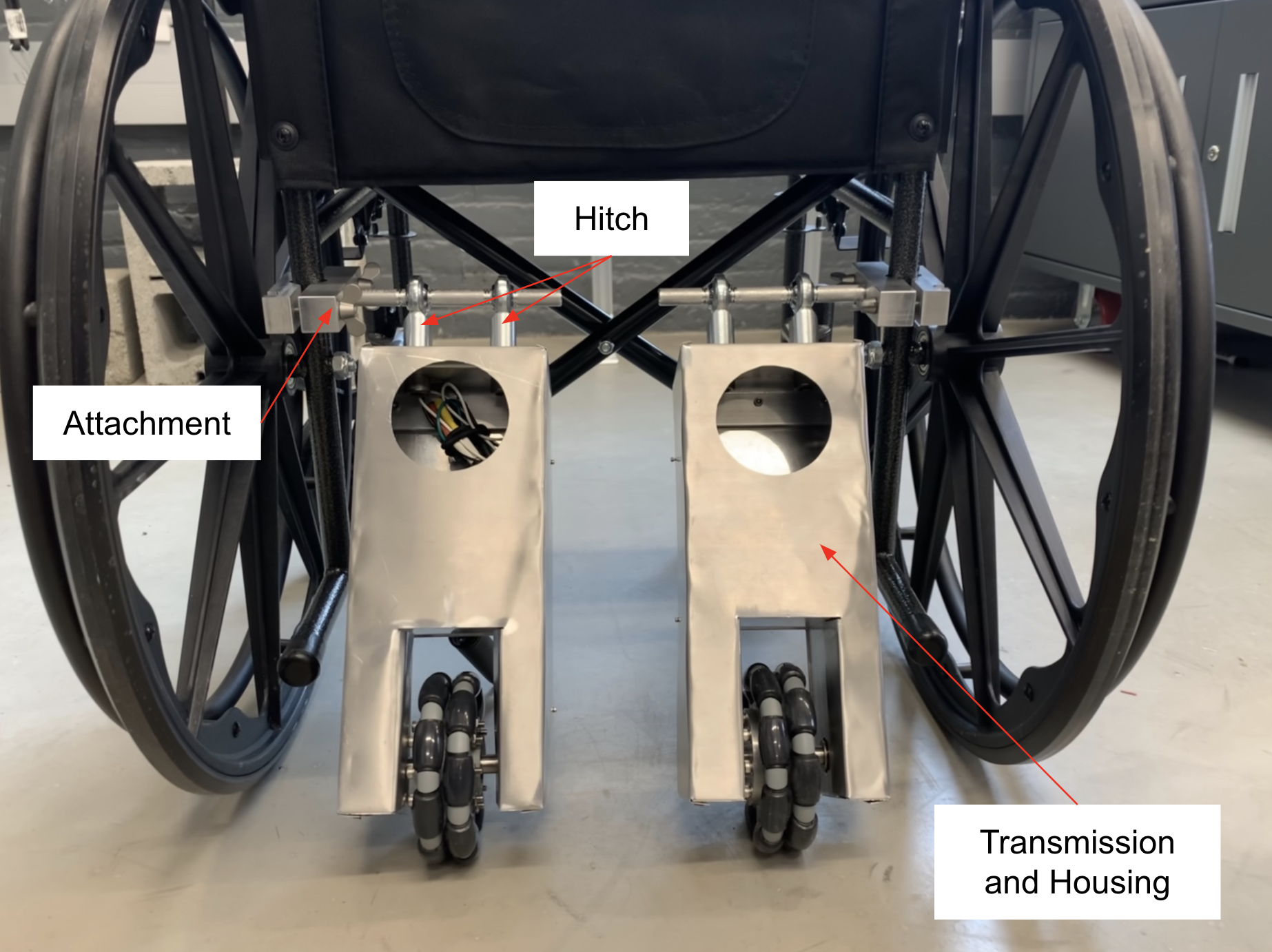

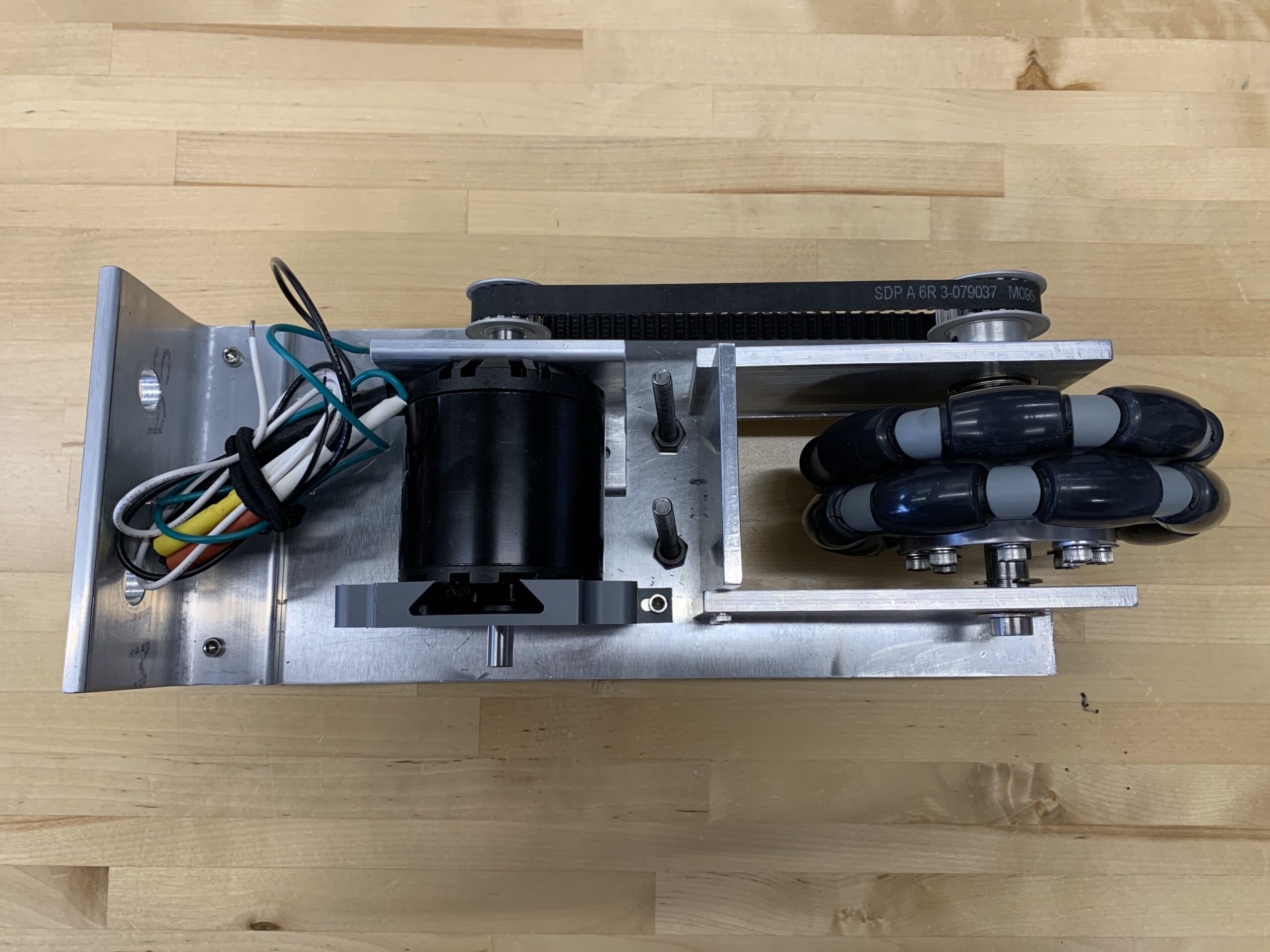

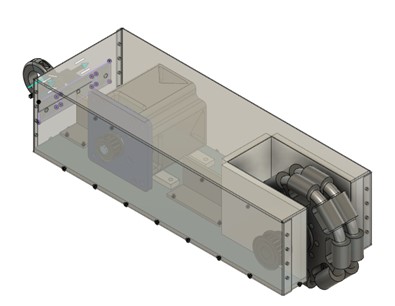

Figure 5 Propulsion Team Current Prototype

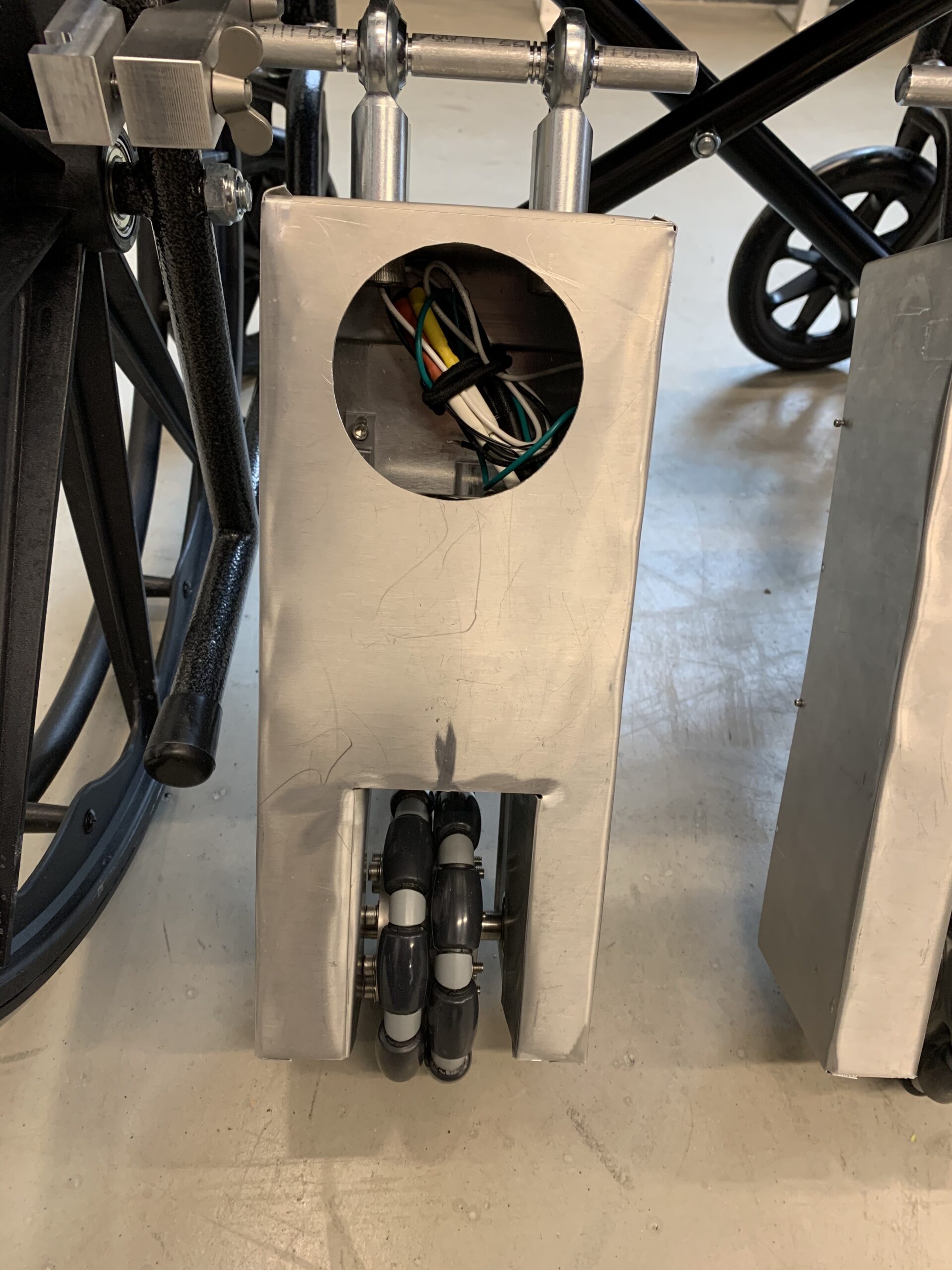

