The primary stakeholder involved throughout the beta prototyping phase was the machine shop. Both the thermal comfort and thermal storage teams consulted with the machine shop before ordering materials and beginning construction of many aspects of our final system. The machine shop also performed water jet cutting for the team, cutting holes for the copper tubes into the metal pieces that form the sides of our heat exchanger, and using other machinery to aid in assembling the transition piece.

Homeowners were the primary stakeholders of our overall project, but did not need to be involved directly during the design process. Our prototype was not created for one specific client but rather designed for a broader audience. Therefore, the information from our initial homeowner survey was sufficient to integrate homeowner feedback into our design. Design decisions were made with the homeowners’ priorities in mind, in which saving money was top priority. Therefore, we aimed to optimize energy efficiency and purchase off-the-shelf materials whenever possible. We also tried to use sustainable and durable materials so that the system could lead to long term savings. Because of these design decisions, our system will be the most economical for homeowners.

Near the end of the beta prototyping phase, the team decided that it was a good time to re-engage stakeholders we previously interacted with, in the earlier stages of our project. Ty Newell is an industry expert who is the vice president of BuildEquinox, a company which specializes in smart ventilation. He first introduced the team to the importance of thermal comfort as it relates to productivity. After pursuing a project with one primary goal being to maximize thermal comfort by allowing for zonal temperature control, we planned a follow-up interview with Ty Newell, with the goal of understanding if our project addresses the initial problem he presented to us as well as how we can best evaluate the efficiency of our system.

The following are some things we learned from the interview with Ty Newell:

- It might be difficult to get the required heat transfer capacity to both charge and discharge the PCM. It might be useful to experiment with mixing something into the PCM to change how it charges/discharges and the transition temperature.

- In terms of combining the thermal storage and thermal comfort elements, it might be difficult to get the PCM to be used for both heating and cooling because people have different temperature preferences depending on season.

- As we think about next steps and scaling our system up, we need to think about the capacity of our system. HVAC systems in schools, for example, can have four different running capacities which are achieved with three different fan speeds and two different compressor levels. The CERV system uses a reciprocating variable speed compressor and an inverter, which controls the compressor speed by regulating current.

The team also decided to plan an interview with an HVAC technician at Lafayette College, in order to discuss installation and maintenance of our system. Some questions and feedback we received include:

- We should consider the effect of the duct size on the number of PCM pipes required as this could become a more significant consideration in scaling up the system.

- A greater surface area for heat transfer would result in faster freezing and thawing, so it’s both a good and bad thing.

- If more dampers are closed, the pressure will be greater, which might not necessarily result in faster cooling for the one zone.

- We could consider installing a bypass duct, as sometimes we won’t want to use an hour to freeze PCM to get cold air; we just want the cold air right away.

- It might be useful to think about how the environment affects the system. For example, if it is installed on the roof, which is at a different temperature, how might this affect its performance.

- There could be a large amount of condensation on the heat exchanger as we are counting on the cold surface of the tubes cooling the warm air. In the future, we would likely want to do something to address this, by installing a plumbing trap or somehow routing the condensation back to the heat pump.

Finally, as previously mentioned, early in the fall semester, the team surveyed 43 homeowners about their experience with the existing HVAC systems in their homes, including their ability to keep their homes at comfortable temperatures in different times of year and any issues they have with window AC units. We had also previously asked about how willing they are to make changes to the system they currently have and what factors inhibit them from upgrading their systems. Now that we have just about completed construction of a system that should address many of their concerns, we resurveyed many of these same homeowners, providing an overview of our system and asking if their willingness to upgrade their current system has now changed, knowing the capabilities of our system, etc.

