We discussed all of our ideas from concept generation as a group, and combined similar themes and functionalities until we were left with two designs: a standalone ALLR drill guide and a 2-in-1 ALLR and ACLR drill guide. We broke off into two design teams to discuss and refine these concepts further, leading to the OASIS and DUNE sub-team structure we employed for the alpha prototype.

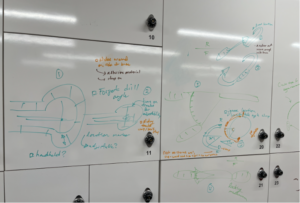

The image below depicts the brainstorming session from which the Oasis design originated. Amongst other designs, the concept of a wraparound C-shaped guide is indicated by designs 3 (emphasizing angle specification) and 7 (emphasizing ergonomics).

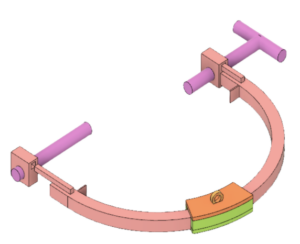

The idea behind our Oasis design was that it would limit the amount of portals used, while accurately reaching the desired drilling angle. Once our idea was refined, the Oasis sub-team created a very low fidelity prototype out of cardboard. This prototype was meant to be extremely basic and give a rough idea as to what the 3D printed product would look like.

After creating this prototype, the team was able to see design flaws and adapted the prototype when designing in Fusion. For example, one flaw was the fact that the guide would always be drilling to the center of the knee. After having a team discussion about this problem, we decided to draw our design on the board and looked at possible solutions. The best solution that the team came up with for this problem was to create a sliding mount positioned where the clamps are located so that the guide can account for different sized knees and always drill 30° from the outside of the femur. Another issue we faced was the C-shape curve. We realized that if we wanted the slider to be able to move along the shaft, it would need to be a perfect circle. Moreover, the drill hole size was adjusted as the testing team provided us more information on their testing protocols. Furthermore, we printed the screws as cylinders. We did this because it was easier to create from the 3D printer. We did not design this prototype with specific mechanisms to help get to a desired distance using the support structure connected to the two ends of the C-shape body. In future iterations, we will design a better mechanism for it.

After creating this prototype, the team was able to see design flaws and adapted the prototype when designing in Fusion. For example, one flaw was the fact that the guide would always be drilling to the center of the knee. After having a team discussion about this problem, we decided to draw our design on the board and looked at possible solutions. The best solution that the team came up with for this problem was to create a sliding mount positioned where the clamps are located so that the guide can account for different sized knees and always drill 30° from the outside of the femur. Another issue we faced was the C-shape curve. We realized that if we wanted the slider to be able to move along the shaft, it would need to be a perfect circle. Moreover, the drill hole size was adjusted as the testing team provided us more information on their testing protocols. Furthermore, we printed the screws as cylinders. We did this because it was easier to create from the 3D printer. We did not design this prototype with specific mechanisms to help get to a desired distance using the support structure connected to the two ends of the C-shape body. In future iterations, we will design a better mechanism for it.