Sustainable production of fuels and chemicals requires the use of renewable feedstocks and green processing. Current research focuses on the use of biomass based feedstocks for the reduced impact production of biodiesel and products.

Biobased polymers using green solvents

Creating polymers with biobased materials circumvents the need to rely on petroleum feedstocks and potentially allows for increase polymer performance and end-of-life properties. This collaborative project (with Dr. Melissa Gordon and Dr. Joseph Stanzione) seeks to create polyesters from birch bark materials. Our focus is the use of green solvents to enable more sustainable monomer extraction and polymerization.

Creating polymers with biobased materials circumvents the need to rely on petroleum feedstocks and potentially allows for increase polymer performance and end-of-life properties. This collaborative project (with Dr. Melissa Gordon and Dr. Joseph Stanzione) seeks to create polyesters from birch bark materials. Our focus is the use of green solvents to enable more sustainable monomer extraction and polymerization.

Switchable Solvents for Biomass Extraction

Biomass extractions are typically difficult separations due to the complexity of the biomass matrix. Switchable solvents potentially offer a way to provide more selective extractions for biomass fractions within the context of a biorefinery. This project seeks to characterize and optimize the use of switchable hydrophilicity solvents for biomass fractionation

Biomass extractions are typically difficult separations due to the complexity of the biomass matrix. Switchable solvents potentially offer a way to provide more selective extractions for biomass fractions within the context of a biorefinery. This project seeks to characterize and optimize the use of switchable hydrophilicity solvents for biomass fractionation

