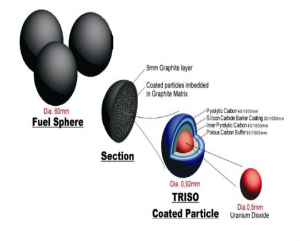

The technology for pebble bed modular reactors (PBMR) was originally developed by Professor Rudolf Schulten of Aachen University in Germany in the late 1950s.[1] The PBMR was part of the fourth generation of nuclear reactor design. PBMRs are an example of high-temperature gas-cooled reactor. PBMRs are capable of operating at higher temperatures than traditional nuclear reactors and thus increase the overall efficiency of energy production.[1] In addition PBMRs use tristructural-isotropic (TRISO) sphere as the fuel source for the fission reaction. The TRISO sphere are composed of uranium oxide kernels that are surrounded by four layers of isotropic materials as shown below.[3] Each sphere has a graphite coating that can be used as a neutron moderator in the reactor.

The main purpose of the isotropic coating is the isolate the radioactive fission products and increase the structure integrity of the sphere under extreme heat.[3] The nuclear pebbles are roughly the size of a tennis ball and weight approximately eight pounds. Much like traditional reactors, nuclear pebbles are contained within the reactor vessel, which is housed in a large containment building. [3] The energy production process is also similar to traditional nuclear reactor design. In this case, inert helium gas is used as the cooling agent and working fluid which is heated by the nuclear reaction to run a turbine.[1]

What is unique about the PBMR is that the pebbles circulate through the reactor at approximately 5 times a year.[2] As a result the process can operate continuously and there is no need for a month long shutdown and start up. In addition since helium is chemically inert there is no risk of steam explosion like in traditional power reactors. Most importantly are the inherit safety features that are present in the PBMR design. In particular the spherical shape of the fuel source, and its proximity to each other within the reactor produce a strong Doppler effect. The Doppler effect produces a negative feedback loop that controls the overall reaction. As the reaction proceeds more heat is released by fission. As the temperature increases, uranium atoms vibrate faster and faster and release a wider spectrum of neutron speeds. The faster the atoms move the harder it is for the neutrons to absorb and react with the remaining uranium, as a result the overall reactor power decreases. In addition each pebble also has a relativity low fuel density when compared traditional reactor rods which enhances the overall negative feedback.[3] The inherit safety system present in the system can be seen in the video below.

Risks

Despite the improved safety of PBMRs in comparison the traditional nuclear reactors, there are still a few risks associated with the process. In particular, since each nuclear pebble is coated in graphite there is the possibility of combustion in the presence of oxygen.[1] In an effort to minimize this problem PBMRs are purged of oxygen before operation. Another problem related to nuclear energy is the production of nuclear waste. Due to the geometry of the particles, a large volume of nuclear waste is produced during the operation of PBMRs, thus storage of used reactor pebbles has become a problem.[3] Additionally, the nuclear pebbles are more difficult to repurpose than traditional reactor rods due to the many layers of construction. Thus it is difficult to reuse the waste for nuclear weapons or other applications.[1]

Future

A few nations have experimented with PBMR technology including Germany, United States, China, and South Africa.[2] In particular, South Africa has attempted to build a PBMR for commercial use as a part of their sustainable energy policy, however they have run into difficulties due to technical problems and lack of funding. In China however recent developments have been made to increase domestic nuclear energy production. In particular China plans to build and additional 50 nuclear reactors in the next 10 years. Additionally, a test pebble-bed reactor has been operating for over 10 years now in Tsinghua University north of Beijing. Furthermore the Chinese have already begun construction of the first commercial PBMR in the Shandong Province.[4]

(Composed by Ivan Basurto, Edited by Becca McIver & Dan Kervick)

References

1. Koster, A., HD Matzner, and DR Nicholsi. “PBMR Design for the Future.” Nuclear Engineering and Design 222.2-3 (2003): 231-45. Print.

2. Emily Grubert, Brian Parks, Erich Schneider, Srinivas Sekar. “Pebble Bed Modular Reactors Vesus Other Generations Technologies: Cost and Challenges for South Africa.” Proceeding of Global 2011 (2011): 1-8.

3. Reitsma, Frederik. The Pebbel Bed Modular Reactor Design and Technology Featuers . Johannesburg, South Africa: IAEA Interregional Workshop, 2011.

4. [Anonymous]. “US and China to Combine Forces to Develop Pebble Bed Reactors.” Professional Engineering 16.20 (2003): 8- Print.