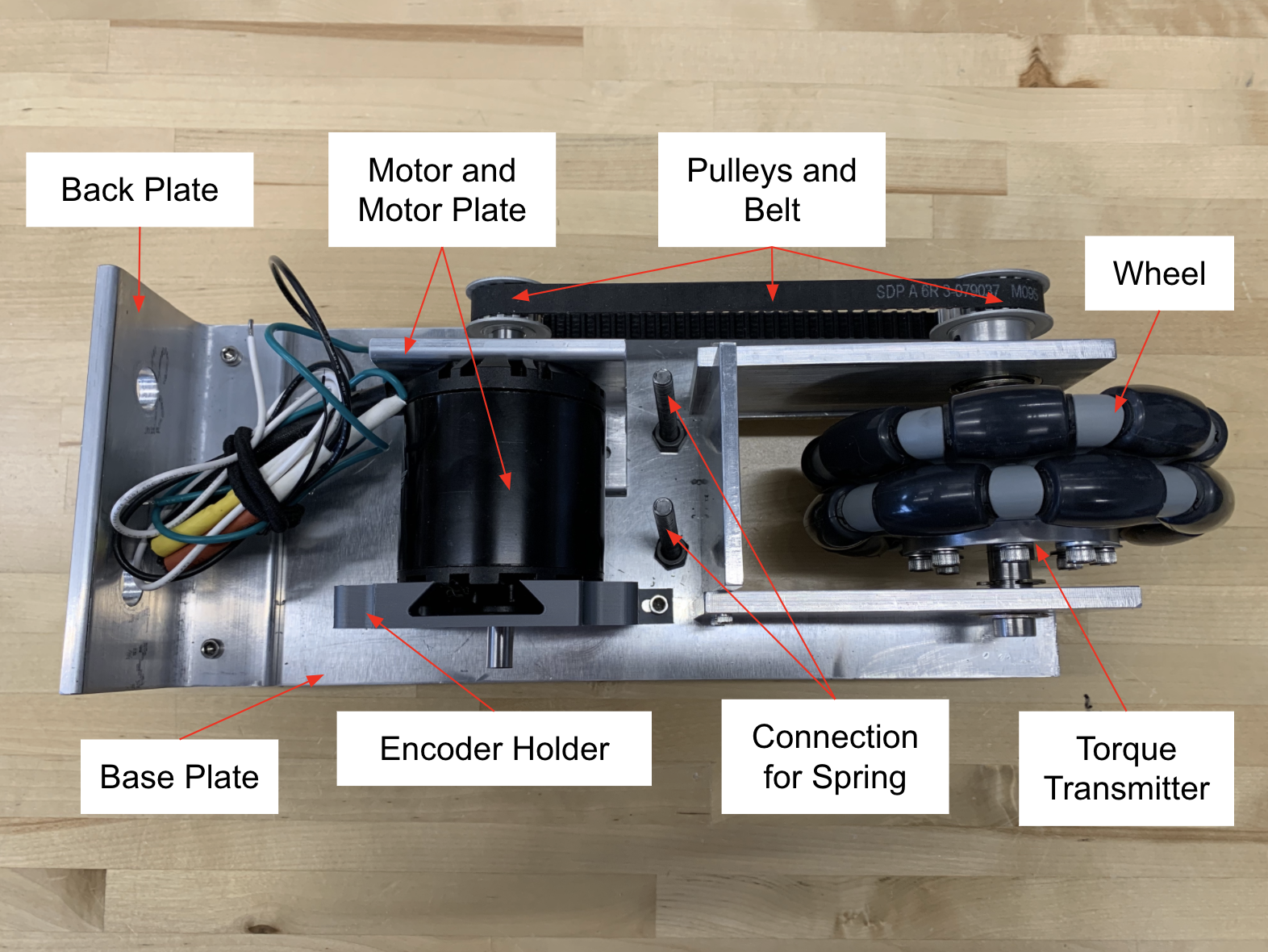

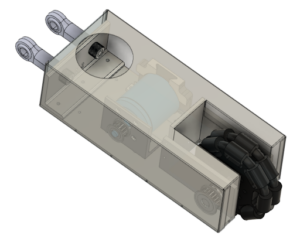

Figure 5 Propulsion Team Current Prototype Figure 6 Transmission and Housing

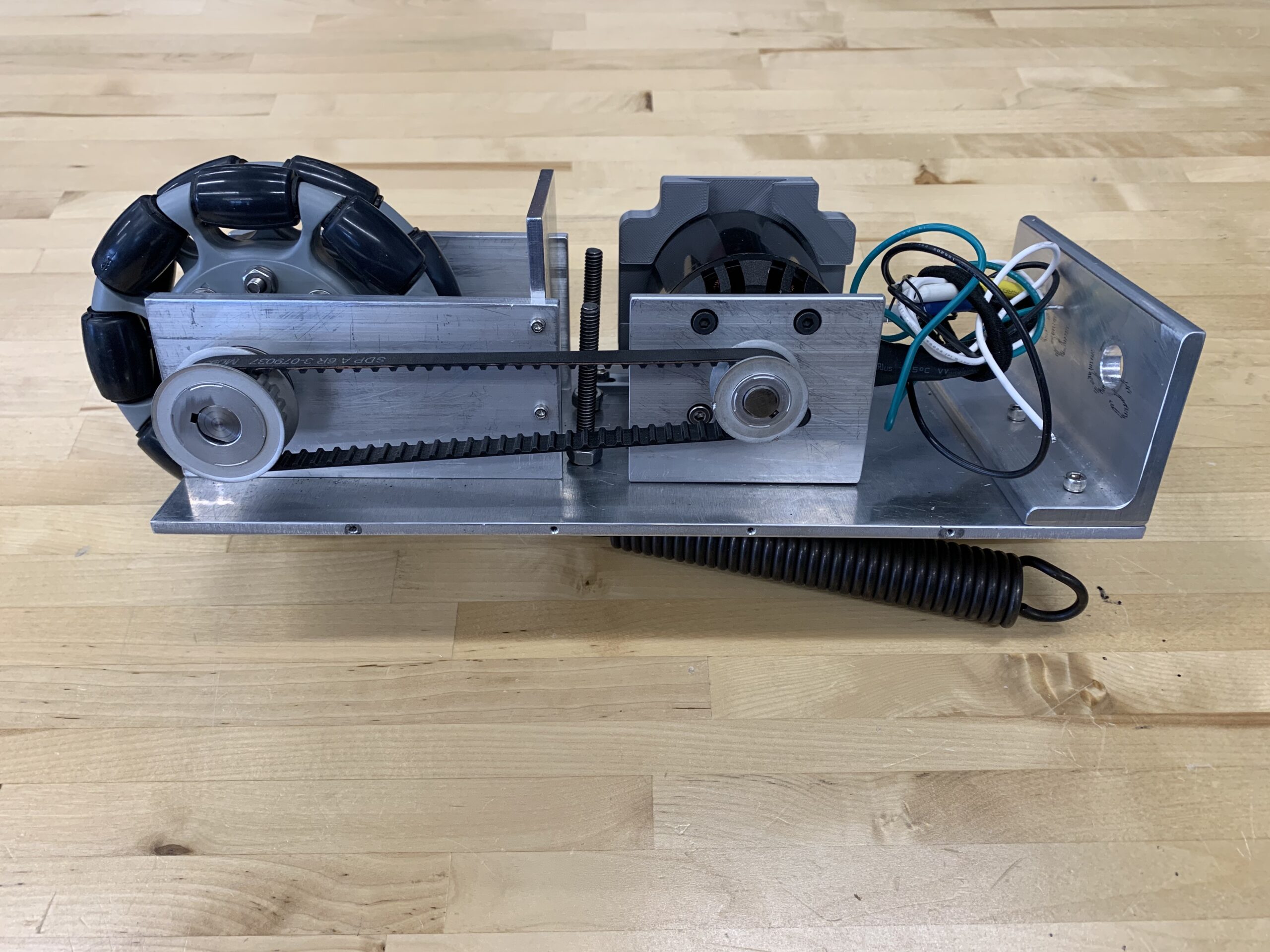

