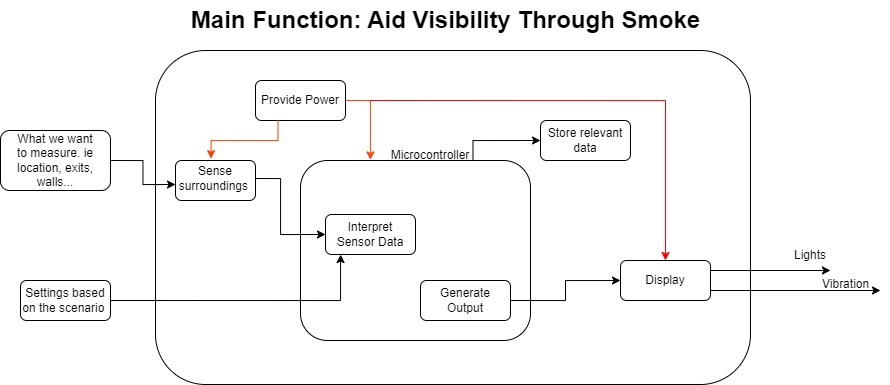

Functional Decomposition:

The main inputs of our functional decomposition are “setting of the scenario” meaning a smoke filled room, a building on fire, etc. Then we want to measure, i.e. the walls around the user and the distance between a solid surface, or the way traveled once entered the building. These then go into the composition, like what’s being measured is used to sense the surroundings. This data is then interpreted into the microcontroller. The data will then be stored, and a display made whether through the form of vibrations or of a light display. Inside the device the power will be provided by an internal power source which will power the micro controller and the display. The main function of the device should be to aid in navigation for firefighters throughout residential buildings. The thick smoke present within most fires makes this nearly impossible with the firefighter’s current technology.

