ALPHA PROTOTYPE PROPOSAL

Team ARID

Description of Prototype

The first ARID prototype will test mainly for feasibility and strategy for achieving the main functional requirements. This involves primarily making sure there is a working function in the tool that prevents the Lemaire LET drill tunnel/attachment point from intersecting or interfering with the ACL reconstruction femoral drill tunnel. This may involve a dual-purpose drill guide that is used for both tunnels, or a standalone LET tunnel guide which references the existing ACL femoral tunnel. Also, to be considered in this prototype will be the ability to manufacture beyond the rapid prototyping phase (i.e. with more durable biocompatible materials such as metals).

The audience for the prototype can be medical practitioners, medical students, hospitals, and patients. Medical practitioners, medical students, and hospitals can give useful advice on feasibility and assessing expected functionality. Medical practitioners, like Dr. Grant, are familiar with the latest developments in the health space, which is useful in knowing if our deliverable/purpose is within the public’s interest.

Although patients are not experienced with the topic of ACL repairs so their input will not be of help for the alpha prototype, which means we will not reach out to them in the alpha prototype stage, it is important to keep patients in mind during the developing phase.

Intention / Purpose of Prototype

In the first prototype, multiple functional requirements will be evaluated, especially the most important constraints discussed in our previous poster presentation. As a team we have decided that in order for the device to be a success, it absolutely must avoid tunnel conflict, and in doing so will provide the drill with a correct location and angle, as well as entering through the least amount of portals, and be able to fit a drill. In the process of evaluating these, we may be able to evaluate some lower priority requirements as well, possibly including being able to read at an arm’s length, comfortable to hold, ect.

In the alpha prototype, we aim to evaluate the feasibility of the concept. In order to do this, CAD modeling will be utilized. These models can provide a visual for the team as well as for stakeholders in order to form discussion around whether or not the concept is feasible and how to proceed. Feasibility will be evaluated based on the functional requirements, ease of use, level of complexity, and most importantly, that the device will drill at the correct location and angle in order to alleviate risk of tunnel conflict. The model as constructed will likely look similar to existing drill guides, as the team will be using the existing guides as the basis for our concept generation.

Evaluation Procedure

The functional requirements will be important for this phase of prototype development. The functional requirements that can be tested based on the material that is being used will be evaluated. This will involve us going through the functional requirements and determining which functional requirements can be tested at this point for our prototype. For the alpha prototype, some of the functional requirements that we are aiming to assess are drill angle, drill location, minimum number of portals, etc. Through benchtop testing and conducting interviews with experts, we will collect data that will allow us to analyze if the functional requirements are satisfied. We will use a knee model to test the functional requirements that were deemed most important for this phase of prototype development. Most likely, we will have a list of the functional requirements that we are aiming to satisfy and check these off if the prototype fulfills it.

Testing protocols for each functional requirement (that will be tested in this alpha prototype) will be generated. Upon collecting quantitative data for each functional requirement, we will compare the collected data to the defined specifications for each functional requirement. As long as the collected data for each functional requirement is within the range of the specification, the prototype passes the test for that functional requirement.

Different stakeholders will be involved in different parts of the evaluation, but the goal during this phase of prototype development is to include testing or other feedback from as many stakeholders as possible.

- Medical Practitioners

-

-

- Direct feedback from talking with interviewed doctors during the design phase and the end of the Alpha prototyping will be at least valuable feedback in Ideation of the beta prototype. We also expect that medical practitioners will be included when discussing how to incorporate the more challenging or nebulous functional requirements.

-

- Residents/trainees

-

-

- Feedback and talking with resident doctors/surgical trainees about current uses of guides in teaching and their reactions to our prototype will be needed for ideation on the Alpha prototype.

- Likely not relevant for alpha phase

-

- Hospitals

-

-

- While harder to reach, this could be looked at in two ways. Cost of the guide is probably most important to this stakeholder, so the total cost of the prototype and projections of the cost in production will be a metric that this stakeholder is interested in and should be considered in the evaluation. If there is a connection to a hospital management staff their reaction to the guide could be included in the evaluation, but shouldn’t be required.

- Likely not relevant for alpha phase

-

- Patients

-

-

- Patients are included as guides and are hopefully able to improve healing time after the surgery and experience less failed surgeries. It is important to keep patients in mind during the alpha phase, but they are not experienced with the topic of ACL repairs so their input will not be of help at this time.

-

- Families

-

-

- It is important to consider the impact of our device on families of patients. This being said, families of patients are not experts on the topic of ACL repairs and therefore, it is not important for us to reach out to them during this phase of prototyping.

-

- Insurance companies

-

- Cost and reliability is most important to insurance companies, evaluations of cost and longevity of the guide should be how this shareholder is taken into consideration.

- Not the most important at this stage but will be kept in mind

Fabrication

With regards to fabrication, we will build a device made of simple objects (cardboard, paper, rubber bands, paper clips, etc.) that is meant to evaluate feasibility for a certain functional requirement(s). For higher fidelity prototypes, such as one that would serve as our alpha prototype, this would likely mean 3D printing our design (from a CAD model build file) out of a polymer filament material with the printers available to us at Lafayette.

