Tests were conducted on the basis of evaluating drill guide performance and operation when used as a tool to execute an ALLR procedure in conjunction with ACLR. Out of all our functional requirements, the testing protocol aimed to assess three important functional requirements: tunnel convergence, adjustability, and minimizing the number of portals. Tunnel convergence is the main objective of the guide and testing will confirm that the drill guide design can be oriented in such a way that drill an ALLR procedural tunnel while ensuring a conflict with the ACLR tunnel does not occur. Adjustability is also crucial since patients vary in size and therefore different knee sizes should be accommodated for. Number of portals was heavily weighted for Oasis since the minimum of one portal was a primary design goal.

Outline of the testing protocol can be found here.

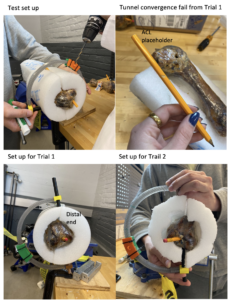

The first practice test determined that the Oasis prototype exhibited difficulties for finding the correct angle when positioning the guide. This is a reasonable observation since Oasis did not have angle indicators for establishing the correct position. Overall, key findings included:

- Difficulties achieving correct angle placement

- The drill bit deemed too small for proper drilling (not an issue with the guide but with the testing rig)

- Poor Stabilization for drilling

- Adjustability for knee size was inconsistent

Two trials of testing were conducted. On both attempts, Oasis failed. Failure of tunnel conflict resulted from not being able to prevent tunnel convergence or creating a tunnel far from an ideal expectation. Oasis only required one portal for the drill. In addition, adjustability was not fully considered here since there were only 3 trials, however we believe it will be successful for this test provided there will be a long enough drill bit.

Despite multiple failures, we do not think this is grounds for discontinuing progress on Oasis since the prototype had no failsafe mechanism.

One aspect that we plan on improving is the drill portal width. Because this was very small, the drill came in at a different angle than desired and specified by the guide.

Additionally, after we adjusted the prototype to line up with the outside of the femur, the drill would sometimes not be long enough to reach the bone. One way to improve this in the future is to make the C-shape a bit smaller. Moreover, we will be more familiar with operating the device before testing it.

Furthermore, we will need to design a mechanism for the two sliding end pieces that are connected to the C-shape body.

Lastly, we will make the screw more stable to ensure that there will not be any slipping during the testing procedure.

The chart above indicates that the Oasis prototype was only sometimes successful. This is attributed to the lack of a specified drill angle and failsafe mechanism, impacting reliability.

*Fail – pencil had drill marks indicating a tunnel convergence.

*Adjustability was not able to fully be tested in this prototype due to the small amount of trials.