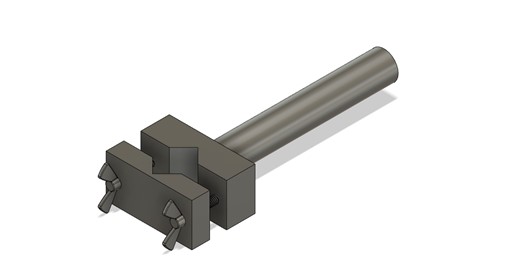

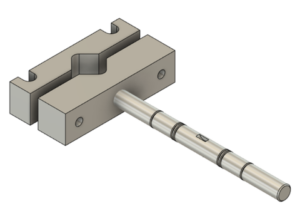

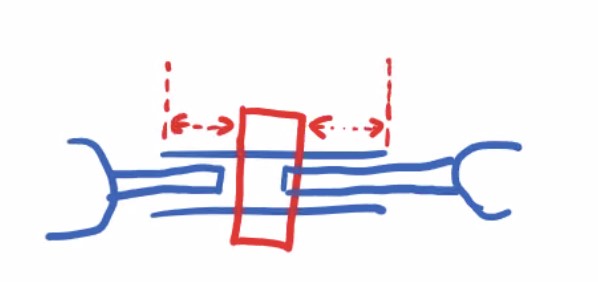

Figure 6 Transmission and Housing Figure 7 Drive Shaft

Figure 7 Drive Shaft Figure 8 Rotacaster Wheels and Torque Transmitter