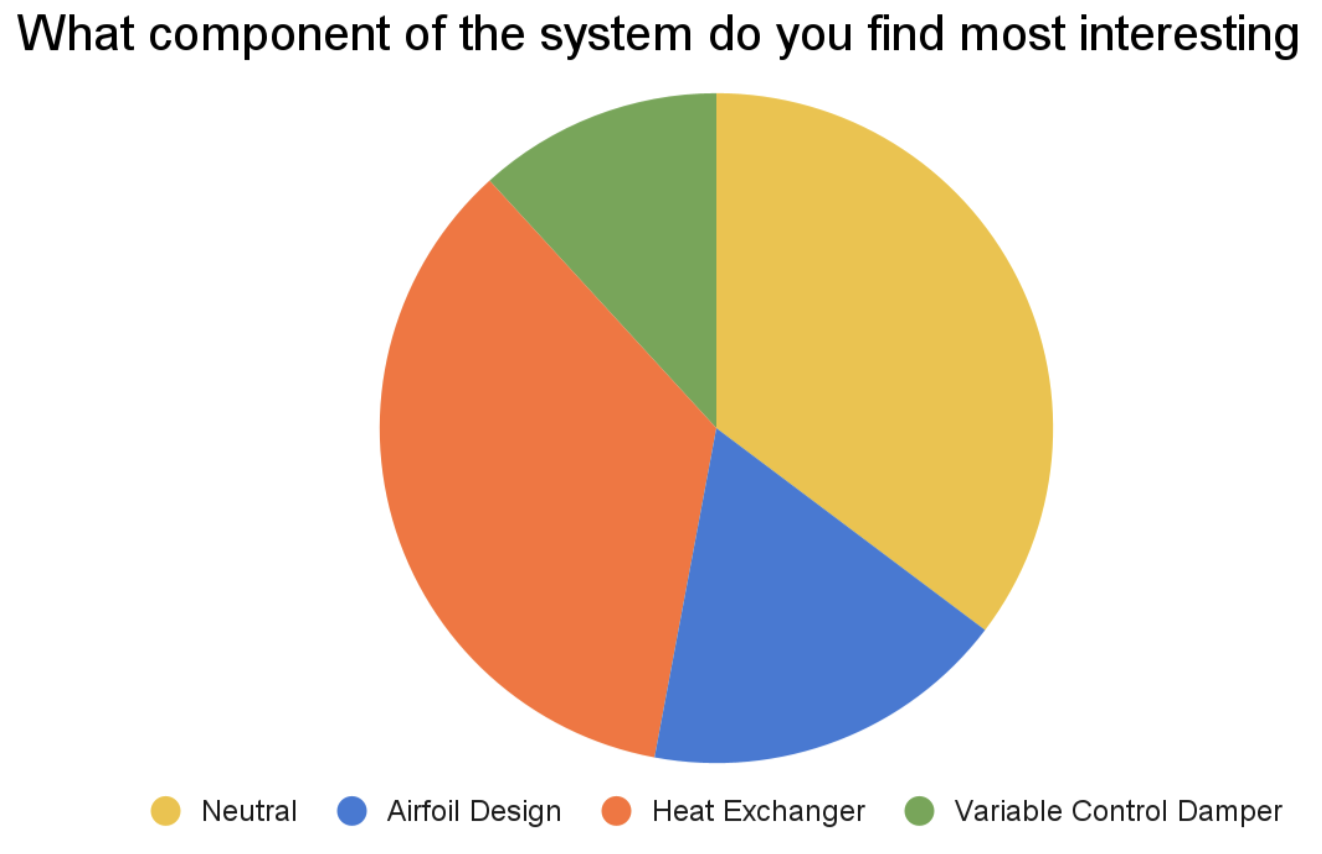

As shown in the below image, many of the homeowners we surveyed were either neutral in terms of the component of our system they found the most interesting or found the heat exchanger to be the most interesting component. When we previously surveyed homeowners in the fall, they seemed more concerned with the cost of their HVAC system as well as the comfort it provided them, but were less concerned with energy efficiency. Although a more energy efficient system can indirectly lower energy costs, it’s interesting to see that many of these homeowners are now more interested than they previously were in energy storage and reducing wasted energy, now that they’ve learned more about how we implemented those considerations into our system, through the heat exchanger.

Furthermore, of the homeowners surveyed, 76.5% indicated that after learning about our system, they are more willing to make changes to their existing HVAC systems, 76.5% value long-term savings over upfront cost of their energy systems, and 70% value using sustainable materials. Overall, it seems that after being made aware of the possibility of having a system that keeps them comfortable, is sustainable, and reduces long-term costs, homeowners are more willing to consider changing their current systems based on the options they now know are available and are less concerned with the upfront costs of a more energy efficient system due to the long-term savings they generate.