Introduction:

After many years, LaFarm got the approval and funding to create a greenhouse. The design and technology that was implemented made it highly efficient; the temperature monitoring system with an automatic venting system optimized temperature regulation. However, a few aspects of the project did not consider renewable technologies that would make the greenhouse carbon neutral. We identified that the two major aspects of the greenhouse that were not favorable included how it was getting its electricity and what fueled the air heating system used. Does our research build off residential and farming techniques to improve the efficiency of the greenhouse? In this section, we analyze some of these techniques to find a way to reach our goal of creating a carbon-neutral greenhouse.

Greenhouse Layout and design:

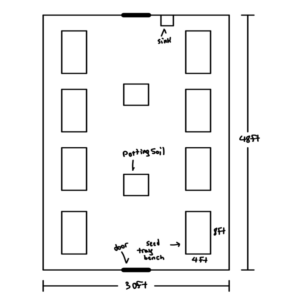

The size of the newly constructed greenhouse is 30ft x 48ft. The intended space is planned to be used for seed starting for not only LaFarm, but all members of the communities. The greenhouse is located between LaFarm’s current land plots and the Metzger Sports Complex (see figure #). It is located near a hill that, arguably, the greenhouse could have been built on to take advantage of some of the geothermal properties of the ground; allowing for the creation of storage. The proposed floor plan for the greenhouse is to have two rows of tables, one on each side of the greenhouse, allowing LaFarm volunteers and community members enough space to prepare and maintain seedlings. We assume that the work tables will be about four by eight feet in size to allow an adequate amount of seed starting trays to be prepared. We plan that about two rows of four tables will be placed in the greenhouse with two roughly four by four feet bins in the center of the greenhouse with potting soil storage. Each table will fit about sixteen seed starting trays (22 x 11x 2.5 inches in size). These have about 72 cells for seeds (cell seed starter tray (2016). This would require about 32 heating pads (48 x 20 inches in size) (48″ x 20″ seedling heat mat 2016)).

Figure T1 (Lafarm Greenhouse in final stages of construction, taken by authors)

Figure T2 (This is the rough floor plan of the greenhouse, drawn by authors)

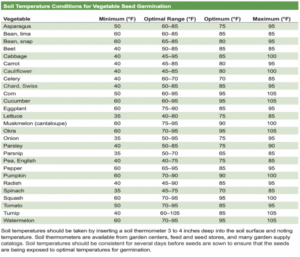

Our greenhouse plans also consider using heating pads placed right underneath the seed starting trays. This system is effective for seed starting because seedlings only need the dirt to be at the proper germination temperature. The air temperature could be much cooler, allowing us to concentrate the energy use where it would most effectively accomplish the goal. Combined with our proposed solar array, we could directly transfer the sun’s free energy to the seedlings via their soil. Heating mats are affordable, simple, and require no maintenance.

Figure T3 (Soil Temperature Conditions for Vegetable Seed Germination, Kemble & Smith, 2020)

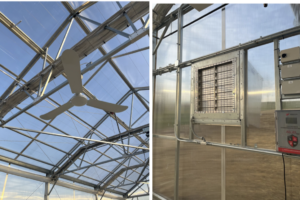

In greenhouses, shading can be utilized as a barrier to help keep plants from experiencing extreme temperatures, helping regulate the climate inside to optimize growing the seedlings (Hesham A. Ahmed et al., 2016). One way this beneficial tactic can be used is by adding a shade that would deploy a few inches from the greenhouse ceiling, allowing optimal shading control. This allows only the air between this shade and the greenhouse ceiling panels to warm up, acting as an air buffer between warmer weather outside.

The temperatures and extreme summer heat could be unbearable during the spring, and this shading could help reduce the temperature. The new greenhouse design also utilizes two ceiling fans and vertical venting vans, along with a section of the roof being able to articulate open, allowing the hot air to escape. These methods of moving air and shading allow for an overall lower cost in regulating the greenhouse temperature at LaFarm.

Figure T4,5,6(Figures above show the ventilation and shading systems in the greenhouse, taken by authors)

Solar Technology:

How does solar work?

We are all aware that the sun produces energy and light. We can also convert the sun’s energy release to create electricity. The main technology that can collect this electricity is solar photovoltaics (PV)(Solar Energy Technologies Office). They are widely used in residential buildings and commonly placed on roofs to help supplement houses’ energy use. The demand for solar has skyrocketed in the last few years, allowing improvements in efficiency and cost to make it a more viable solution than ever. Enough sunlight reaches the Earth daily to power the world for an entire year if collected.

Sunlight is made up of tiny packets of energy called photons. These related particles reach the semiconductors on the solar panels. The semiconductors on the panels have a positive and negative layer, creating a magnetic field. When the photons hit the cell, energy releases some electrons on the semiconductor material. This creates an electric current that is harnessed from wires connected to the positive and negative sides of the cell. Each solar panel is made from dozens of these cells. Each array is made from dozens of panels. Once you add up all the voltages together, you generate enough electricity that would be meaningful to power our electronics. Solar panels produce a clean source of electricity with no emissions or moving parts. They are also fairly easy to set up anywhere it’s needed. However, weather and topographical conditions can dramatically affect the solar array’s output. This can limit the locations where solar would make sense.