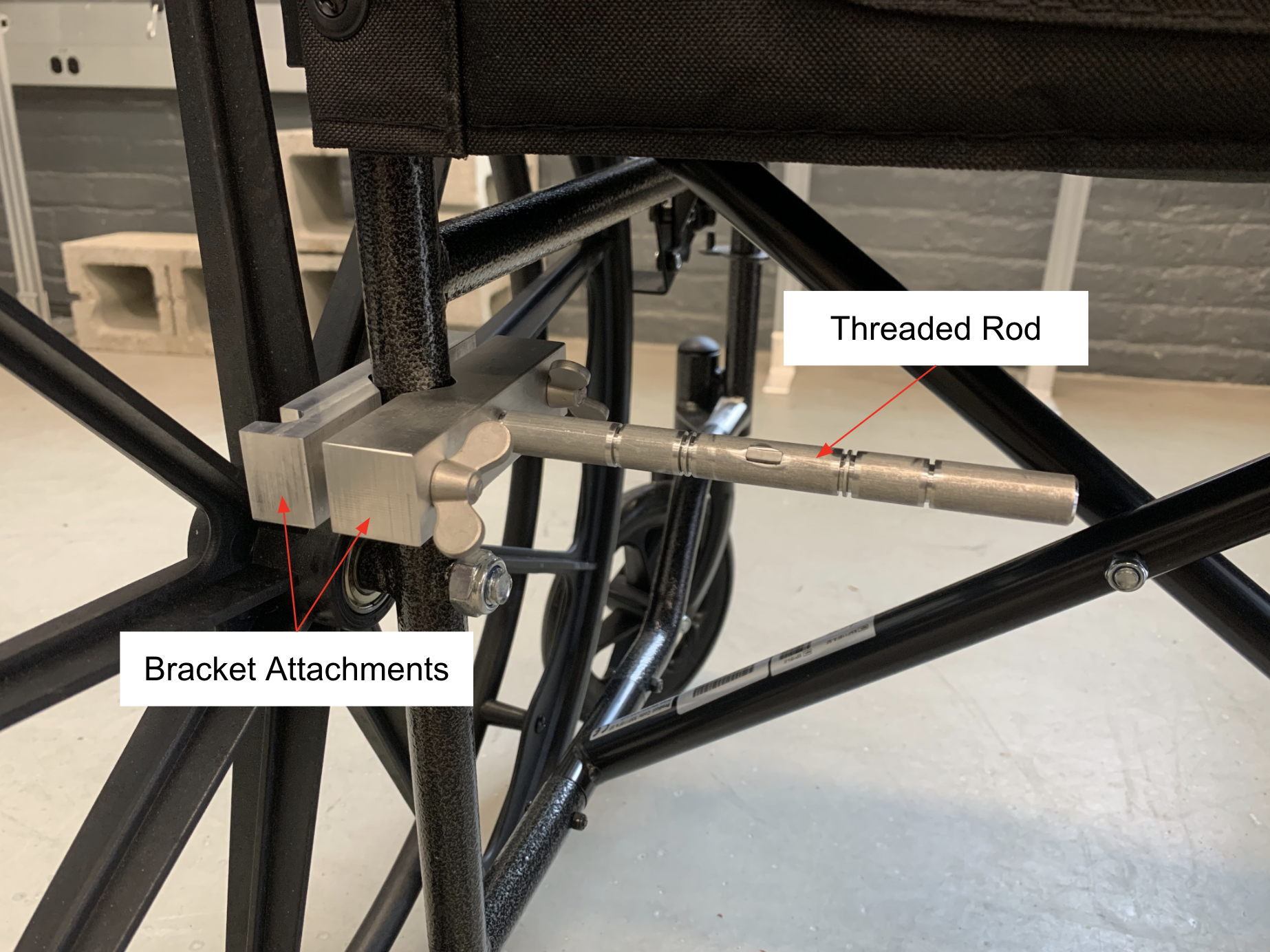

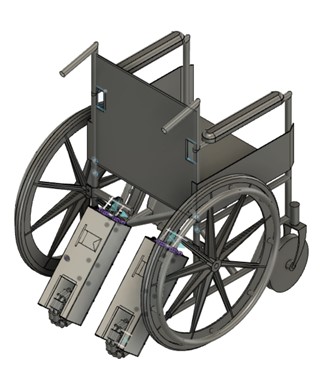

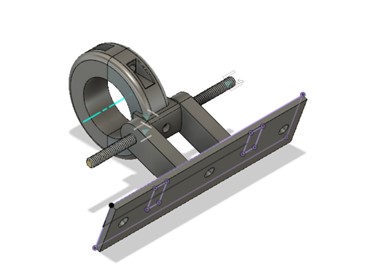

Figure 8 Rotacaster Wheels and Torque Transmitter  Figure 9 Attachment mechanism that clamps to the frame of the wheelchair

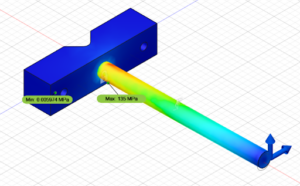

Figure 9 Attachment mechanism that clamps to the frame of the wheelchair  Figure 10 Stress Analysis on the attachment rod

