A major problem experienced by transportation planners wherever space is limited is parking. As transportation becomes easier and more and more people use their vehicles to get around, there has to be space to store these vehicles when not in use. The typical solution is to build a parking lot, however when space is limited this is rarely efficiency enough. A better choice is a conventional parking garage; however their efficiency is limited by the space that needs to be left for cars to make their way in and out. The solution to this issue has been the creation of automated parking systems (APS).

A major problem experienced by transportation planners wherever space is limited is parking. As transportation becomes easier and more and more people use their vehicles to get around, there has to be space to store these vehicles when not in use. The typical solution is to build a parking lot, however when space is limited this is rarely efficiency enough. A better choice is a conventional parking garage; however their efficiency is limited by the space that needs to be left for cars to make their way in and out. The solution to this issue has been the creation of automated parking systems (APS).

History

Automated parking was first constructed in 1905 in France, however the technology did not see significant usage until the 1970’s. These early systems were prone to mechanical failure and usually increased the amount of time required for drivers to park and retrieve their car. Japanese builders constructed some of the first and most successful systems during that time, as they worked to make the most of the small land area they had available. Interest in the US was limited until late in the 1990’s when the technology had developed enough to lower the likelihood of mechanical errors. In addition to being more space-efficient, these new systems also had a number of other benefits such as keeping the parked vehicles more secure, and protecting them from damage from careless drivers. One example of a modern automated parking system can be seen in Philadelphia, where designers have created an extremely efficient system to serve their parking needs.

While the concept still feels bizarre to me, I am sure that parking systems such as this will see more and more usage as development continues and land becomes more and more valuable, especially in congested cities such as New York.

Sources:

- http://en.wikipedia.org/wiki/Automated_Parking_System

Images:

- http://en.wikipedia.org/wiki/File:SDOT_R7-108P.svg

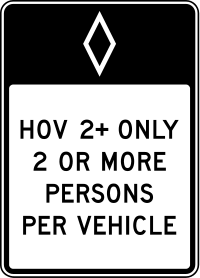

One interesting method for reducing congestion on heavily travelled highways is the use of a High Occupancy Vehicle lane, or HOV lane. These lanes typically require a minimum of two or three occupants in the vehicle, which encourages carpooling and decreases the total load on the roadway.

One interesting method for reducing congestion on heavily travelled highways is the use of a High Occupancy Vehicle lane, or HOV lane. These lanes typically require a minimum of two or three occupants in the vehicle, which encourages carpooling and decreases the total load on the roadway.

Our recent discussions of queuing in class have made me think a lot more about examples of queuing within transportation systems we frequently use. One queuing-related technology that is especially interesting to me is E-ZPass. As you probably know, this is an electronic toll collection system used throughout the northeast which relies on wireless technology to read transponders placed in cars through the toll plaza. Conventional E-ZPass installations have been very successful at decreasing wait times at toll plazas, with further decreases in congestion possible through the use of high speed E-ZPass lanes, which can collect fares at near highway speed.

Our recent discussions of queuing in class have made me think a lot more about examples of queuing within transportation systems we frequently use. One queuing-related technology that is especially interesting to me is E-ZPass. As you probably know, this is an electronic toll collection system used throughout the northeast which relies on wireless technology to read transponders placed in cars through the toll plaza. Conventional E-ZPass installations have been very successful at decreasing wait times at toll plazas, with further decreases in congestion possible through the use of high speed E-ZPass lanes, which can collect fares at near highway speed.

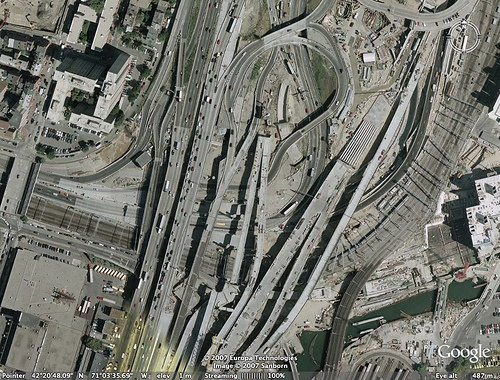

Living in Massachusetts, one topic related to transportation engineering that has always been of great interest to me is the Boston Central Artery/Tunnel Project, more commonly known as the Big Dig. Completed in 2007 after 25 years of planning and work, the primary purpose of this massive project was to move the Central Artery (Interstate 93) from an elevated highway to a tunnel under the city of Boston. Costing in excess of $14 billion, it is the most expensive highway project in US history, and its cost will likely continue to rise as a result of flaws in construction.