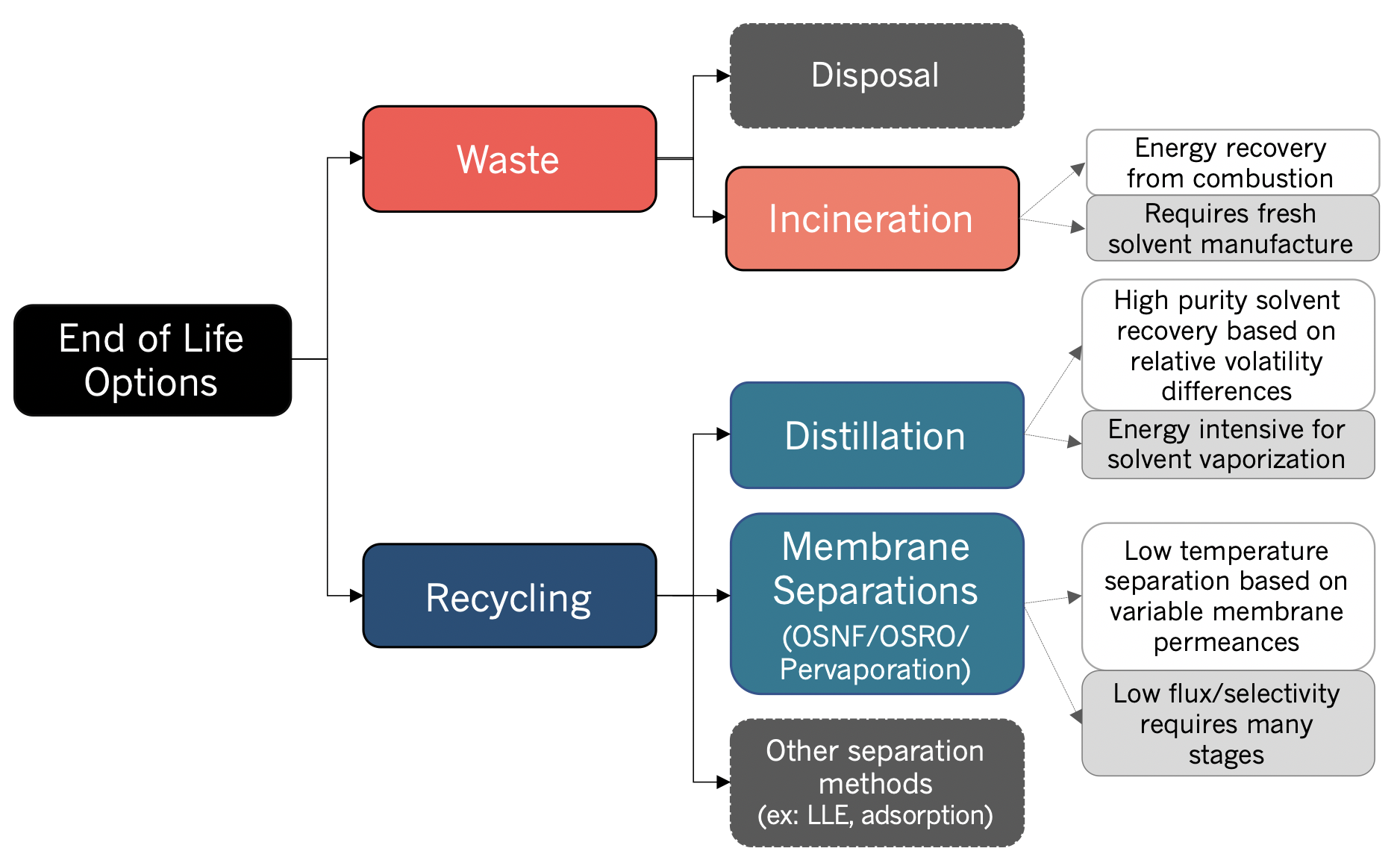

Green Solvent Selection:

Solvent production is energetically demanding, and often has adverse environmental effects. Efficiently disposing of or recycling solvent waste from chemical processes is crucial to minimize industrial energy use, however most streamlined methods for determining solvent sustainability do not consider these process considerations or type of separation method used for recycling. This projects seeks to provide recommendations for solvent end-of-life options using chemical thermophysical properties as robust yet simple metrics for determining process impacts.

Biodiesel Cold Flow Properties

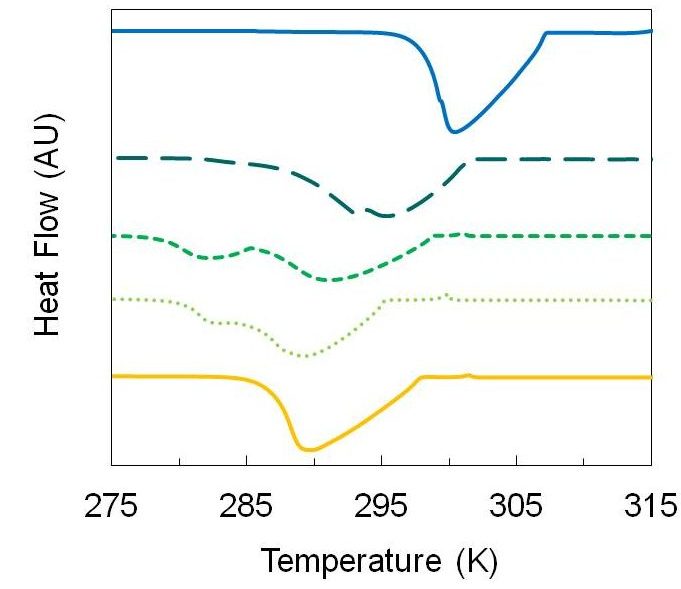

While a promising replacement for petroleum-based diesel fuel, biodiesel suffers from poor cold flow properties, which can inhibit their use in cold weather applications. This research provides a systematic approach towards analyzing the cold flow properties of model fuels with biobased fuel additives in order to establish the structure property relationships between individual biodiesel components as well as the possibility of using sustainably based fuel improvers.

While a promising replacement for petroleum-based diesel fuel, biodiesel suffers from poor cold flow properties, which can inhibit their use in cold weather applications. This research provides a systematic approach towards analyzing the cold flow properties of model fuels with biobased fuel additives in order to establish the structure property relationships between individual biodiesel components as well as the possibility of using sustainably based fuel improvers.

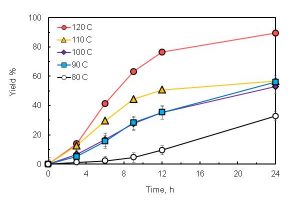

Acid Catalyzed Biodiesel Interesterification

A major by-product of biodiesel production is glycerol. While there are commercial uses for glycerol, the volume that would be produced for large scale biodiesel production would saturate the glycerol market. Therefore finding alternatives to glycerol production could potentially add value to fuel production. This work seeks to optimize biodiesel interesterification using heterogeneous acid catalysts for an improved biodiesel production process.