Our team knew that the Beta Prototype would need to integrate the work of the three subteams (structure, tracking, and electrical) to result in a final product that satisfied our functional requirements. With this in mind, we began brainstorming ideas, sharing our visions, and understanding the changes each system would have to undergo in order for the prototype to be successful. One of the greatest examples of these changes was our team’s pivot from a bogie-style drive system to a more traditional tank-drive system following discussions about motor control.

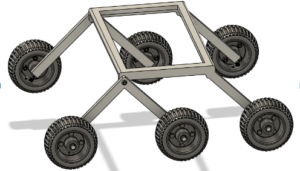

Original bogie design

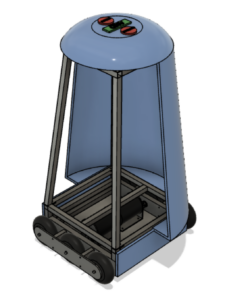

Updated chassis with tank drive

The bogie design is shown here. Each wheel was intended to be driven by an in-hub motor. However, these wheels would’ve had separate motor controllers, complicating the operational system.

Our updated chassis model uses only 2 motors, both connected to the same motor controller. Each motor drives a center wheel on one of the robot’s sides and the axles are connected by chains and sprockets. Our team made decisions about the robot’s size and center of mass, motor torque, exterior shell, and control system to ensure the initially separate systems we developed during the Alpha prototype would work well together, culminating in a robust functional prototype.