Additionally, our solar energy production would be tied to the local power grid system. This means that during the day, whatever energy was produced in excess would be put back into the grid, and we could be credited for this excess energy. In the case of the greenhouse, we must be able to power vents, fans, water heater, run irrigation, and power the monitoring system. To understand how many solar panels we would need to install, we first have to estimate the energy consumption of the greenhouse. Our rough estimates are shown below.

| System | Watt | Hr/Day | E/Day | E/Month | E/Y |

| Fans | 120 x 2 | 18 | 4320 watts | 129.6 kW | 1555.2 kW |

| Vents | 756 x 5 | 2 | 30,240 watts | 907.2 kW | 10886.4 kW |

| Irrigation | 10 x 24 | 3 | 720 watts | 21.6 kW | 259.2 kW |

| Thermostat | 100 | 24 | 2,400 watts | 72 kW | 864 kW |

| Water Heater | 8320 | .25 | 2,080 watts | 62.4 kW | 748.8 kW |

| Geothermal Heating | 200 | 24 | 4,800 watts | 144 kW | 172.8 kW |

| Only running part of the year about 3 month | |||||

| BioMass heating | 100 | 18 | 1,800 watts | 54 kW | 162 kW |

| Heating plant beds | 32* 100 | 12 | 38,400 watts | 115.2 kW | 3,456 kW |

| Total | 16,180 watts | 84,760 watts | 2,542.8 kW | 19,659.6 kW |

Figure T7 ( Energy usage per year estimated by authors)

We predict that the greenhouse would require about 19,659.6 kW of energy per year. With this estimate we predict that inorder to provide enough energy. Inorder to generate this amount of energy we predicted that it we would need about 1,200 square feet. This would be about 50 feet long by 25 feet wide(Solar calculator). This would be a ground array similar to the Metzgar Sports Complex proposal as Lafayette has plenty of space, and it provides easy access to the arrays.

Biomass (pellet) Technology:

The Biomass air heater utilizes energy-dense pellets in a chemical reaction of oxygen and biomass at a high temperature that produces heat, water vapor, ash, and CO2. The heat is then used to heat air next to the combustion chamber and pumped into the air vents heating the air in the building. This heating method allows us to reach the desired temperature inside the greenhouse with minimal energy, as most power is used to start the combustion cycle. We recommend this source of heating as a supplemental source because it could reduce the amount of work the geothermal system we also recommend would do.

Additionally, we could use the resources of the engineering department to create our biomass fuel production using food scraps and other organic material from LaFarm(Ciolkosz, 2010). We could have our mechanical engineers design the system for the pellets used at LaFarm. Using a biomass pell heater would be the best supplemental air heating solution as we know that the system would only use a few months out of the year, and the geothermal system would be used year-round to cool and heat the greenhouse.

(Example of biomass heater, archiexpo.com)

Geothermal Technology:

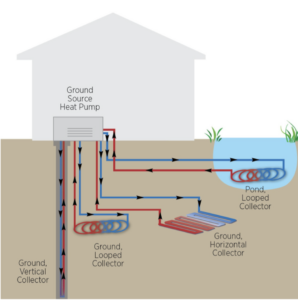

Geothermal heating and cooling utilize the ground’s constant temperature of about 54 degrees Fahrenheit when below about 10 feet. This consent temperature can be utilized to heat air in the winter or cool air in the summer. It is achieved by burying a loop of pipes around this depth and pumping water or antifreeze fluid through it. During the winter months, the air is generally cooler than the temperature below the ground. When the solution circulates through the piping, it absorbs the heat from the earth and is pumped back to the surface, and is transferred via a heat pump. Then the heating system warms the air even more before your ventilation system distributes the air throughout the space you are heating. Taking advantage of the earth’s temperature change allows less energy use to bring the temperature back to a comfortable level. During the summertime, the system works in reverse, moving the warmer fluid from the surface to below ground where the consent temperature of the ground can cool the fluid before bringing it back up to the surface. Also, saving how much is needed to spend on cooling the air.

When installing the fluid loops, there are two main methods. The first method is called a horizontal heat pump; it is closer to the surface but requires a lot of additional land. This heat pump distributes the piping horizontally in circular loops. It’s ideal for smaller buildings, typically residential homes with land and minimal requirements, compared to larger commercial buildings. A vertical heat pump which puts its piping deeper into the ground, takes up less space if the land is limited as it just puts the pipes deeper into the ground. This approach is more used with larger commercial buildings as they would need a lot more land for the piping, as they have to heat and cool bigger amounts of land.

Geothermal systems can be used anywhere as they take advantage of the constant temperature of the ground below the frost line. The frost line is where the water in the soil is expected to freeze below ground. Depending on the location where the system is installed, it can vary the system efficiency, giving different amounts of cost savings. The system’s efficiency makes it compelling as it’s easy to maintain. Still, the additional upfront costs of the system can be a point to deter, and it should be looked at as a system to help lower costs as it can not fully replace conventional heating systems. For LaFarm’s application, there may also be a need for a shed to store all the systems that are required to run the geothermal system.

(Geothermal diagram, office of energy efficiency and renewable energy)

Technical Analysis moving forward:

With all the research and efforts from previous capstones we believe that Lafayette College has made the steps in the right direction with building the greenhouse. We just need to keep pushing forward in our efforts to create a carbon neutral campus with making the greenhouse also carbon neutral. We laid out the technologies our group has deemed to be most effective to reach that goal. We have gained input for Farmer Josh and his experience in running other successful farms. We have given a preliminary estimation of the demands of the greenhouse as of this being written we do not have accurate energy demands of the building. Ideally the next group would be able to give a more detailed report on what the actual energy demands are of the greenhouse with it finally in operation. Given engineering studies limited knowledge in complex fields like thermodynamics it would also be helpful to seek assistance in determining a more accurate model of a geothermal system to support the greenhouse. Additionally with limited information on the greenhouses automation system, further analysis would be required to know how big of an impact it would have on the greenhouses efficiency.

Hopefully this can be a model for what the future of small agricultural college farms could look like.

To read about the economic context of this work, please follow the link here.