There are many risks associated with the fabrication and testing of any large scale design project. Throughout the process, we will be interacting with materials and devices that pose safety concerns to the individuals involved. In order to mitigate these concerns, the team will be adhering to all documented safety procedures outlined by Lafayette College. These procedures include chemical hygiene plans, electrical safety documents, general lab safety, and covid protocols. List below are some important documents and their relevance to this project.

Acopian 4th Floor Lab Safety Procedures

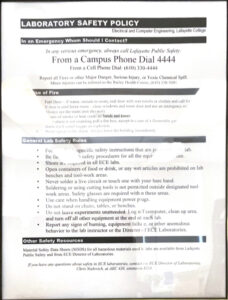

Lab work can be extremely dangerous and precautions must be taken to prevent injury. A general lab safety document is hanging on the wall of each lab on the electrical and computer engineering floor. It lists emergency contacts, fire procedures, and general rules to be followed while in the lab.

Lab work can be extremely dangerous and precautions must be taken to prevent injury. A general lab safety document is hanging on the wall of each lab on the electrical and computer engineering floor. It lists emergency contacts, fire procedures, and general rules to be followed while in the lab.

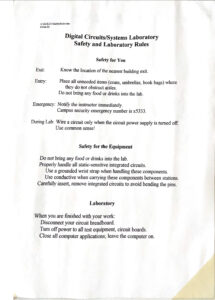

The digital circuits laboratory has a specific safety policy as well. It lists similar rules and procedures but more specific for the digital circuits equipment.

The digital circuits laboratory has a specific safety policy as well. It lists similar rules and procedures but more specific for the digital circuits equipment.

The soldering lab also has a specific safety document for proper operation of the soldering irons and procedures for emergencies. It is important to follow these rules to avoid fires or severe burns.

The soldering lab also has a specific safety document for proper operation of the soldering irons and procedures for emergencies. It is important to follow these rules to avoid fires or severe burns.

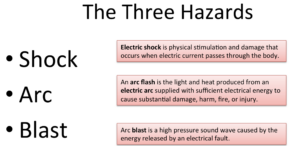

Lastly, a PowerPoint on the topic of electrical safety is provided on the Senior Design Moodle. This document addresses the dangers of shock, arc, and flash using data from studies and provides general rules and mitigation strategies for avoiding injury.

Lastly, a PowerPoint on the topic of electrical safety is provided on the Senior Design Moodle. This document addresses the dangers of shock, arc, and flash using data from studies and provides general rules and mitigation strategies for avoiding injury.

HazardsOfElectricity-withrules

Leopard Works

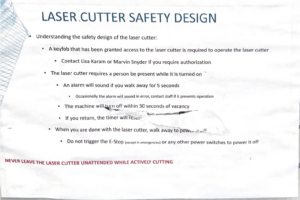

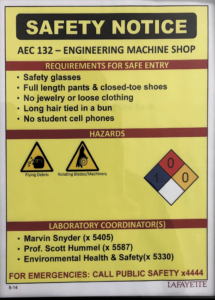

LeopardWorks houses many sophisticated engineering machines that will be used throughout the fabrication of the robot. Students will follow all posted instructions on the equipment to avoid damage. Safety information is posted on the door of the facility and is also documented below.

LeopardWorks houses many sophisticated engineering machines that will be used throughout the fabrication of the robot. Students will follow all posted instructions on the equipment to avoid damage. Safety information is posted on the door of the facility and is also documented below.

A log of all machine usage will be kept in the Google Drive to document the success or failure of a given project. The log will also include a spot for the amount of the machines were used in a given session.

Acopian Machine Shop

The machine shop will be an integral part of the fabrication of AuBi. While members of the team will not personally be operating the equipment in the machine shop, it is important to keep in mind the posted safety rules for entry into the room.

The machine shop will be an integral part of the fabrication of AuBi. While members of the team will not personally be operating the equipment in the machine shop, it is important to keep in mind the posted safety rules for entry into the room.

Chemical Hygiene Plan (CHP)

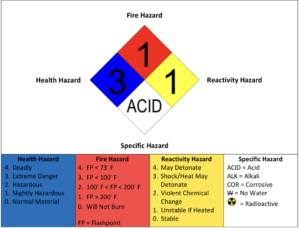

Lafayette college has prepared a chemical hygiene plan for use in any on campus lab or workspace in which hazardous materials and substances are used. The CHP lists actions and methods to help prevent any unwanted chemical accidents. As electrical and computer engineers, we are not often in the presence of hazardous chemicals. For this project specifically, the CHP will be referenced for battery storage and usage. The CHP will also be consulted in the event of a battery spill or leak. It also contains a reference for how to read the NFPA’s room safety triangle.

Lafayette college has prepared a chemical hygiene plan for use in any on campus lab or workspace in which hazardous materials and substances are used. The CHP lists actions and methods to help prevent any unwanted chemical accidents. As electrical and computer engineers, we are not often in the presence of hazardous chemicals. For this project specifically, the CHP will be referenced for battery storage and usage. The CHP will also be consulted in the event of a battery spill or leak. It also contains a reference for how to read the NFPA’s room safety triangle.

Chemical-Hygiene-Plan-Lafayette-College

Electrical Safety Program

The first of two electrical safety documents created by the college is the electrical safety program document. The document outlines mitigation strategies to prevent electrical shock or injury from electrical components. People are split into groups of qualified and unqualified workers. Anyone with training or a relevant degree is considered a qualified electrical worker and thus is allowed to perform work on electrical systems. The most relevant parts of the electrical safety program are in the appendices.

Appendix A – Electrical Hazards

Appendix B – Electrical Hazard Prevention

Appendix C – Capacitor Discharge

Appendix D – Electrical Fires

Appendix E – Ground Fault Circuit Interruptors (GFIs)

Appendix F – Extension Cords