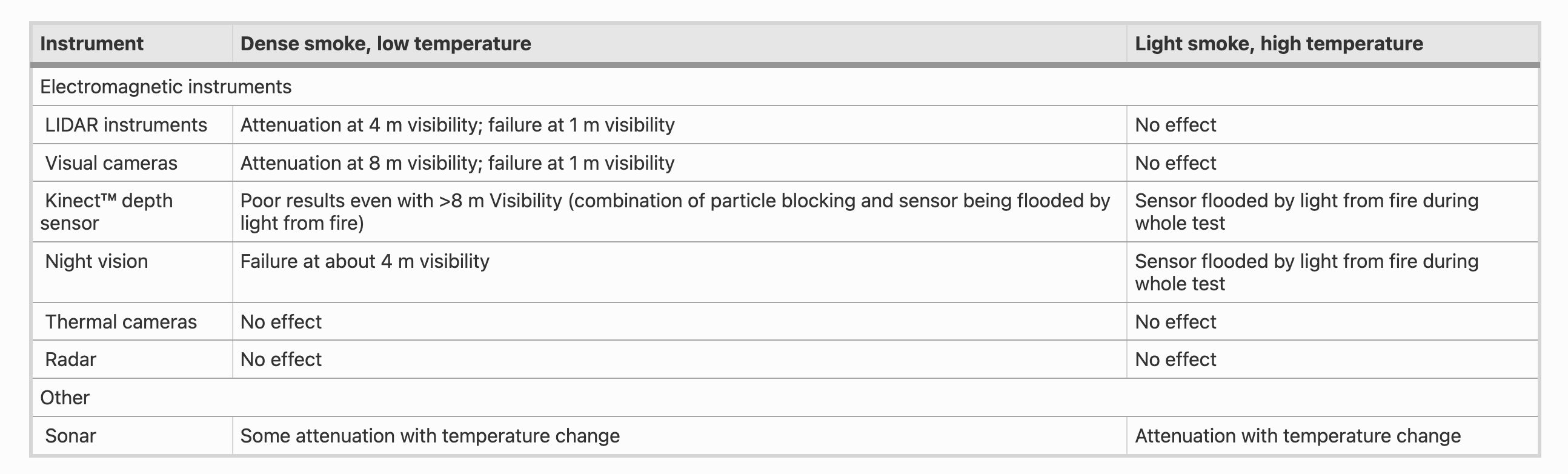

Table from: https://link.springer.com/article/10.1007/s10694-013-0356-3

Decisions to use ultrasonic sensors instead of LIDAR instruments were due to research inferring additional obstacles in the use of light-based sensing in smoke. The research suggested that LIDAR instruments would struggle in smokey conditions. Particles in the medium (the smoke) would obstruct the ability of most LIDAR systems to find any surfaces at any distance deemed desirable for the final prototype. Ultrasonic sensors on the other hand could, while struggling in thicker smoke, is capable of detecting solids. This then determined that the ultrasonic sensors would be the sensors used for the final prototype.

Prototype Description and Intent:

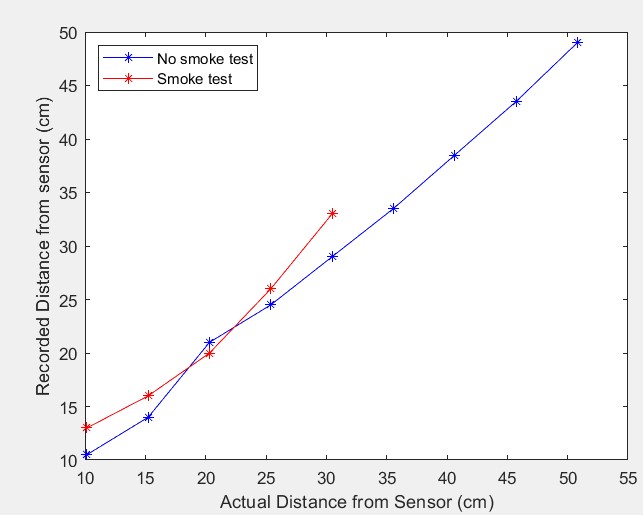

The alpha prototype mounted an ultrasonic sensor into an enclosed chamber to determine the accuracy of its distance measurements. The prototype was initially tested under two conditions: a setting void of smoke and a setting primarily composed of smoke. The intention of the alpha prototype was to determine how well ultrasonic sensors could “see” in a smoke-filled environment. Testing consisted of inserting 3-inch plane walls made of wooden tiles, carpet, plastic, and glass into the smoke chamber and having the sensor state their distances at different locations. This allowed the team to determine how well the sensor sensed the obstacles. The chamber without smoke was used as a baseline for the sensor because it would, theoretically, not be impaired. The alpha prototype consisted of the most cost-effective ultrasonic sensor available to the team. This, along with additional factors such as supplied power, may account for discrepancies between the sensor’s marketing description and the testing performance.

Evaluation Criteria and Results:

Tests were conducted using the prototype to compare the accuracy of measurements in both clear and smoky environments from various distances using multiple different materials. The values found by the sensor can then be compared to the actual distance measured with a tape measure.

Glass Results:

| Actual Distance (cm) | Measured With Smoke (cm) | Measured Without Smoke (cm) |

| 10.16 | 13 | 10.50 |

| 15.24 | 16 | 14 |

| 20.32 | 20 | 21 |

| 25.4 | 26 | 24.5 |

| 30.48 | 33 | 29 |

| 35.56 | Undetected | 33.5 |

| 40.64 | Undetected | 38.5 |

| 45.72 | Undetected | 43.5 |

| 50.8 | Undetected | 49 |

Stakeholder Involvement:

Due to the fact that our Alpha prototype focuses on testing how ultrasonic sensors perform in environments with varying levels of smoke, there was a large emphasis on the accuracy of the sensors themselves regarding obstacle detection, and not on their implementation. In our discussion of our upcoming steps during our Alpha prototype presentation, we decided that it would be most effective to reach out to firefighters during our Beta prototype, which will focus on implementing our sensors from the alpha prototype into firefighter equipment. So, we will definitely seek feedback from our stakeholders for the Beta prototype after verifying the performance of the sensor we plan to use.