WHAT IS AN ADIABATIC COMPRESSED AIR ENERGY STORAGE SYSTEM?

Click on the individual subsystems links to find out more about their designs:

Expander/Generator • Compressor/Pressure Vessel • Heat Exchanger

High-Level Process Overview

~This process is described under the assumption of ideal conditions~

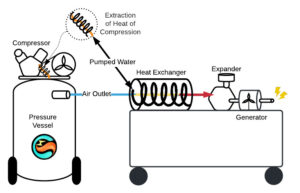

Compression Process:

- Air at ambient conditions enters a 2-stage compressor. During the compression process, the pressure and temperature of the airflow increase.

- The compressed air then continues to travel through copper piping until it is stored in a pressure vessel.

Charging Process: Compressor -> Heat Exchanger

- The heat transfer fluid, water, flows through copper piping that has been coiled around the copper pipes in order to maximize areas of contact. The heat generated during the compression process is transferred through the pipes, heating up the water.

- The water piping then travels through the thermal energy storage tank, transferring the heat a second time into stationary thermal energy storing fluid, water. The water remains stationary in a well-insulated storing unit, minimizing energy losses.

Discharging Process: Heat Exchanger -> Expander

- Once electrical power is needed, the compressed air (which has reached steady-state conditions) can be released. It then travels through the energy-storing unit and into the expander.

- As it travels through the energy-storing unit, heat from the stationary water is transferred back into the compressed air, increasing the expansion process temperature. This ultimately increases the power output.

Under ideal conditions, the entirety of the heat generated during the compression process can be stored in the energy storing fluid. This thermal energy can then be used to re-heat the air once the expansion process begins. Theoretically, no heat would be lost to the surroundings, and power output efficiency would be optimized.

Why Adiabatic?

A process is defined as Adiabatic when there is no heat transfer between the system and its surroundings.

For Simple-Cycle CAES system configurations, the heat generated during the air compression is released into the surroundings, wasting thermal energy. In an Adiabatic CAES system, the compression heat is stored in a thermal energy storage unit, and it is later used during the expansion process. Using the stored thermal energy drastically increases power output efficiency not only by increasing the temperature during the expansion process but also by doing so without the introduction of external heating methods. If instead of using the system’s stored energy the expansion process was heated by an external source, this would have to be factored into the system’s efficiency by adding an extra heat term to the denominator of the efficiency equation, resulting in a lower power output efficiency [1]. For more information on prior work done in the field as well as relevant technical concepts, feel free to explore the links below.

Literature Review • Technical Concepts

Metrics and Constraints

The following metrics and constraints apply to the entire system. For a more detailed breakdown in relation to metrics and constraints, see the individual subsystems by clicking on the diagram above.

Constraints

-

- The prototype must generate at least 1320 W of power. This is the power required to meet Level 1 EV charging requirements. In order for our prototype to meet the needs of our stakeholders, EV manufacturers and owners, power output must meet this threshold. A scaled up version of our prototype would likely meet higher EV charging levels.

- The prototype’s run time is longer than 30 seconds. Having a prototype that can run for more significant periods of time enhances the system’s modeling and demonstration capabilities.

- The system’s loudness while in operation is less than or equal to 85dBs. This is a safety consideration, exposure to noise over 90dBs for extended periods of time can lead to hearing damage. (OSHA Standard 1910.95 – Occupational Nose Exposure: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.95)

- The system’s design components are easily sourced, inexpensive, straightforward to assemble, and integrated with each other. Our prototype will serve as a model for a larger, utility-scale compressed air energy storage system. Because of this, we would like our prototype to be easily imagined and replicated on a larger scale. We, therefore, want the system to run on components that are accessible at larger pressure or power capacities (ie: larger pressure vessel and air motor) and are not uniquely fitted to our prototype’s scale.

Metrics

-

- Total round trip efficiency of 50 percent

- The constraints above also function as design metrics

Performance Considerations

- Power rating (MW)

- Energy/storage capacity (Wh): the max amount of stored energy that system can deliver

- Charge efficiency (%) stored energy/input energy

- Discharge efficiency (%) output energy/stored energy

- Round trip efficiency (%) output energy/input energy

- Mechanical Efficiency of Compressor

- Isentropic Efficiency of Compressor

Economic Considerations

- Power capital cost ($/W)

- Energy capital cost ($/Wh)

- Operating and maintenance cost ($)

Codes and Standards

We planned to follow ASME Power Test Code 53 Mechanical and Thermal Energy Storage Systems. This set of codes is still currently a draft, but they outline testing procedures for mechanical and thermal energy storage systems. The testing procedure describes putting a test boundary around the energy storage system to calculate power, energy, and efficiency.

Learn about the applicable codes and standards here.

Safety Plans

To prevent accidents from occurring, we put together a comprehensive safety plan detailing the risk factors that we planned to manage in our lab.

See our safety plan here.

Budget

We anticipated a preliminary budget of $3,000 and roughly three hours of manufacturing time in the shop.

See our updated budget breakdown here to see how it compares to our estimated budget.

References:

- Venkataramani, Gayathri & Velraj, R. & Viswanathan, Kishore. (2018). Harnessing Free Energy From Nature For Efficient Operation of Compressed Air Energy Storage System and Unlocking the Potential of Renewable Power Generation. Scientific Reports. 8. 10.1038/s41598-018-28025-5.