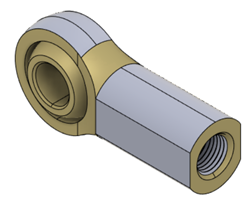

Figure 10 Stress Analysis on the attachment rod Figure 11 Connection between the transmission and housing and the attachment rod

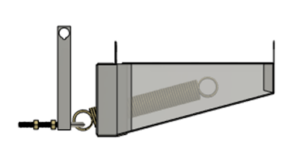

Figure 11 Connection between the transmission and housing and the attachment rod Figure 12 Spring Attachment Bar

Figure 12 Spring Attachment Bar  Figure 13 Spring Assembly including the spring, attachment bar and two part aluminum housing

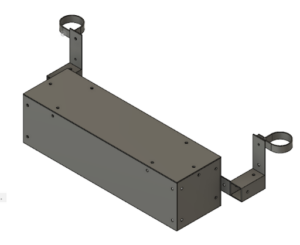

Figure 13 Spring Assembly including the spring, attachment bar and two part aluminum housing Figure 14 Battery housing

Figure 14 Battery housing

Progress Update: Mid-March

Motor Test Run

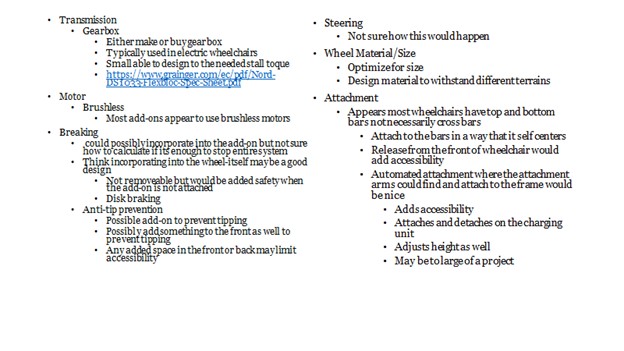

End of the First Semester Designs

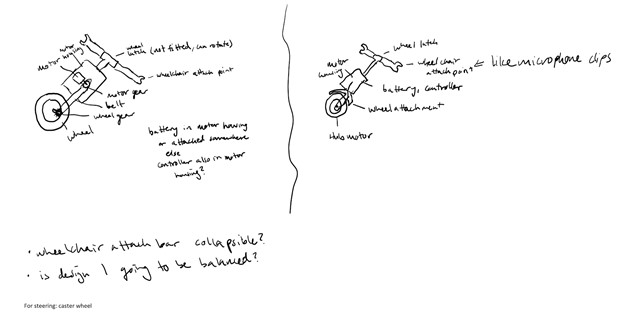

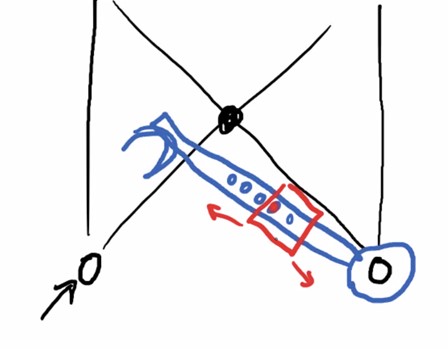

Conceptual Designs

Figure 1 Propulsion system with belt driven wheel

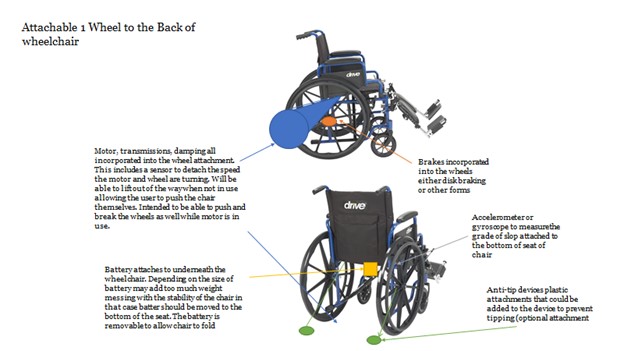

Figure 1 Propulsion system with belt driven wheel Figure 2(a) Propulsion system with singular wheel

Figure 2(a) Propulsion system with singular wheel Figure 2(b) Propulsion system with one wheel possible configurations