Living in Massachusetts, one topic related to transportation engineering that has always been of great interest to me is the Boston Central Artery/Tunnel Project, more commonly known as the Big Dig. Completed in 2007 after 25 years of planning and work, the primary purpose of this massive project was to move the Central Artery (Interstate 93) from an elevated highway to a tunnel under the city of Boston. Costing in excess of $14 billion, it is the most expensive highway project in US history, and its cost will likely continue to rise as a result of flaws in construction.

The dictionary tells us that engineering is “The branch of science and technology concerned with the design, building, and use of engines, machines, and structures”. While this definition might be satisfactory to some, there is much more to engineering than one simple sentence can describe. This brief definition leaves out one of the most critical parts of engineering in my opinion; problem solving. Sure engineers design, build, and use all sorts of things, but we also spend a huge about of time troubleshooting the things that are already built that don’t work right, or that could be improved. We look to improve the usability, efficiency, and sustainability of things that do work right, but could be better. Engineers also analyze the impact of our work on other engineered items, on the general population, and on our world. Additionally, the dictionary’s definition of what engineers design, build, and use is totally oversimplified. In fact, I don’t think it would be a stretch to say that engineering is involved in the design, construction, and use of everything. If an engineer hasn’t been involved in the creation of a certain product or item, chances are it isn’t going to work the way it is intended. Engineering is a discipline that can be found everywhere, and drastically impacts our lives every day.

The dictionary tells us that engineering is “The branch of science and technology concerned with the design, building, and use of engines, machines, and structures”. While this definition might be satisfactory to some, there is much more to engineering than one simple sentence can describe. This brief definition leaves out one of the most critical parts of engineering in my opinion; problem solving. Sure engineers design, build, and use all sorts of things, but we also spend a huge about of time troubleshooting the things that are already built that don’t work right, or that could be improved. We look to improve the usability, efficiency, and sustainability of things that do work right, but could be better. Engineers also analyze the impact of our work on other engineered items, on the general population, and on our world. Additionally, the dictionary’s definition of what engineers design, build, and use is totally oversimplified. In fact, I don’t think it would be a stretch to say that engineering is involved in the design, construction, and use of everything. If an engineer hasn’t been involved in the creation of a certain product or item, chances are it isn’t going to work the way it is intended. Engineering is a discipline that can be found everywhere, and drastically impacts our lives every day. Civil engineering is a subset within engineering that deals primarily with infrastructure. This includes roads, bridges, buildings, utilities, railways, ports, tunnels, and much more. The name, civil engineering, comes from the early separation between engineering for the military, and engineering for civilians. Almost everything that civilians use each day, the infrastructure that is critical to our society as we know it is the responsibility of civil engineers. We also focus a great deal on managing the use of the systems that we build, from traffic control to water resource management. Civil engineers work to ensure not only that the systems that our population requires are in place, but also that they are functioning as intended and in an efficient manner. Civil engineering has a number of sub disciplines that focus on specific areas of the civil engineering field. Each sub discipline plays an important role in the overall field of civil engineering.

Civil engineering is a subset within engineering that deals primarily with infrastructure. This includes roads, bridges, buildings, utilities, railways, ports, tunnels, and much more. The name, civil engineering, comes from the early separation between engineering for the military, and engineering for civilians. Almost everything that civilians use each day, the infrastructure that is critical to our society as we know it is the responsibility of civil engineers. We also focus a great deal on managing the use of the systems that we build, from traffic control to water resource management. Civil engineers work to ensure not only that the systems that our population requires are in place, but also that they are functioning as intended and in an efficient manner. Civil engineering has a number of sub disciplines that focus on specific areas of the civil engineering field. Each sub discipline plays an important role in the overall field of civil engineering.