The bioremediation process that should be applied to the Easton Iron Works property is classified as “In Situ” because the focus is below ground in the soil or groundwater. In Situ bioremediation of groundwater has become an increasingly popular technology for contaminated site treatment because of its relatively low cost, adaptability to site specific conditions, and efficacy when properly implemented (Introduction to In Situ Bioremediation of Groundwater 2015). Bioremediation is “an engineered technology that modifies environmental conditions (physical, chemical, biochemical, or microbiological) to encourage microorganisms to destroy or detoxify organic and inorganic contaminants in the environment” (Introduction to In Situ Bioremediation of Groundwater 2015). The history of bioremediation practices extends from the mid-1800s with biological treatment of domestic wastewater to more recent decades of land treatments to treat oil and petroleum waste by aerobic biodegradation (Introduction to In Situ Bioremediation of Groundwater 2015). The technologies of the past have been made possible by overall technological advancements which impact all of society and new knowledge and research conducted on environmental remediation in recent years.

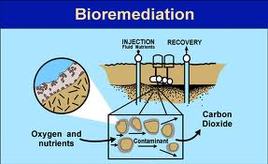

Figure 2.1: Graphic displaying the basic process of bioremediation

Bioremediation can be aerobic or anaerobic and it requires appropriate levels of water, oxygen, heat, and nutrients. (Goldie, 2012) The process of bioremediation is depicted in Figures 2.1 and 2.2. First, microorganisms go into the soil. Then, they digest contaminants and convert them into carbon dioxide and water. Finally, the carbon dioxide and water emissions are released from the soil in a gaseous state. The entire process is relatively quick, painless, and extremely cost effective.

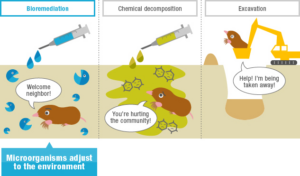

Figure 2.2: Graphic displaying the basic process of bioremediation

The Bushkill Creek being in the vicinity of the Easton Iron Works site provides a huge advantage for successful bioremediation. The Bushkill Creek is already a resource for so many living things. During the bioremediation process, it can help facilitate its own decontamination. Bioremediation is successful in mitigating contaminants in both soil and water. (Goldie, 2012) The microorganisms in the soil at the Easton Iron Works site can use the nearby water source as a form of nutrients. For bioremediation to be successful, the microorganism in the soil and groundwater must be active and healthy. The contaminated runoff from the groundwater at the Easton Iron Works site would no longer plague the Bushkill Creek because of the bioremediation taking place.

While all of this information is extremely positive towards mitigating contaminated groundwater and cleaning up the local environment, it is important to remember that different microorganisms mitigate different types of metals and compounds. Also, different species of microorganisms thrive under different levels of optimum conditions. (Goldie, 2012) Fortunately, human interaction can help provide an optimal environment for microorganisms to thrive. The best conditions for microorganisms largely depend on whether the microorganism is indigenous or exogenous. (Goldie, 2012) An indigenous microorganism is native to a given site. Human interaction would probably not be desperately needed to create a thriving environment for the microorganism. The addition of nutrients to soil and the proper maintenance of normal soil temperature and moisture content does not hurt in ensuring a good environment for the little microorganisms. and However, exogenous microorganisms are needed for bioremediation that were not previously at the site. When selecting an exogenous microorganism for bioremediation, a thorough amount of background research and human interaction must occur to create an environment in which the microorganisms can develop. If the proper steps are not taken to ensure the exogenous microorganisms can live, then bioremediation will not occur.

The time table of the bioremediation process is site specific. There are multiple factors that contribute to the successfulness of bioremediation, and the efficiency of the bioremediation process. Some of the factors include the type of contaminant being mitigated as well as the concentration of the contaminant. Geographical factors include the size, terrain, and depth of the polluted areas. (Goldie, 2012). For instance, dead soil with no existing microorganisms, will have to be fertilized and brought out of its format state before exogenous microorganisms can be deposited into the ground. With all factors considered, bioremediation is a process that can take a few days or many years. However, the important thing to remember is although the clean up may take a long time, the solutions are long lasting and sustainable.

