What resources does biofuel rely on and what kind of energy does it produce?

Biofuel production relies on the availability of domestic crops, called biomass. The natural oils present in the selected biomass products can be synthesized into a fuel that can be used to operate an automobile. Sugar and starch crops are fermented to produce ethanol, comparable to petroleum. Biodiesel is extracted from soybeans and grass. The predominant crops used are corn and soybeans in the production of ethanol and biodiesel, respectively. In order to run a car on ethanol, it’s necessary to make alterations to the engine. However, a car with diesel engine already in place is capable of operating on biodiesel without any modifications to the car.

How does biofuel work?

Ethanol

Cars are currently capable of running on ethanol, and have been since 1907. Henry Ford’s Model T was a flex-fuel vehicle that was designed to operate on pure ethanol. Currently, vehicle manufacturers offer flex-fuel vehicles designed to run an any type of ethanol blend for sale on the market. The gasoline can be characterized by the percentage of it which is ethanol, with E5 and E10 representing 5 and 10 percent blends with gasoline. Blends on the low end such as E5 and E10 can be used in almost all IC engines while higher blends such as E85 require a flex fuel engine.

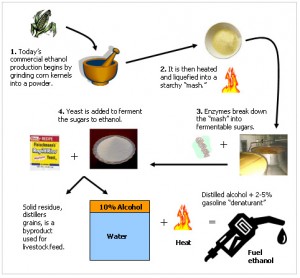

Ethanol is produced by converting sugar into alcohol. Dependent on the treatment of the grain, the production of ethanol can be classified as either dry mill or wet mill. A diagram of the process is displayed below.

Dry Milling

Dry milling involves grinding the entirety of a crop into flour without separating the various components within the grain. Then, the ground up product is mixed with water to form a mash. Enzymes are added to convert the starch in the mash to sugar.Next, the mash is cooked at high temperatures to reduce the presence of bacteria. The mash is then cooled and transferred to a location to be fermented and yeast is added to begin the process of converting sugar to ethanol and CO2. This process takes approximately 2 days. After the fermentation process is completed, the ethanol is blended with natural gasoline and can then be shipped for sale.

Wet Milling

Wet milling involves soaking a crop in a combination of water dilute sulfurous acid for 2 to 3 days. This process is called steeping. Then the corn oil is extracted and the remaining fiber, gluten, and starch are separated. The starch is then fermented into ethanol in a process similar to dry mill fermentation.

Ethanol contains less energy per gallon than gasoline so it has a lower fuel economy than gasoline, but does reduce greenhouse gas emissions by up to 52% compared to the production and use of the same amount of gasoline.

Biodiesel

Biodiesel is capable of being immediately input as the working fluid to any diesel engine. A mixture of biodiesel and conventional diesel can be used at any percent composition ranging from 0 to 100% biodiesel.

Biodiesel is produced through a process called transesterification which involves reacting an alcohol with either a fat or oil in the presence of a catalyst. This process is much simpler than the manufacturing process for ethanol. The biofuel refineries must produce a product that satisfies the specifications within the ASTM D6751 which outlines a safe composition of biodiesel to be used in a standard diesel engine.

An engine using some mixture of biodiesel would run the same as one running on conventional diesel with several slight variations. At very low temperatures the biodiesel tends to form clumps which can clog fuel lines and filters, leading to a lower performance than conventional diesel. The presence of oxygen in the biodiesel mixture reduces the carbon emission, but also tends to increase the nitrogen oxide emissions.

State of Biofuels

Ethanol currently accounts for more than 90% of the total biofuel usage, with the United States and Brazil as the world’s leading producers. Biodiesel is used to a much lesser extent, with Germany leading the international production market. Demand for biofuels is expected to increase in the future which leads to a struggle over land availability. As food demand is also expected to rise, there will be conflict over whether land is to be used for food or biofuel crop production. This leads to the genesis of biofuels not derived from food crops, or “2nd Generation” biofuels. These biofuels come from the processing of grasses and forest residues and do not compete with the arable land needed to grow food crops. While this new generation of biofuels is still being developed, it has become clear that just switching to all “1st Generation” biofuels will not be an adequate solution to the global energy crisis.

Primary Author: Harrison Congdon, John Marshall

Resources:

- http://www.ethanolrfa.org/pages/ethanol-and-engines

- http://www.dec.ny.gov/energy/44157.html

- http://www.energyfuturecoalition.org/biofuels/fact_ethanol.htm

- http://www.ethanolrfa.org/pages/how-ethanol-is-made

- http://www.biodiesel.org/what-is-biodiesel/biodiesel-basics

- http://www.afdc.energy.gov/fuels/biodiesel_production.html

- “IEA Energy Technology Essentials.” International Energy Agency. January 2007. http://www.iea.org/techndfno/essentials.pdf

- http://www.eia.gov/oiaf/analysispaper/biodiesel/

- http://www.afdc.energy.gov/fuels/ethanol_benefits.html