L-Shape Iterations

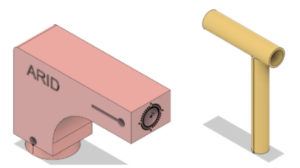

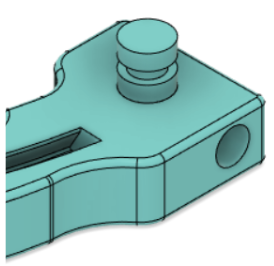

The selected L-shaped attachment went through a number of iterations to look like it does in the final prototype. It began simply as a shape with two different mounting holes at arbitrary dimensions just to gauge the feasibility of this kind of attachment. There was the issue of mounting the attachment onto the handle, the first solution idea being using magnets. This in theory was an interesting idea to maintain flexibility and ease of use, however practically it was difficult to mount the magnets in place and trust that they could prevent applied moments from the side. Instead, extensions were added to the handle on either side with slots so that the attachment could be mounted using set screws while still being able to be rotated.

The drill-end of the attachment has a simple hole that the drill slot can slide into, and also utilizes a slot for a set screw which still allows rotation to adjust drilling location in a different plane. Both of these set screws can be loosened to adjust both the angle of the attachment as whole, and the angle of the drill slot itself, which are in two different planes relative to the ACLR drill.

After initial testing, the shape of the attachment was adjusted in order to allow further adjustment of the drill slot by extending the mounting hole to function more as a slot that could be extended and retracted, adding another level of location adjustment. Lastly, the handle-mounted end of the attachment was edited to be circular at the base This allowed angle ticks to be drawn/printed on said cylindrical base with a marker on the handle that provides a numerical reference for the position of the attachment. A similar method can be used on the ALL drill slot at the opposite end of the attachment to provide an exact reference for the angle of that trajectory as well.