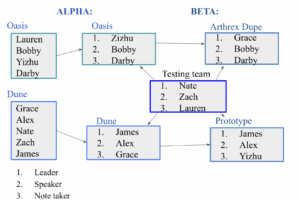

Each member of the sub team is responsible for contributing to the task their group has been assigned. Additionally, each member of the three sub teams have been assigned a role. Those roles are leader, speaker, and notetaker. The leader is responsible for overseeing general progress of their team, the notetaker is responsible for keeping detailed notes of the teams progress, and the speaker is responsible for reporting back to the entire group and updating the rest of the team on their progress. The testing team remained the same since the formation. While there have been multiple teams throughout the semester, we all collaborate and help other teams when needed.

Alex Barlow: ALL Arm Extension design Co-Leader, worked to create the addition to the Arthrex RetroConstruction™ model which would allow adjustable and accurate drilling trajectory while maintaining a solid construction and assembly. Led assembly of device and design iteration for improving the functionality, presented findings through stages of design, manufacturing, and testing. Greatly improved concept generation and ideation skills for problem solving, as well as presentation/speaking skills.

Yizhu Chen: ALL arm extension design Co-Leader, worked to create the addition to the Arthrex RetroConstruction™ model which would allow adjustable and accurate drilling trajectory while maintaining a solid construction and assembly. Focused on creating the CAD model of the add-on part, generating STL and G-Code files for 3D printing, 3D printing most of the components, machining the components, and assembling the components. Greatly improved concept generation and ideation skills for problem-solving, as well as time management and how to work more efficiently and effectively as a team.

James Galbraith: ALL Arm Extension design Co-Leader, worked to create the addition to the Arthrex RetroConstruction™ model which would allow adjustable and accurate drilling trajectory while maintaining a solid construction and assembly. Liaised with our primary stakeholder, orthopedic surgeon Dr. John Grant, to set up and facilitate meetings to discuss design ideas and progress. Researched proper surgical procedural techniques and helped inform the testing protocol to reflect these. Greatly improved concept generation and ideation skills for problem solving, as well as speaking skills in the form of presentation of findings and stakeholder interaction.

Grace Steurer: Arthrex Duplicate design Co-Leader, worked to produce a working model of the Arthrex Flip-Cutter III® RetroConstruction™ drill guide, which would allow for accurate and consistent drilling of the ACLR tunnel. I largely focused on creating the Fusion 360 model and drawings to communicate with the manufacturing contact. I documented the discussions and decisions during our meetings in order to organize and reference information as needed. I created a flowchart depicting the project plan and kept it updated as we progressed through the semester. Over the course of this project I greatly improved my Fusion skills and overall knowledge of the manufacturing process. I deepened my comfortability with the brainstorming process and concept ideation process. Most importantly, I gained confidence and comfortability working on a team-based engineering project.

Darby Aurelien: As an Arthrex Duplicate design Co-Leader, I played an instrumental role in the development of a model version of the RetroConstruction™ drill guide, aimed at improving the combined ACLR and ALLR surgical procedure. I used Fusion 360 to design components and created appropriately dimensioned engineering drawings for manufacturing. My learning outcome of time management proved to be invaluable as I helped ensure timely delivery of assemblies to inform prototype and testing sub-teams.

Nathan Bontje: As Testing Co-Leader, I worked with teammates to design and carry out a testing protocol in order to test the effectiveness of the prototype. I worked on designing the testing protocol in order to test our four main functional requirements, tunnel conflict, drill location, drill angle, and number of portals.

Bobby Oehrlein: As a Co-Leader of the Arthrex duplicate team, I was responsible for designing an existing Arthrex drill guide. This included working in Fusion 360 to design the parts, creating drawings for the parts and working with Scott, our shop contact, to ensure that the parts could be manufactured. This work was able to show me how a team project functions as I was able to understand the dynamics of having several subgroups. This semester I was able to build on my leadership skills as well as my project management abilities.

Lauren Schuster: Being a testing team co-leader allowed me to work with my teammates to plan out testing, design the testing setup, and test the prototypes. I was able to manage the budget for my team and work to realize and contribute to the overall ARID team development. Throughout this year I was able to grow as a leader and manager as well as learn about the design process first hand.

Zachary Fiske: As a co-leader of the testing team I worked closely with Nate and Lauren to design testing protocols, brainstorm creative solutions to increase testing fidelity, and perform tests on all prototypes. Throughout the year I also performed a variety of tasks including designing team logos, stakeholder outreach, literature review, communications, and other operations as necessary. Through this process I developed my team skills, engineering design skills, project management skills, and gained experience with conducting hands-on research.

0 Comments