Figure 2.3: A light-hearted depiction of different mitigation techniques

Bioremediation is a fantastic solution to the problem of contaminated groundwater at the Easton Iron Works site. Not only is bioremediation cost effective and efficient, but it promotes environmental sustainability. There are many ways to fix contaminated groundwater. As you can see in Figure ?, three examples of environmental cleanup include bioremediation, chemical decomposition, and excavation. Only one solution allows for environmental sustainability. Microorganisms coexist with other larger organisms and allow for the cycle of life to continue. Bioremediation is not intrusive to the environment because of the microorganisms ability to coexist with other organisms.

Chemical deposition is a non-natural mitigation technique that does not coexist with other organisms. While chemical decomposition may be helpful in mitigating groundwater contaminants, there could be side effects to other organisms in the area. For instance, groundwater contamination may no longer exist at the Easton Iron, but chemical runoff in the Bushkill Creek could cancel out all of the efforts made at the site.

Excavation is the physical removal of contaminants from the groundwater at the site. As effective as it may be in procuring a remedy for the problem, there are no boundaries to its destruction. The contaminants in the groundwater would be displaced, but so would every living organism in the area. One problem would be solved, but more problems would arise as a result. Therefore, the solution would not be defined as sustainable. Bioremediation’s ability to create a solution to the problem without creating other problems in the long term makes it the most sustainable solution of the three.

One of the most vital pieces of cleaning the contaminated groundwater at the Easton Iron Works facility is the planning that occurs before the execution of the environmental cleanup. Mitigation can be a very complex concept to plan. Many variables need to be accounted for, but the primary variable is the type of metal contaminants that needs to be mitigated. Luckily, there is no shortage of mitigation techniques, but that creates another problem in itself. There are multiple mitigation solutions for each type of metal and every metal combination that one can imagine. Therefore, it is essential to have a plan and goals set before the project starts to minimize confusion and complexity. The Federal Emergency Management Agency (FEMA) created a five-step guide to developing a mitigation strategy. This strategy applies directly to the Easton Iron Mills project, and it will, hopefully, be the guideline to starting a project that ends with a sustainable cleanup.

FEMA Step 1: Validate Mitigation Goals (FEMA, 2016)

How It Relates to Easton Iron Works: FEMA emphasizes creating step-by-step goals to be achieved throughout the project. This allows the stakeholders and planning team to quantify their success and determine how well they are sticking to schedule. When creating mitigation goals, FEMA offers the acronym SMART as a guideline. SMART stands for Specific, Measurable, Achievable, Realistic, and Time-Bound. Those five criteria should be kept in mind when creating goals along the way of a mitigation project. Unfortunately, there is not much raw data available on groundwater contamination at the Easton Iron Works site. This is problematic because it prevents a planning team from creating goals with respect to any of the five criteria. In order to create specific and realistic goals, more information needs to be attained at the Iron Works site. Before any goals are created, the City of Easton should highly consider testing the groundwater to understand exactly what heavy metals and other contaminants are polluting the groundwater. A groundwater test is relatively easy to obtain, all the City of Easton needs to do is contact the Pennsylvania Department of Human Services. The Human Services Department will be able to refer the City of Easton to a certified laboratory that can administer an accurate test. (The Groundwater Foundation, 2020) This knowledge will be exponentially important in helping create a mitigation plan, complete with goals for the project.

A preliminary test allows for a plan of action to be specific because the proper mitigation technique will be used to counter the known contaminants in the water. The goals and plan of action will be measurable because there will be numbers and data to serve as a foundation to improve upon and gauge the successfulness of the project. The final three letters of the acronym go together. If there is a base layer of data, and a specific knowledge of what is contaminating the groundwater, the goals of the project will undoubtedly be extremely more realistic and achievable while also having a better understanding of how long the project will take.

An excellent example of a plan to be set within the guidelines of SMART occurred in Lakewood, New Jersey, in 1994. The project used bioremediation techniques to reduce total petroleum hydrocarbon at a site by 99.8% in four months. This is a completed project goal and not a goal planned to be completed in the first week, but it does meet all the criteria of SMART. It was specific because the known contaminant that needed to be countered by bioremediation was petroleum hydrocarbon. The goals were measurable which was made evident by the data showing a 99.8% reduction in petroleum hydrocarbon. It was time-bound as shown by the four month time table it took to complete the project. Finally, the project was clearly achievable and realistic because the end result was a complete success.