Testing

To create testing protocols for the prototype, we will research testing protocols of similar products to inform those for our prototype. Tests would be needed to evaluate our prototype’s ability to fulfill each functional requirement we are testing for. Potential tests include using a Styrofoam or wooden cylinder model to represent the knee for tunnel conflict testing.

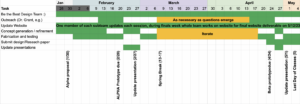

Timeline

Throughout the process, we expect that we should be in contact with the interviewed doctors if and when we reach a difficulty in the ideation. Direct feedback from talking with interviewed doctors during the design phase and at the end of the Alpha prototyping will be valuable feedback in Ideation of the Beta prototype.

Resources/Budget

Prototype 1 – very low fidelity (PVC, cardboard, paper, rubber bands, paper clips), amounting to a rough estimate of $20. Not many material property functional requirements can be tested with such lower fidelity models. This ideation would likely be used in order to confirm feasibility of alleviating tunnel conflict.

Prototype 2 (alpha) – material to be able to incorporate physical functional requirements, so likely a plastic material fabricated by a 3D printer. This would also be low cost within the same range.

Fabrication

- 3D printing in house (not very costly)

- If chose to machine from metal: likely stainless steel or aluminum

Testing

- Knee model

- Knee cadaver / pig knee / dog knee / etc. (costly, $X00 – $X000 [source])

Team Member Roles and Contributions

Alex Barlow:

I would like to be involved in concept generation and our strategy for doing so as a team. I think I am able to lead some of these discussions to achieve a design/concept that the team agrees is feasible and accomplishes our goals. I am also very interested in the fabrication of this device, so will work with Scott and be involved in the fabrication of parts. Along with this I will look at design quality, and make sure the parts of our device can serve their purpose effectively and efficiently, while being feasible to manufacture (Fabrication Manager). I would like to develop some management skills with this role, as well as familiarize with manufacturing strategies and techniques.

Yizhu Chen:

I would like to take part in the concept generation aspect of the project. I would be interested in participating in the manufacturing process (including CAD modeling, creating dimensioned engineering drawings, 3D printing, Laser cutting, working with the shop, and assembling) since I have done something like this before and I enjoy doing the manufacturing process. I also would like to participate in the designing process, but I don’t have too much knowledge and experience with surgery tools, so I might not be very helpful, I will try my best. I hope I can learn how to work more efficiently and comfortably in a team. I also want to be more familiar with the design and manufacturing process of a product.

Nate Bontje:

I will be a part of concept generation to start and my main focus will be in testing. I don’t have much experience with CAD or manufacturing, but I have experience in assay creation and data science, both of which will be valuable to the team. I would like to work with the manufacturing team to learn more about the concepts I don’t know, but don’t think it should be my main focus as I doubt I’ll be very helpful moving it forward.

Grace Steurer:

I will take part in concept generation as well as being a scribe. I would like to spend the majority of my time in the testing subgroup if possible but I do have quite a bit of knowledge in autocad and other modeling software, so I would be happy modeling the guide as well. I hope to learn about the process of prototype creation and testing, as well as improve my knowledge on the biological aspect of this project: the anatomy of the knee.

Lauren Schuster:

I will take part in concept generation as well as being a scribe and updating the website for whichever team I am part of. I will be happy to be part of either the testing or building team (I would prefer not to work on cad though). I hope to learn more about the anatomy of the knee as well as what goes into both testing and creating the prototype.

James Galbraith:

I will take part in concept generation as well as being a scribe (if needed). I would like to be part of a testing group since I am interested in surgery and the fusion of anatomy/physiology and the material properties of our device and the engineering principles and processes that went into conceptualizing and realizing our product. I would also be interested in participating in the manufacturing process (including CAD modeling and 3D printing) since these could be valuable skills to have in the medical device industry, one I am interested in going into.

Bobby Oehrlein:

I would like to take part in the concept generation aspect of the project. I believe that the more people we have working on this part of the project so that everyone can bring in their ideas, at least for the first prototype. I believe I would like to spend more time working on the testing aspect of the tool once we have a prototype. However, I am willing to work wherever since I want to gain as much of an understanding of this entire process as possible.

Zach Fiske:

I would like to take part in concept generation, devising testing protocols, outreach, and modeling / manufacturing as necessary. Being a part of the testing team and interfacing with different subgroups and with stakeholders is what excites me the most. From developing the alpha prototype I hope to better learn how to turn numerous brainstorming ideas into a handful of testable prototypes as a team.

Darby Aurelien:

I will contribute any ideas I may have during concept generation. I would be happy to help with the modeling of any initial designs. I hope to improve skills in modeling, dimensioning drawings, and overall turning concepts into a physical prototype throughout developing the alpha prototype.

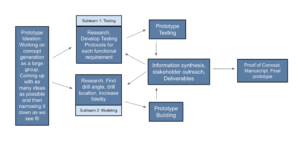

Subteam Ideation

During the alpha prototype phase, we will be initially working in a large group for concept generation. This will allow us to come up with as many ideas as possible. We will then split into two subteams: testing and modeling, in order to divide the workload and best use our skills.