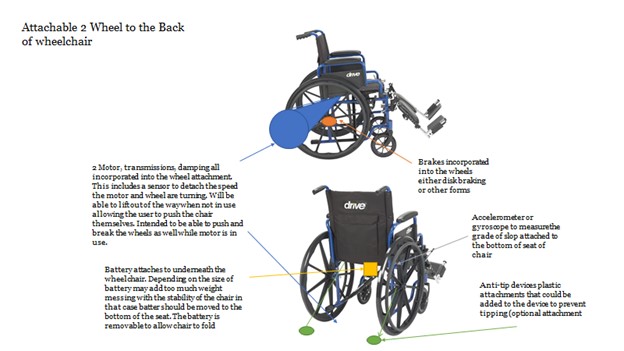

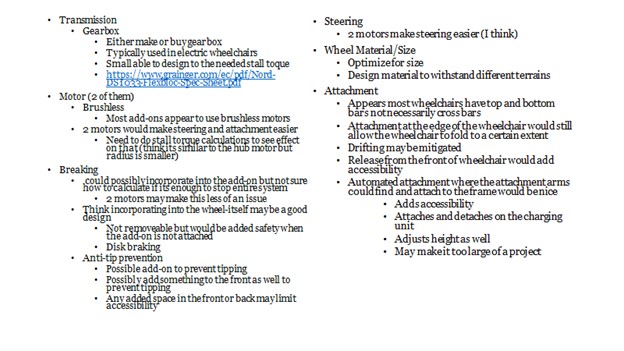

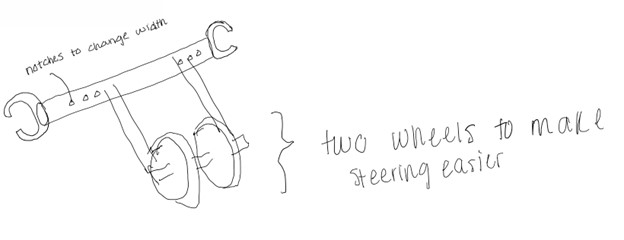

Figure 2(b) Propulsion system with one wheel possible configurations Figure 3(a) Propulsion system with two wheel

Figure 3(a) Propulsion system with two wheel Figure 3(b) Propulsion system with two wheel possible configurations

Figure 3(b) Propulsion system with two wheel possible configurations Figure 4 Propulsion system with two wheels

Figure 4 Propulsion system with two wheels Figure 5 Propulsion system with one wheel

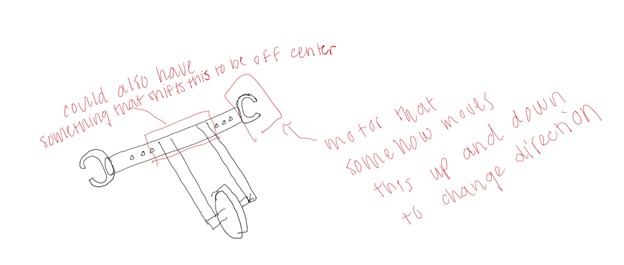

Figure 5 Propulsion system with one wheel Figure 6 Propulsion system attachments configuration

Figure 6 Propulsion system attachments configuration Figure 7 Propulsion system attachments configuration

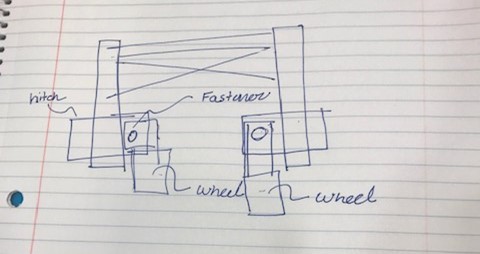

Figure 7 Propulsion system attachments configuration Figure 8 Propulsion system attachment and wheel configuration

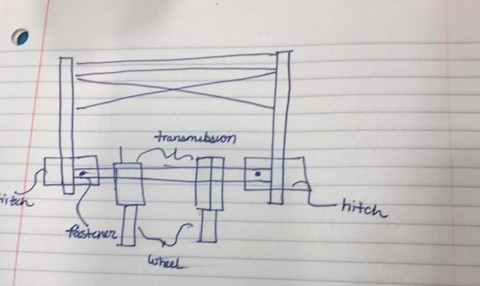

Figure 8 Propulsion system attachment and wheel configuration Figure 9 Propulsion system attachment, transmission, and wheel configuration

Figure 9 Propulsion system attachment, transmission, and wheel configuration

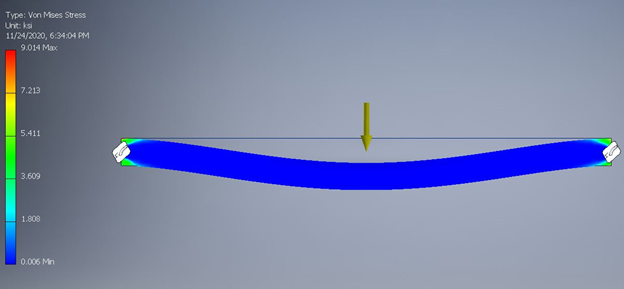

Calculations and FEA Analysis

Figure B.14 ANSYS stress analysis for attachment full span shows maximum stress as 9.014 ksi

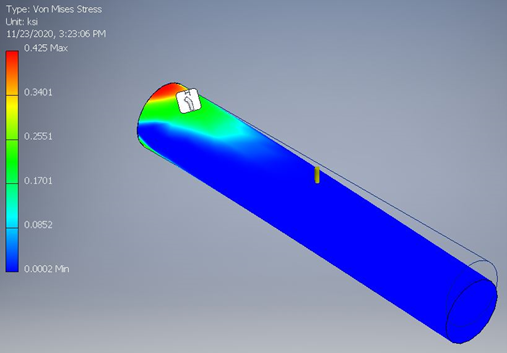

Figure B.14 ANSYS stress analysis for attachment full span shows maximum stress as 9.014 ksi Figure B.15 ANSYS stress analysis for attachment partial span shows maximum stress as 0.425 ksi