FEMA Step 2: Review, Evaluate, and Update Mitigation Actions (FEMA, 2016)

How It Relates to Easton Iron Works: This step in the FEMA plan emphasizes the importance of staying vigilant and constantly evaluating possible changes that may occur on the site. Even the best mitigation plans with the most stable conditions are highly subject to change. It is crucial for the planning team to continually make risk assessments and identify any new threats or hazards. Should any changes or hazards be identified, the planning team must evaluate their current plan and be willing to update their strategy and overall project goals. Identifying problems could cause new techniques to be more expensive or add months or years to the project. However, it is imperative to be able to work while understanding the risk of the project and being able to update mitigation actions quickly if necessary.

FEMA Step 3: Develop New Mitigation Actions (FEMA, 2016)

How It Relates to Easton Iron Works: If problems are identified or more data comes to light, it might be necessary to develop new mitigation actions. This might add more expenses and time to the project, but it allows for the most sustainable solution to be offered to the problem. An example of a change that could occur at the Easton Iron Works site is discovering a metal that was not in the original mitigation plan. For instance, if the decided remediation treatment was Capping, but new, additional information revealed that Zinc and Cadmium were also contaminating groundwater, a new technique would have to be adopted. Capping is the use of a natural soil cover to stop the spread of contamination and it is not effective in mitigating Zinc and Cadmium, so an update to the mitigation plan would be required. This update to the plan would have to be a more effective remediation technique for Zinc and Cadmium, such as biological treatment. Biological treatment includes remediation techniques such as mycorrhizal mitigation. The best techniques for each contamination comes from data displayed in Figure E which will be displayed later in the paper.

FEMA Step 4: Develop the Details and Prioritize Mitigation Actions (FEMA, 2016)

How It Relates to Easton Iron Works: There is not much detail surrounding the Easton Iron Works remediation project. There is some basic knowledge regarding what type of hard metals might be contaminating the groundwater, but the specifics are unknown, which makes it tough to select a proper mitigation technique. For a group of engineers working on this project, it is common knowledge that the heavy metals on the periodic table are Lead, Cadmium, Arsenic, and Mercury. Figure E provides a mitigation solution for each hard metal and also includes techniques to use for Zinc and Copper as well. However, the lack of knowledge of exactly what type of heavy metal is contaminating the groundwater at the Easton Iron Works plant makes it impossible for a definite mitigation technique to be chosen. This lack of knowledge is why it is so crucial for the City of Easton to run a preliminary groundwater test at the site to confirm what contaminants are in the groundwater. FEMA addresses prioritizing different details such as timeline and completion date, goals addressed, hazards addressed, available resources, etc. However, detailed information has not yet become available. Until the information with definitive results of what is polluting the groundwater at the Easton Iron Works site becomes available, it is not easy to distinguish priorities for moving forward with the site’s mitigation.

FEMA Step 5: Identify Funding Sources (FEMA, 2016)

How It Relates to Easton Iron Works: The City of Easton has purchased the Easton Iron Works lot, and Easton’s Public Works department has received a maximum grant of $1 million from the Industrial Sites Reuse Program (ISRP). The funding is entirely dedicated to a remediation of the Easton Iron Works site. The amount of funding has been identified; however, how the budget will be distributed is undecided. Hopefully, the Easton Public Works Department will decide to allocate the $1 million grant by allowing more money to higher prioritized mitigation actions and less money to lower prioritized mitigation actions.

The biggest roadblock in the project at the moment is the lack of detail with respect to what contaminants need to be mitigated in the groundwater. There is some knowledge available, such as common knowledge of the heavy metals, that make speculation and planning somewhat possible, but it does not allow for a concrete plan to be put in place. The lack of knowledge about the contaminants in the ground water at the Easton Iron Works site calls for the preliminary groundwater surveillance test as soon as possible. The surveillance test is the first step towards physical progress of cleaning up the site. There is so much information about bioremediation and different biomitigation techniques available. However, none of this information can be put to good use until the exact contaminants and their concentrations are discovered. As detailed information becomes available, a project will be put in place to remediate the Easton Iron Works site based on FEMA’s five steps for mitigation planning.

