Expansion Design Considerations and Selection

Beginning design selection for the expansion device, we had to first consider our power output goals, as we aimed for the power output to reach at least that of level one electric vehicle charging. Level 2 charging was not safe for prototyping and we will have a team of chemical engineers joining us in the Spring to model a larger scale system. Level one charging requires a minimum of 110 Volts, 1320 Watts, and 12 amps. 1320 Watts is equivalent to 1.77 hp.

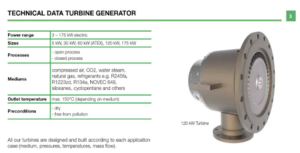

From research we found a turbine from a German company, Deprag, designed for green energy purposes. The turbine was designed to be highly efficient, but even the smallest model offered was not economical and cost around 17,000 euros. The turbine provided 5 kW of energy. While this was completely out of the question for a prototype, we learned about the system and began to find alternative ways to model a similar system using a separate air motor and generator.

Figure 1: Technical data sheet for turbine generator [1]

Smaller scale air motors produced by companies like Gast and Grainger offer power ratings ranging from 0.5 to 9.5 horsepower, creating high versatility toward application and economy. We performed calculations for air motors between 0.9 and 1.8 horsepower to determine the minimum amount of time that the motor could produce rotation from our stored energy. While larger air motors typically had greater power outputs, they required greater airflow and would therefore exhaust the stored air supply more quickly. We decided on a 1.8 hp air motor, which reaches just over the 1320 Watt threshold required for Level 1 EV charging. While the runtime of this motor is slightly less than that of the smaller air motors, it could be further increased by running the compressor during the expansion process, simulating a larger storage tank.

Smaller scale air motors produced by companies like Gast and Grainger offer power ratings ranging from 0.5 to 9.5 horsepower, creating high versatility toward application and economy. We performed calculations for air motors between 0.9 and 1.8 horsepower to determine the minimum amount of time that the motor could produce rotation from our stored energy. While larger air motors typically had greater power outputs, they required greater airflow and would therefore exhaust the stored air supply more quickly. We decided on a 1.8 hp air motor, which reaches just over the 1320 Watt threshold required for Level 1 EV charging. While the runtime of this motor is slightly less than that of the smaller air motors, it could be further increased by running the compressor during the expansion process, simulating a larger storage tank.

Figure 2: Turbine Air Motor [2]

Calculations

Note: In the equations below, ρ is the density of air in kg/cubic meter and V refers to the volume of air in cubic meters.

Below is a table describing the parameters of air inside and outside of the compression tank. The mass of air is the same compressed as it is expanded, but the volume is much larger at atmospheric pressure than at 175 psi.

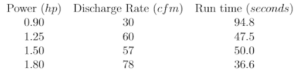

Below is a table for the various power ratings and maximum discharge rates of each air motor with their associated minimum run times. These were calculated using the equations from above.

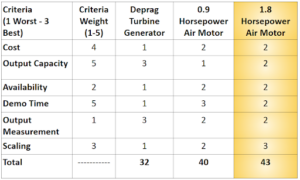

Design Selection Matrix

[1]

Get Turbine Generator – DEPRAG. https://www.deprag.com/fileadmin/bilder_content/emedia/broschueren_pics/emedia_druckluftmotoren/D6100/D6100en.pdf.

[2]

Amazon.com: Gast 4Z231 4AM-NRV-92 Rotary Vane Pneumatic … https://www.amazon.com/4Z231-ROTARY-PNEUMATIC-MOTOR-D614623/dp/B07D5HH4MB.