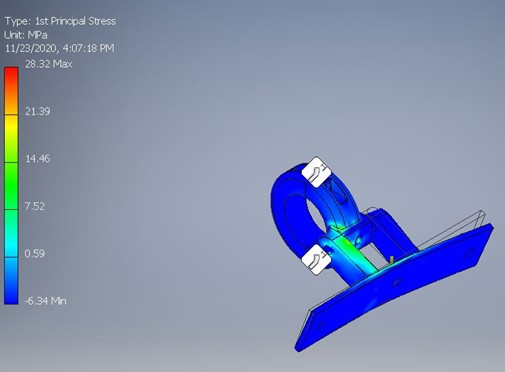

Figure B.15 ANSYS stress analysis for attachment partial span shows maximum stress as 0.425 ksi Figure B.16 ANSYS stress analysis for the hitch attachment shows maximum stress of 4.11 ksi

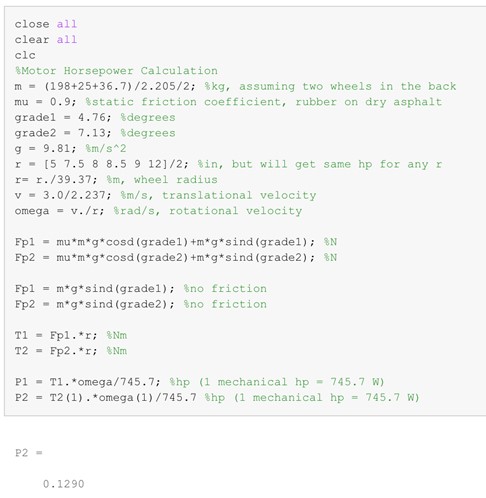

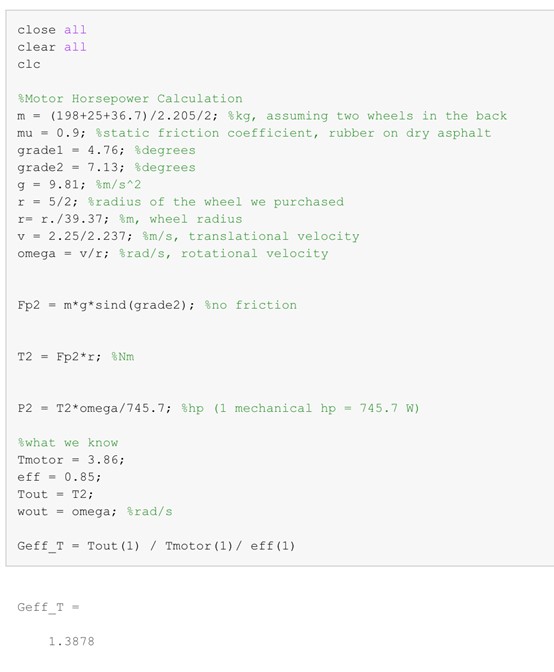

Figure B.16 ANSYS stress analysis for the hitch attachment shows maximum stress of 4.11 ksi Figure B.17 Motor horsepower calculations in MATLAB

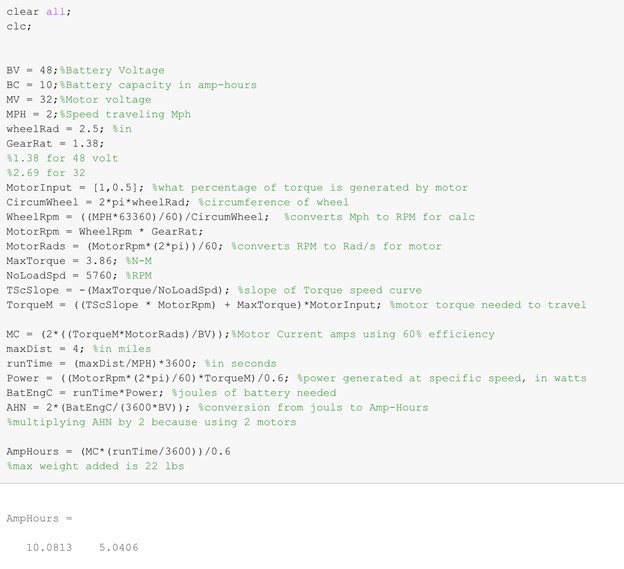

Figure B.17 Motor horsepower calculations in MATLAB Figure B.18 Battery ampere hour calculations for chosen motor in MATLAB for running motor at 100% and 50%

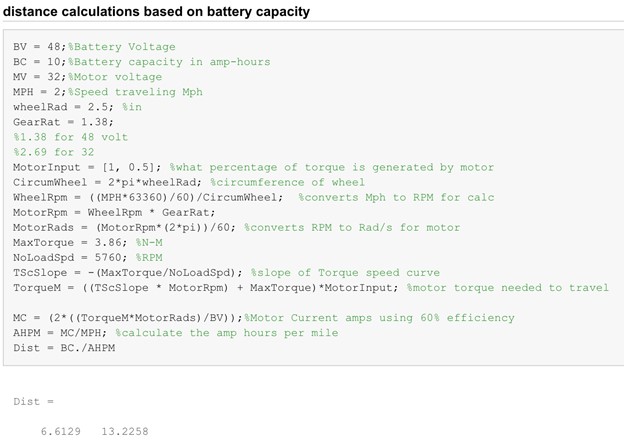

Figure B.18 Battery ampere hour calculations for chosen motor in MATLAB for running motor at 100% and 50% Figure B.19 Distance calculations based on battery capacity for chosen motor in MATLAB for running motor at 100% and 50%

Figure B.19 Distance calculations based on battery capacity for chosen motor in MATLAB for running motor at 100% and 50% Figure B.20 Gear ratio calculations in MATLAB

Figure B.20 Gear ratio calculations in MATLAB