There are a number of different approaches to the environmental remediation process at the Easton Iron Works property depending on the site characterization. As previously mentioned, this remediation project must be in accordance with Act 2 of the Remediation Process. Site characterization is defined in Act 2 as a “description of contaminated media, including geology and chemical and physical characteristics, that affect movement of regulated substances in environmental media” (Department of Environmental Protection, 2019). The site characterization of the Easton Iron Works property will determine which of the potential remediation technologies will be best suited for this project. The specific data on which metals are present at the Easton Iron Works property are currently unavailable, but based on public environmental data we can ascertain the most likely substances present at the former iron company. The Ground-Water Remediation Technologies Analysis Center (GWRTAC) at Carnegie Mellon University has found that the most common metals found in the ground at contaminated sites are lead, chromium, arsenic, zinc, cadmium, copper, and mercury (Evanko & Dzombak, 1997). Because it is likely that these metals are some of the metals present in the ground at the Easton Iron Works site, we will investigate different solutions for a variety of these metals.

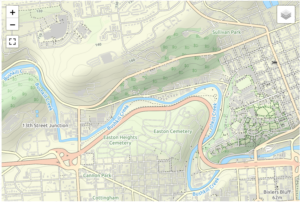

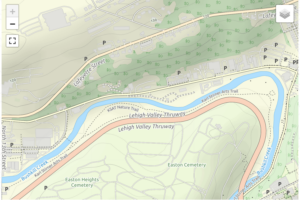

Not only does the type of metal present determine the best potential remediation technology, but also do the subsurface conditions. These soils can be defined as contaminated soils, sludges, wastes, or debris (Evanko & Dzombak, 1997). The Easton Iron Works property is a site that demonstrates direct ground-water contamination. In order to make the best decision of which remediation technology to use at the Easton Iron Works site, we will also need to know the span of contamination across the site and potentially beyond its barriers. This type of information can be predicted based on the topography of the area around the source of groundwater contamination because groundwater and its contaminants tend to follow the path of topographical lines (Getting Up to Speed: Groundwater Contamination 2015). Figure 1a and Figure 1b show the topographic map of the area around the Easton Iron Works property at different zoom levels. From the topographic map of the area, it is predicted that the flow of contaminants from the Easton Iron Works property could potentially exist along the lines that pass through the property which includes points of contact with the Bushkill Creek. This is problematic for many reasons including the fact that the Bushkill Creek is a part of the Delaware River Watershed, which is a source of drinking water for both people and wildlife (Watershed Watershed Program page Description). Contaminant concentrations can be measured directly in metals-contaminated water (Evanko & Dzombak, 1997), therefore if the data is not yet known, we could potentially collect water from the Bushkill Creek to determine the presence of metal contaminants.

Figure 4.1

Figure 4.2

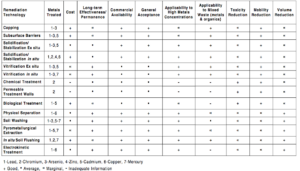

The general approaches for groundwater and subsurface environmental remediation include isolation, immobilization, toxicity reduction, physical separation and extraction (Evanko & Dzombak, 1997). Of these general approaches, there are existing remediation technologies that could be applied to the Easton Iron Works Property. Isolation technologies inhibit the movement of contaminants by containing them within a designated area (Evanko & Dzombak, 1997).

One potential isolation technology that could be applied at the Easton Iron Works property is Capping, which targets lead, chromium, and arsenic concentrations. Subsurface Barriers is a similar isolation technology, but it also treats cadmium concentrations. Capping and Subsurface Barriers are methods that would be most successful when paired with additional remediation technologies because although they are cost effective, generally accepted, and reduce mobility, they fail on the long term scale because they do not reduce toxicity or volume (Evanko & Dzombak, 1997). Immobilization methods are similar to isolation methods in that they successfully reduce mobility but not toxicity or volume. However, the advantage of immobilization methods is that they are more cost effective, can be applied to high metals concentrations, and have a better

Figure 5: A depiction of the plethora of remediation technologies and how effective each technology is in many distinct variables

long term effectiveness (Evanko & Dzombak, 1997). Toxicity reduction methods include both chemical and biological treatment technologies. Chemical treatment only treats chromium of the most common metal contaminants. Chemical treatment has average permanence, commercial availability, and general acceptance (Evanko & Dzombak, 1997). Biological treatments could potentially be more advantageous in terms of the Easton Iron Works environmental remediation project because they treat a wider range of contaminants — lead, chromium, arsenic, zync, and cadmium– and are more cost effective (Evanko & Dzombak, 1997). However, biological treatment methods have marginal permanence and applicability to high metals concentrations (Evanko & Dzombak, 1997).

Next: Economic Context (EIM)